Content Menu

● Introduction to Extrusion Technology

>> Automatic Extrusion Machines

>>> Key Features of Automatic Extrusion Machines

● Latest Innovations in Extrusion Technology

>> 1. Integration of AI and Machine Learning

>> 2. Advanced Automation and Robotics

>> 3. Sustainable Materials and Practices

>> 4. Integration with 3D Printing

>> 5. Industry 4.0 and Digitalization

● Applications of Automatic Extrusion Machines

>> 1. Plastic Processing

>> 2. Food and Pharmaceuticals

>> 3. Aluminum Extrusion

● Future Prospects and Challenges

>> Impact of Emerging Technologies

>> Global Market Trends

● Conclusion

● FAQ

>> 1. What are the key benefits of using automatic extrusion machines?

>> 2. How does AI contribute to extrusion technology?

>> 3. What role does sustainability play in modern extrusion processes?

>> 4. How does the integration of 3D printing with extrusion enhance manufacturing capabilities?

>> 5. What are the future prospects for the extrusion machinery market?

The field of extrusion technology has witnessed significant advancements in recent years, particularly with the integration of automation and artificial intelligence (AI) into extrusion machines. These innovations have transformed the manufacturing landscape by enhancing efficiency, precision, and sustainability. In this article, we will delve into the latest developments in automatic extrusion machines, exploring their applications, benefits, and future prospects.

Introduction to Extrusion Technology

Extrusion is a manufacturing process where raw materials, such as plastics or metals, are forced through a die to create a continuous profile. This process is widely used in various industries, including construction, automotive, and packaging. The evolution of extrusion technology has led to the development of more sophisticated and automated systems, which are crucial for meeting the demands of modern manufacturing.

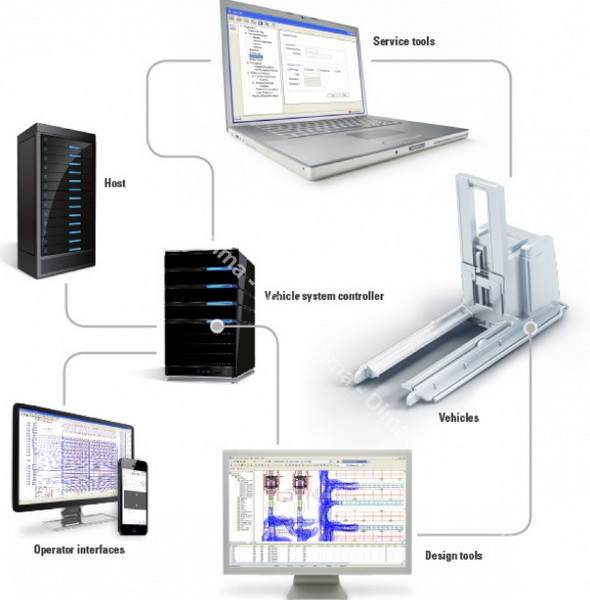

Automatic Extrusion Machines

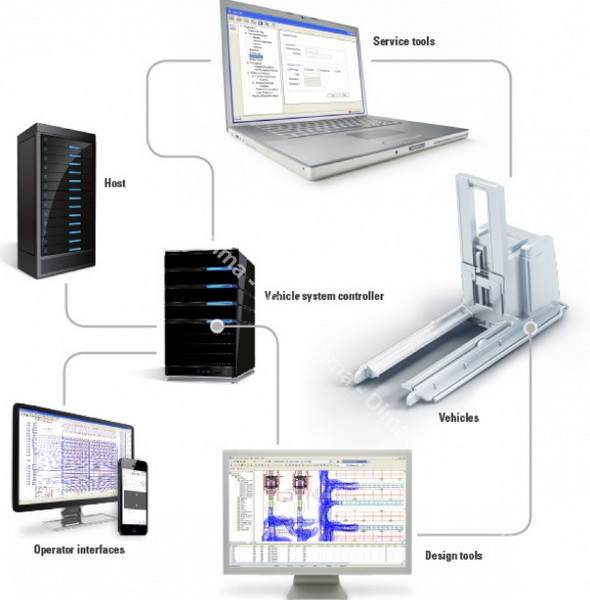

Automatic extrusion machines are designed to streamline the production process by minimizing manual intervention. These machines integrate advanced technologies such as robotics, AI, and IoT to optimize production efficiency and product quality. The use of automation in extrusion allows for real-time monitoring and adjustments, ensuring consistent output and reducing waste.

Key Features of Automatic Extrusion Machines

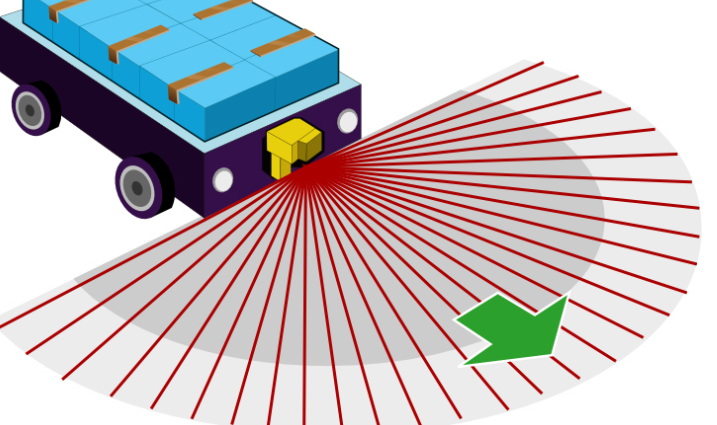

1. High Precision and Consistency: Automatic extrusion machines utilize advanced sensors and AI algorithms to maintain precise control over the extrusion process, ensuring consistent product quality. This level of precision is particularly important in industries where product uniformity is critical, such as in the production of medical devices or automotive parts.

2. Efficient Material Handling: Robotics and automated systems handle material feeding and positioning, reducing human error and improving safety. This automation also allows for faster production cycles and better resource allocation.

3. Sustainability: These machines often incorporate sustainable practices, such as energy-efficient designs and the use of recycled materials. The emphasis on sustainability aligns with global environmental goals and helps reduce operational costs.

Latest Innovations in Extrusion Technology

1. Integration of AI and Machine Learning

The integration of AI and machine learning has revolutionized the extrusion process by enabling real-time monitoring and adjustments. AI algorithms can analyze production data to optimize process parameters, improve product quality, and reduce waste. For instance, AI can predict potential defects and adjust the extrusion conditions to prevent them, thereby enhancing overall efficiency.

2. Advanced Automation and Robotics

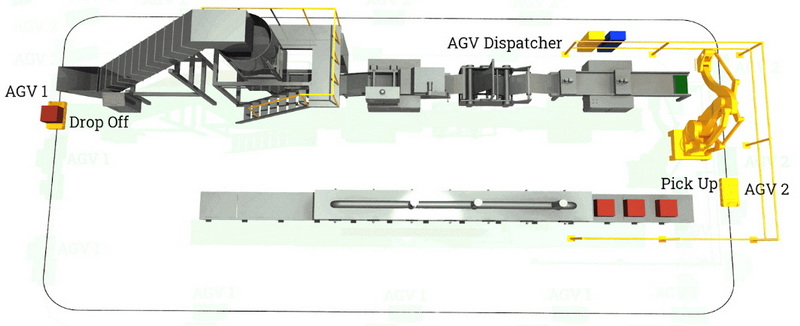

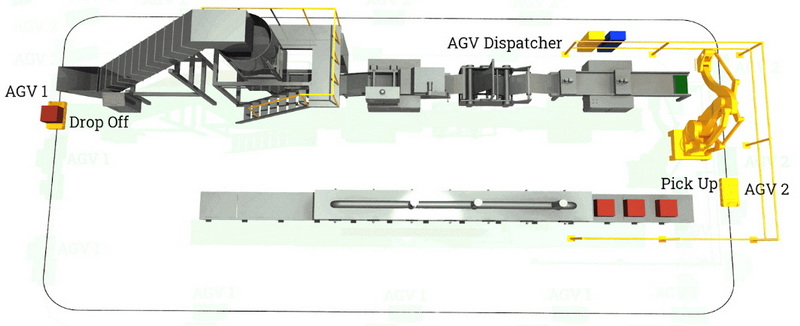

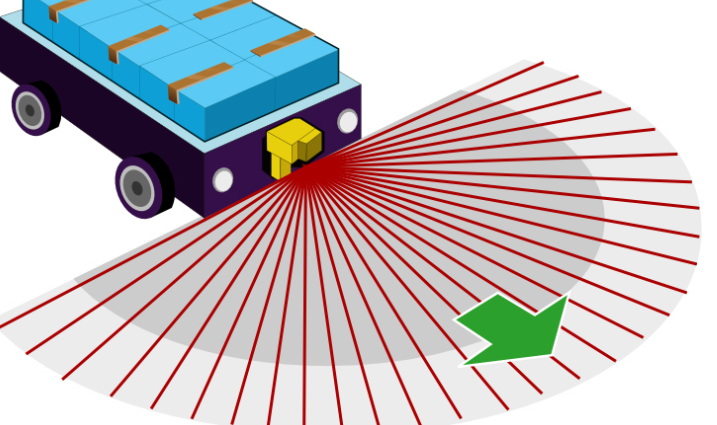

Automation and robotics play a crucial role in modern extrusion machines. They handle tasks such as material transport and positioning with high precision, reducing errors and improving safety. Robotics also enable the handling of complex tasks that were previously challenging or impossible for manual labor.

3. Sustainable Materials and Practices

There is a growing emphasis on sustainable materials and practices in extrusion. Bioplastics and recycled materials are increasingly used to reduce environmental impact. This shift towards sustainability not only aligns with environmental regulations but also appeals to consumers who prioritize eco-friendly products.

4. Integration with 3D Printing

The integration of extrusion with 3D printing technologies offers new possibilities for complex geometries and customized products. This combination allows manufacturers to produce parts with intricate designs that cannot be achieved through traditional extrusion methods alone.

5. Industry 4.0 and Digitalization

The adoption of Industry 4.0 technologies, such as data analytics and digital twinning, enhances efficiency and predictive maintenance in extrusion processes. Digital twins allow for virtual testing and optimization of production lines before actual implementation, reducing downtime and improving overall performance.

Applications of Automatic Extrusion Machines

Automatic extrusion machines are versatile and find applications across various industries:

1. Plastic Processing

Plastic extrusion machines are widely used for producing packaging materials, construction components, and automotive parts. The use of automation in plastic extrusion ensures consistent quality and reduces production costs.

2. Food and Pharmaceuticals

Extrusion technology is also used in the food and pharmaceutical industries for producing high-quality, hygienically manufactured products. In these sectors, precision and cleanliness are paramount, making automation a critical component.

3. Aluminum Extrusion

Aluminum extrusion machines are crucial for producing lightweight yet strong components used in aerospace, construction, and automotive sectors. The precision and efficiency of automatic extrusion machines are essential for meeting the stringent quality standards in these industries.

Future Prospects and Challenges

The future of automatic extrusion machines looks promising, with ongoing advancements in technology and increasing demand for sustainable and efficient manufacturing processes. However, challenges such as fluctuating raw material prices and stringent environmental regulations must be addressed. Manufacturers will need to adapt to these challenges by investing in research and development and adopting innovative technologies.

Impact of Emerging Technologies

Emerging technologies like blockchain and the Internet of Things (IoT) are expected to further enhance the efficiency and transparency of extrusion processes. Blockchain can ensure traceability and authenticity of materials, while IoT can provide real-time data for better decision-making.

Global Market Trends

The global market for extrusion machinery is expected to grow significantly, driven by technological innovations, increasing automation, and rising demand for extruded products. Regions with strong manufacturing bases, such as Asia and Europe, are likely to lead this growth.

Conclusion

Automatic extrusion machines have revolutionized the manufacturing landscape by offering enhanced efficiency, precision, and sustainability. As technology continues to evolve, we can expect even more sophisticated and environmentally friendly extrusion processes. The integration of AI, automation, and sustainable materials will play a crucial role in shaping the future of extrusion technology.

FAQ

1. What are the key benefits of using automatic extrusion machines?

- Answer: Automatic extrusion machines offer several benefits, including high precision and consistency, efficient material handling, reduced waste, and improved safety. They also enable real-time monitoring and adjustments, ensuring consistent product quality.

2. How does AI contribute to extrusion technology?

- Answer: AI contributes to extrusion technology by enabling real-time monitoring and adjustments. AI algorithms can analyze production data to optimize process parameters, improve product quality, and reduce waste.

3. What role does sustainability play in modern extrusion processes?

- Answer: Sustainability plays a significant role in modern extrusion processes through the use of bioplastics, recycled materials, and energy-efficient designs. These practices help reduce environmental impact and align with global sustainability goals.

4. How does the integration of 3D printing with extrusion enhance manufacturing capabilities?

- Answer: The integration of 3D printing with extrusion allows for the creation of complex geometries and customized products. This combination opens up new possibilities for manufacturing, enabling the production of parts that were previously difficult or impossible to extrude.

5. What are the future prospects for the extrusion machinery market?

- Answer: The extrusion machinery market is expected to grow significantly, driven by technological innovations, increasing automation, and rising demand for extruded products. The market will continue to evolve with advancements in AI, Industry 4.0 technologies, and sustainable practices.