Content Menu

● Introduction

● Current Anti-Dumping Regulations

● Impact on the Aluminum Industry

>> Market Trends and Pricing Implications

● Case Studies

● Future Outlook

● Conclusion

● Related Questions

>> 1. What are anti-dumping duties, and how do they affect the aluminum industry?

>> 2. How can businesses prepare for changes in aluminum extrusion regulations?

>> 3. What are the implications of anti-dumping investigations for consumers?

>> 4. How do global trade dynamics influence aluminum extrusion prices?

>> 5. What role does sustainability play in the future of the aluminum extrusion industry?

Introduction

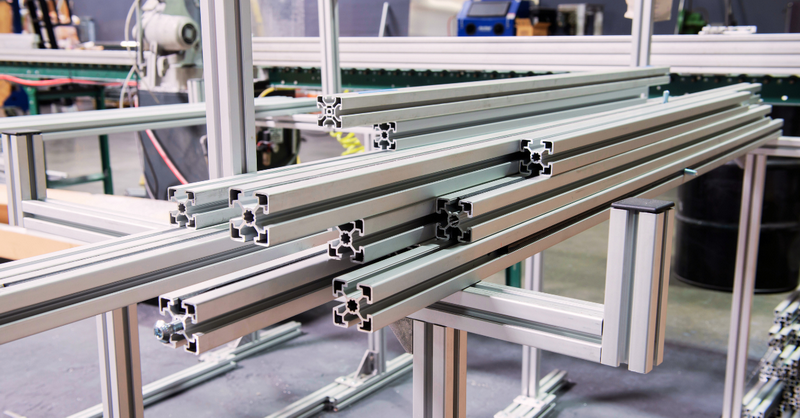

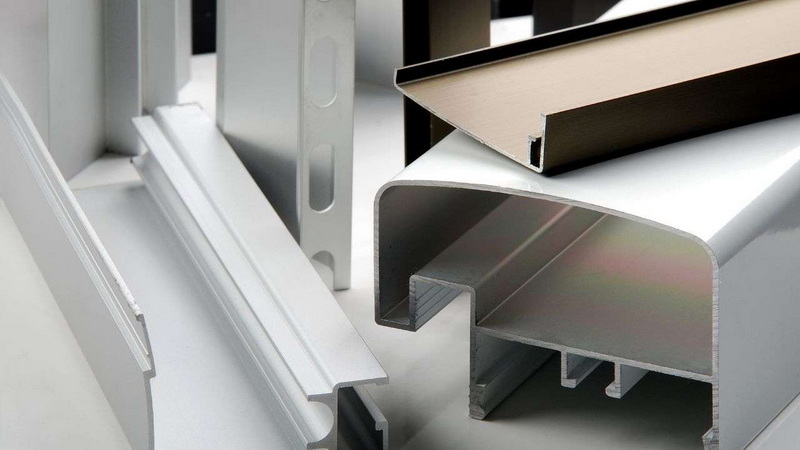

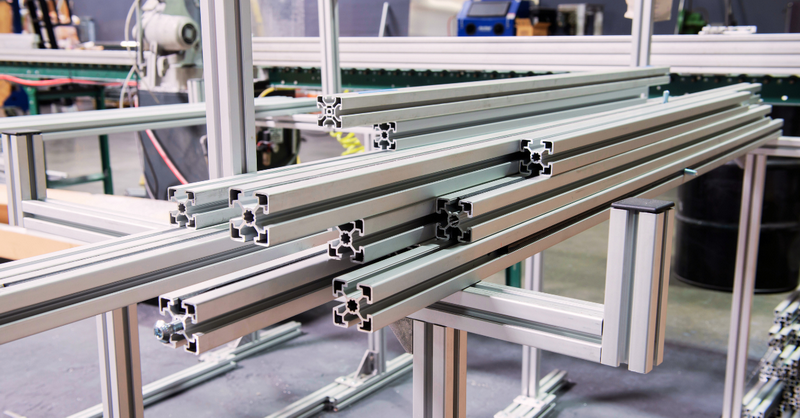

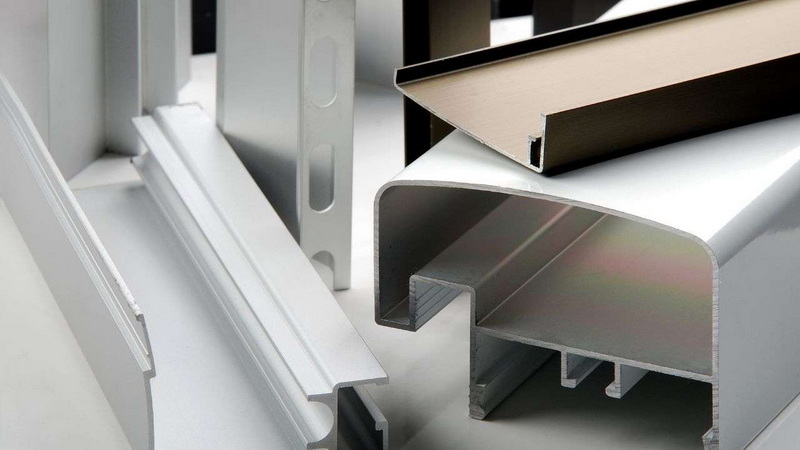

Aluminum extrusion is a vital process in the manufacturing industry, allowing for the creation of complex shapes and profiles that are essential in various applications, from construction to automotive. However, the global aluminum market has faced significant challenges due to anti-dumping regulations. These measures are designed to protect domestic industries from unfair competition posed by foreign imports that are sold at below-market prices. This article explores the latest developments in aluminum extrusion anti-dumping regulations, their implications for the industry, and what businesses need to know to navigate this complex landscape.

Current Anti-Dumping Regulations

In recent years, several countries have implemented or updated anti-dumping duties on aluminum extrusions, particularly targeting imports from countries like China and Vietnam. These regulations are often a response to allegations that foreign manufacturers are selling aluminum products at prices lower than their production costs, which can undermine local businesses.

The U.S. Department of Commerce has been particularly active in investigating these claims. In 2023, new tariffs were imposed on aluminum extrusions imported from specific countries, significantly impacting the pricing and availability of these products in the U.S. market. The regulations not only affect the cost of aluminum extrusions but also influence the supply chain dynamics, as manufacturers must adapt to the changing landscape of tariffs and duties.

Impact on the Aluminum Industry

The introduction of anti-dumping duties has far-reaching consequences for the aluminum industry. For manufacturers, these regulations can lead to increased production costs, as they may need to source materials from more expensive domestic suppliers or invest in compliance measures to meet regulatory standards. This can ultimately result in higher prices for consumers.

Moreover, the aluminum extrusion market has seen a shift in demand patterns. As import prices rise due to tariffs, domestic manufacturers may experience a temporary boost in sales. However, this is often accompanied by increased scrutiny and compliance costs, which can strain smaller businesses that lack the resources to navigate complex regulatory environments.

Market Trends and Pricing Implications

The aluminum extrusion market is currently experiencing volatility due to these regulatory changes. Prices for aluminum extrusions have fluctuated, with some manufacturers passing on the increased costs to consumers. This has led to a mixed response from the market, with some sectors seeing growth while others struggle to maintain profitability.

Additionally, the global nature of the aluminum supply chain means that changes in one region can have ripple effects worldwide. For instance, if U.S. manufacturers face higher costs due to anti-dumping duties, they may seek to source materials from other countries, potentially leading to increased competition in those markets.

Case Studies

Recent anti-dumping investigations have highlighted the complexities of the aluminum extrusion market. For example, a notable case involved a major U.S. manufacturer that filed a complaint against Chinese producers, alleging that they were selling aluminum extrusions at unfairly low prices. The investigation revealed significant discrepancies in pricing and led to the imposition of substantial tariffs on imports from China.

Another case involved Vietnam, where U.S. authorities found that certain aluminum extrusions were being sold below market value. This resulted in a series of investigations and the eventual implementation of anti-dumping duties, which have since affected the availability of these products in the U.S. market.

These case studies illustrate the ongoing challenges faced by manufacturers and importers in the aluminum extrusion sector. As investigations continue and new regulations are introduced, businesses must remain vigilant and adaptable to survive in this competitive landscape.

Future Outlook

Looking ahead, the aluminum extrusion market is likely to continue facing challenges related to anti-dumping regulations. As global trade dynamics shift and countries respond to domestic pressures, businesses must be prepared for potential changes in tariffs and duties.

One possible outcome is the introduction of more stringent compliance measures, which could further complicate the importation of aluminum extrusions. Companies may need to invest in legal and regulatory expertise to navigate these complexities effectively.

Moreover, as sustainability becomes a more pressing concern, the aluminum industry may see a shift towards more environmentally friendly practices. This could include increased recycling efforts and the development of new materials that comply with both regulatory standards and consumer demand for sustainable products.

Conclusion

The landscape of aluminum extrusion anti-dumping regulations is continually evolving, with significant implications for manufacturers, importers, and consumers alike. As businesses navigate these challenges, staying informed about regulatory changes and market trends will be crucial for success. The aluminum industry must adapt to these developments, balancing compliance with innovation to thrive in a competitive global market.

Related Questions

1. What are anti-dumping duties, and how do they affect the aluminum industry?

Anti-dumping duties are tariffs imposed on foreign imports that are believed to be priced below fair market value. These duties aim to protect domestic industries from unfair competition, impacting pricing and availability in the aluminum sector.

2. How can businesses prepare for changes in aluminum extrusion regulations?

Businesses can prepare by staying informed about regulatory updates, investing in compliance measures, and seeking legal expertise to navigate the complexities of anti-dumping laws.

3. What are the implications of anti-dumping investigations for consumers?

Consumers may face higher prices for aluminum extrusions as manufacturers pass on increased costs due to tariffs. Additionally, the availability of certain products may be affected.

4. How do global trade dynamics influence aluminum extrusion prices?

Global trade dynamics, including tariffs and anti-dumping regulations, can lead to fluctuations in aluminum extrusion prices as manufacturers adjust their sourcing and pricing strategies in response to regulatory changes.

5. What role does sustainability play in the future of the aluminum extrusion industry?

Sustainability is becoming increasingly important in the aluminum extrusion industry, with a focus on recycling and environmentally friendly practices. Companies that prioritize sustainability may gain a competitive edge in the market.