Content Menu

● Introduction to Film Extrusion Machinery

● Technological Advancements in Film Extrusion Machinery

>> 1. Integration of Artificial Intelligence (AI)

>> 2. Multi-Layer Co-Extrusion Technology

>> 3. Automation and IoT Integration

>> 4. Sustainable Innovations

>> 5. Enhanced Cooling Systems

● Blown Film vs. Cast Film Extrusion

● Key Components of Modern Film Extrusion Machinery

● Applications of Film Extrusion Machinery

>> 1. Packaging Industry

>> 2. Agricultural Films

>> 3. Construction Materials

● Challenges in Film Extrusion Machinery

● Conclusion

● FAQs

>> 1. What is film extrusion machinery?

>> 2. What are the differences between blown film and cast film extrusion?

>> 3. How has AI impacted film extrusion machinery?

>> 4. What sustainable innovations are being adopted?

>> 5. What industries benefit from film extrusion technology?

● Citations:

The film extrusion machinery industry is undergoing rapid advancements, driven by technological innovations, sustainability efforts, and the growing demand for high-quality plastic films in various sectors. This article explores the latest developments in film extrusion machinery, including cutting-edge technologies, enhanced efficiency, and sustainable solutions.

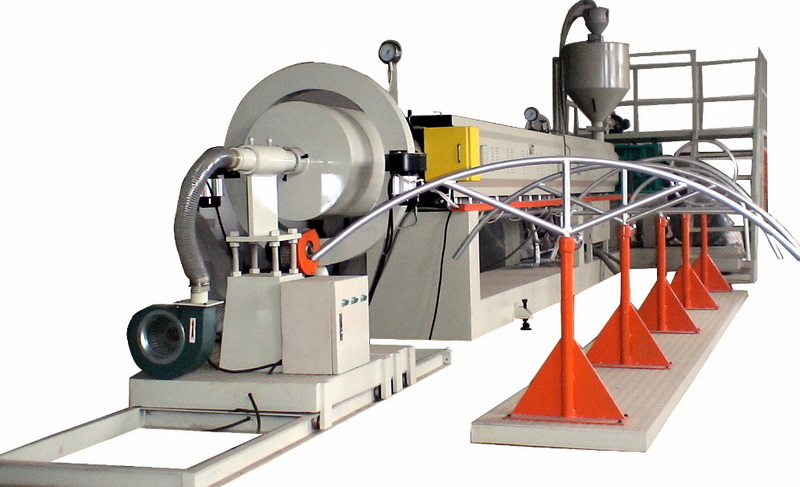

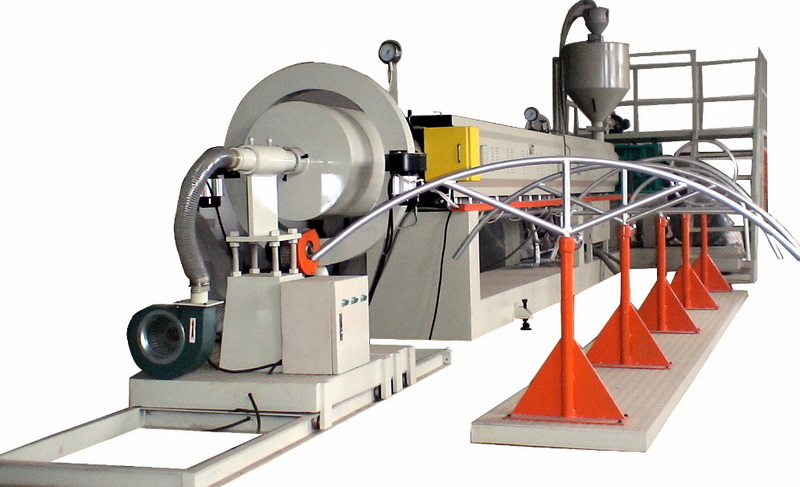

Introduction to Film Extrusion Machinery

Film extrusion machinery is essential for manufacturing plastic films used in packaging, agriculture, construction, and more. The process involves melting plastic materials and shaping them into thin films through either blown or cast film extrusion methods. These machines are integral to producing films with specific properties such as strength, clarity, and flexibility.

Technological Advancements in Film Extrusion Machinery

1. Integration of Artificial Intelligence (AI)

AI has revolutionized film extrusion by enabling real-time monitoring and optimization of processing parameters like temperature and pressure. This results in:

- Improved product quality

- Reduced material waste

- Enhanced energy efficiency[1][4].

2. Multi-Layer Co-Extrusion Technology

Modern film extrusion lines can now produce up to 11-layer films using advanced co-extrusion die heads. These multi-layer films combine different materials to achieve superior barrier properties and mechanical strength[9].

3. Automation and IoT Integration

Automation systems equipped with IoT sensors allow manufacturers to monitor key metrics such as line speed and material flow remotely. This ensures consistent production quality while reducing downtime[2][4].

4. Sustainable Innovations

The industry is shifting towards eco-friendly solutions such as:

- Biodegradable films made from PBAT and PE blends

- Recycling post-consumer plastic waste into new films using advanced extrusion lines[9].

5. Enhanced Cooling Systems

High-speed cooling systems have been introduced to expedite the solidification process, improving production rates without compromising film quality[4].

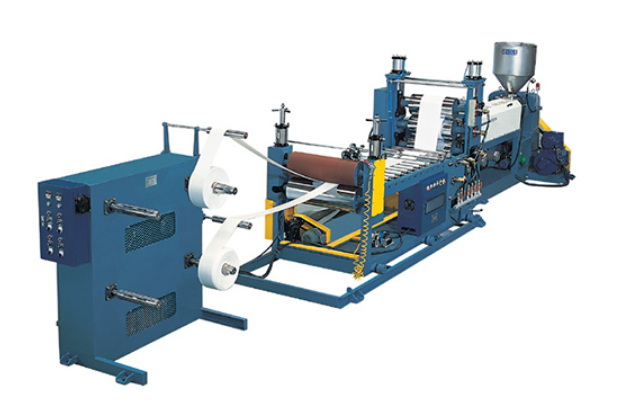

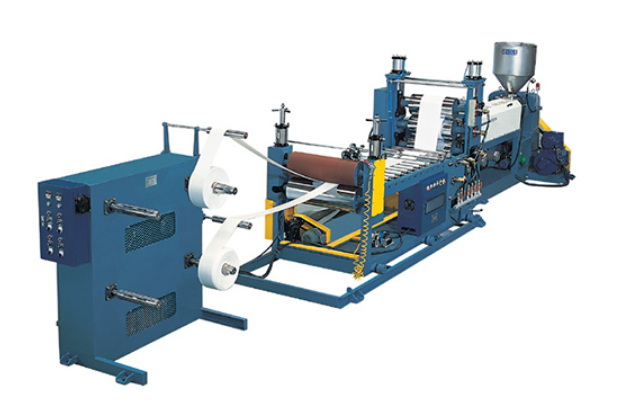

Blown Film vs. Cast Film Extrusion

| Feature | Blown Film Extrusion | Cast Film Extrusion |

| Process | Inflates molten plastic into a bubble | Flattens molten plastic onto a chill roll |

| Applications | Packaging bags, shrink wraps | High-clarity films for food packaging |

| Advantages | Uniform thickness, biaxial strength | High clarity, faster production rates |

| Popular Materials | PE, PP | PE, PVC |

Both methods have unique advantages and are chosen based on specific application needs[6][7].

Key Components of Modern Film Extrusion Machinery

1. Extruders: Melt and mix raw materials with additives.

2. Die Heads: Shape the molten plastic into desired profiles.

3. Cooling Systems: Solidify the film quickly.

4. Automation Units: Monitor and control parameters for precision.

5. Winders: Roll the finished film for storage or further processing[4][6].

Applications of Film Extrusion Machinery

1. Packaging Industry

Film extrusion is widely used for producing flexible packaging materials like food wraps, shopping bags, and shrink films.

2. Agricultural Films

Specialized equipment produces UV-stabilized films for greenhouses and mulching applications.

3. Construction Materials

Extruded plastic films are used for waterproofing membranes and vapor barriers in construction projects[1][7].

Challenges in Film Extrusion Machinery

Despite advancements, challenges remain:

- High capital investment for advanced machinery

- Skilled labor requirements for operating complex systems

- Fluctuating raw material costs impacting profitability[8].

Conclusion

The latest advancements in film extrusion machinery are transforming the industry by enhancing efficiency, sustainability, and product quality. From AI integration to multi-layer co-extrusion technology, these innovations cater to the growing demand for high-performance plastic films across various sectors.

FAQs

1. What is film extrusion machinery?

Film extrusion machinery melts plastic materials and shapes them into continuous thin films through blown or cast processes. These machines are vital for producing films used in packaging, agriculture, and construction.

2. What are the differences between blown film and cast film extrusion?

Blown film extrusion inflates molten plastic into a bubble for uniform thickness and strength, while cast film extrusion flattens molten plastic onto a chill roll for high clarity.

3. How has AI impacted film extrusion machinery?

AI optimizes processing parameters like temperature and pressure in real-time, improving product quality while reducing waste and energy consumption.

4. What sustainable innovations are being adopted?

The industry is embracing biodegradable films made from PBAT/PE blends and recycling technologies that convert post-consumer waste into new films.

5. What industries benefit from film extrusion technology?

Key industries include packaging (food wraps), agriculture (greenhouse films), construction (waterproof membranes), and automotive (lightweight components).

Citations:

[1] https://www.globenewswire.com/news-release/2025/02/05/3021359/0/en/Plastic-Extrusion-Machine-Market-to-Grow-at-4-7-CAGR-During-2025-2035-Boosting-Global-Industry-to-USD-12-343-2-Million-by-2035-Future-Market-Insights-Inc.html

[2] https://www.pearltechinc.com/2025/02/13/extrusion-equipment-blown-film-efficiency/

[3] https://www.luigibandera.com/unveiling-techno-flex-po5-revolutionizing-extrusion-technology-for-diverse-packaging-solutions/

[4] https://jieyatwinscrew.com/blog/everything-you-need-to-know-about-plastic-extrusion-machines/

[5] https://www.youtube.com/watch?v=R7T2MCJ0Tho

[6] https://www.yjing-extrusion.com/what-is-film-extrusion-equipment-and-how-does-it-work.html

[7] https://viemachinery.com/understanding-blown-film-extrusion-process-equipment-and-uses/

[8] https://www.credenceresearch.com/report/blown-film-extrusion-machine-market

[9] https://www.zjchaoxin.com/blog/blown-film-extrusion-process-applications-and-innovations

[10] https://www.polystarco.com/blog-detail/frequently-asked-questions-about-blown-film-machines/

[11] https://www.chyiyang.com/guide-to-blown-film-extrusion-machines

[12] https://www.plastar-machine.com/en/news/faq.html

[13] https://www.verifiedmarketreports.com/blog/top-7-trends-transforming-the-blown-film-extrusion-lines-market/

[14] https://magazines.amiplastics.com/film-and-sheet-extrusion

[15] https://www.datainsightsmarket.com/reports/pe-stretch-film-making-machine-59702

[16] https://www.prm-taiwan.com/blog/optimized-blown-film-technology-keys-to-sustainable-packaging_464

[17] https://www.bekwell.cn/blogs/top-5-trends-in-film-extrusion-machines-you-need-to-know.html

[18] https://chengheng27.en.made-in-china.com/product/aFSfXgCMApUh/China-2025-Multi-Layer-5-and-7-Layers-Blown-Film-Extrusion-Lines-Best-Performances-Five-Layers-Film-Blowing-Machine.html

[19] https://www.ptonline.com/articles/get-ready-to-be-blown-away-with-new-extrusion-technology

[20] https://www.plasticsmachinerymanufacturing.com/manufacturing/article/55250477/will-the-plastics-machinery-market-rebound-in-2025

[21] https://taiwan.prm-taiwan.com/themes/plastimagenmexico2025/blog/optimizing-multilayer-blown-film--key-factors-advanced-machinery_530/

[22] https://www.swallowmachinery.com/knowledge-base/innovative-applications-of-blown-film-technology

[23] https://www.packagingtechtoday.com/materials/films-coatings/the-future-of-film-design/

[24] https://jieyatwinscrew.com/blog/top-10-plastic-extrusion-machine-manufacturers/

[25] https://www.istockphoto.com/photos/film-extrusion

[26] https://www.instagram.com/polystarmachinery/reel/C-Zv2JqKRNE/

[27] https://www.youtube.com/watch?v=qkUIfVqPAx8

[28] https://www.shutterstock.com/search/extrusion-film

[29] https://www.youtube.com/watch?v=dVk2HVVXMdM

[30] https://chengheng27.en.made-in-china.com/product/EQtrozIcVVRK/China-2025-Three-Layer-Co-Extrusion-Film-Blowing-Unit-ABC-PE-Film-Making-Machine-Made-in-China-ABC-Film-Blowing-Machine.html