Content Menu

● Introduction to Aluminum Extrusion

>> Aluminum Extrusion Process Video

● Key Features of Aluminum Extrusion Handling Equipment

>> 1. Precision and Accuracy

>> 2. Strength and Rigidity

>> 3. Automation and Control

>> 4. Safety Features

>> 5. Maintenance and Upkeep

● Types of Aluminum Extrusion Handling Equipment

>> 1. Extrusion Presses

>> 2. Cooling Systems

>> 3. Cutting and Finishing Equipment

● Emerging Trends and Technologies in Aluminum Extrusion

>> Rapid Extrusion Profile Inspection

>> Rapid Quench Systems

>> Higher Strength Aluminum Alloys

>> Artificial Intelligence Integration

>> Nano-coating Technologies

>> Hybrid Extrusion Techniques

>> Smart Extrusion Lines

● Case Studies: Successful Implementation of Aluminum Extrusion Handling Equipment

● Sustainability and Environmental Impact

● Future of Aluminum Extrusion

● Conclusion

● FAQs

>> 1. What are the primary considerations when selecting aluminum extrusion handling equipment?

>> 2. How does automation impact aluminum extrusion handling?

>> 3. What role does cooling play in the aluminum extrusion process?

>> 4. Can aluminum extrusions be customized for specific applications?

>> 5. What safety precautions should be taken when operating aluminum extrusion equipment?

● Citations:

Aluminum extrusion handling equipment plays a crucial role in the production and processing of aluminum profiles. These profiles are widely used in various industries, including construction, automotive, aerospace, and consumer goods. The efficiency and quality of the final product depend significantly on the capabilities and features of the handling equipment used throughout the extrusion process. In this article, we will explore the key features to look for in aluminum extrusion handling equipment, along with examples and explanations to help guide your selection.

Introduction to Aluminum Extrusion

Aluminum extrusion is a process where aluminum alloy is shaped by pushing it through a mold with a particular cross-sectional design. This process involves a powerful ram that drives the aluminum through the mold, resulting in the material emerging with the desired profile. The process can be divided into several key steps:

1. Preheating the Billet: The aluminum billet is heated to make it malleable.

2. Extrusion: The heated billet is pushed through the die.

3. Cooling: The extruded profile is cooled to set its shape.

4. Stretching and Straightening: The profile is stretched to correct any distortions.

5. Cutting to Length: The profile is cut into specific lengths.

Aluminum Extrusion Process Video

To better understand the extrusion process, watching a video can provide a visual explanation of how aluminum profiles are created.

Key Features of Aluminum Extrusion Handling Equipment

When selecting aluminum extrusion handling equipment, several key features should be considered to ensure efficient and high-quality production.

1. Precision and Accuracy

- Guiding Systems: Ensure precise alignment and movement of profiles during handling.

- Sensors and Monitoring: Use sensors to monitor temperature, pressure, and profile dimensions in real-time.

2. Strength and Rigidity

- Material Selection: Use durable materials for frames and components to withstand heavy loads.

- Structural Integrity: Ensure the equipment can handle the stresses of repeated extrusion cycles.

3. Automation and Control

- PLC Systems: Utilize Programmable Logic Controllers (PLCs) for automated control and monitoring.

- Software Integration: Integrate with production software for streamlined operations and data analysis.

4. Safety Features

- Emergency Stops: Include easily accessible emergency stop buttons.

- Guarding: Provide protective barriers to prevent accidents.

5. Maintenance and Upkeep

- Easy Access: Design equipment for easy maintenance access.

- Regular Checks: Schedule regular inspections to prevent wear and tear.

Types of Aluminum Extrusion Handling Equipment

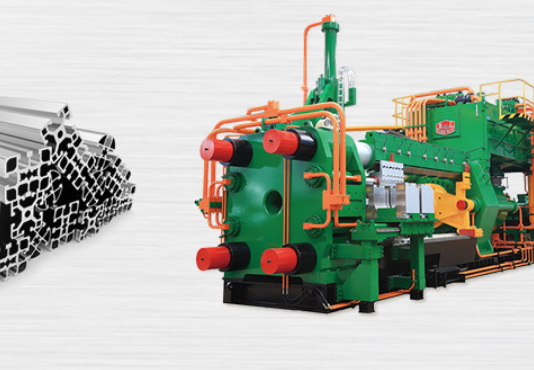

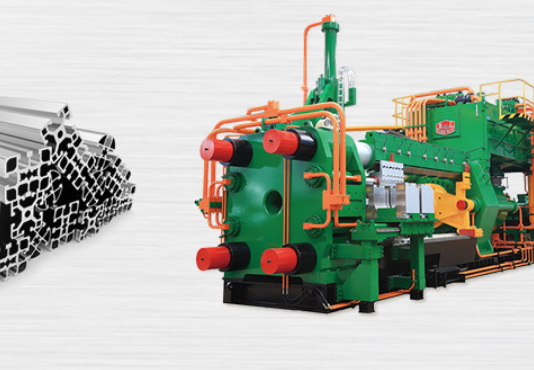

1. Extrusion Presses

- Hydraulic Presses: Suitable for large-scale production with adjustable pressure and speed.

- Toggle Presses: Ideal for smaller profiles with precise control over stroke length.

2. Cooling Systems

- Quenching Tables: Rapidly cool profiles to prevent deformation.

- High-Intensive Quenching: Advanced systems for precise cooling control, featuring adjustable spray nozzles to ensure uniform cooling[1].

3. Cutting and Finishing Equipment

- Sawing Machines: Use carbide-tipped saws for precise cutting.

- Deburring Tools: Remove burrs for smooth finishes.

Emerging Trends and Technologies in Aluminum Extrusion

The aluminum extrusion industry is continuously evolving with technological advancements aimed at improving efficiency, sustainability, and product quality.

Rapid Extrusion Profile Inspection

- Advances in rapid extrusion profile inspection using Computerized Topology (CAT) X-ray scanning are being developed. This technology enhances efficiency and accuracy in quality control by eliminating time-consuming sample preparation[2].

Rapid Quench Systems

- New rapid quench systems utilize multiple nozzles and adjustable flow valves to cool extrusions uniformly, reducing straightness and twist deformations and improving overall product quality[2].

Higher Strength Aluminum Alloys

- The development of higher strength 6000 series aluminum alloys is particularly beneficial for automotive applications where strength and durability are paramount[2].

Artificial Intelligence Integration

- Artificial intelligence is being incorporated into various aspects of the extrusion process, including predictive maintenance, die design, and die correction processes. AI optimizes plant operations and enhances product quality[2][7].

Nano-coating Technologies

- Recent advancements in nano-coating technologies have dramatically enhanced the durability of aluminum extruded profiles by offering an extra layer of protection against corrosion and abrasion[5].

Hybrid Extrusion Techniques

- New hybrid extrusion techniques blend conventional approaches with cutting-edge processes to meet the rising need for aluminum profiles with superior strength and shaping capabilities[5].

Smart Extrusion Lines

- The integration of IoT technology enables comprehensive monitoring and control of the production process, enhancing efficiency and supporting predictive maintenance[5].

Case Studies: Successful Implementation of Aluminum Extrusion Handling Equipment

Several companies have successfully integrated advanced aluminum extrusion handling equipment into their production lines, resulting in increased efficiency and product quality.

- Example 1: A leading automotive parts manufacturer implemented a fully automated extrusion line with PLC-controlled presses and advanced cooling systems. This resulted in a 30% increase in production speed and a significant reduction in defects.

- Example 2: A construction materials supplier upgraded their cutting equipment to include precision sawing machines, reducing waste by 20% and improving finish quality.

- Example 3: An aluminum extruder opted for LPG over traditional fuels for melting furnaces, achieving improved product quality, reduced maintenance, and a cleaner production environment[3].

Sustainability and Environmental Impact

The aluminum extrusion industry is also focusing on reducing its environmental footprint. Efforts include:

- Reducing Carbon Emissions: The industry is making significant strides in reducing carbon emissions across the entire value stream, from mining bauxite to recycling aluminum scrap[2].

- Sustainable Manufacturing Practices: Modern extrusion machines are designed with lower energy consumption and reduced oil leakages, promoting sustainable manufacturing practices[8].

Future of Aluminum Extrusion

As technology continues to advance, the future of aluminum extrusion looks promising. High-pressure extrusion techniques allow for the production of complex, high-strength profiles necessary for critical industries like aerospace and defense[7]. The integration of robotics, AI, and IoT in extrusion lines will further streamline processes, reduce errors, and maximize efficiency[7].

Conclusion

Aluminum extrusion handling equipment is crucial for producing high-quality aluminum profiles efficiently. By focusing on precision, strength, automation, safety, and maintenance, manufacturers can optimize their production processes. Whether it's for construction, automotive, or aerospace applications, selecting the right equipment can significantly impact product quality and production efficiency. The ongoing technological advancements in the industry, including automation, AI integration, and sustainable practices, will continue to transform the landscape of aluminum extrusion.

FAQs

1. What are the primary considerations when selecting aluminum extrusion handling equipment?

- The primary considerations include precision and accuracy, strength and rigidity, automation capabilities, safety features, and ease of maintenance.

2. How does automation impact aluminum extrusion handling?

- Automation enhances control over the extrusion process, improves efficiency, reduces labor costs, and allows for real-time monitoring and adjustments.

3. What role does cooling play in the aluminum extrusion process?

- Cooling is critical as it rapidly quenches the extruded profiles, ensuring they retain their shape and achieve the desired mechanical properties without deformation.

4. Can aluminum extrusions be customized for specific applications?

- Yes, aluminum extrusions can be customized by designing specific dies to meet the exact requirements of the application, allowing for precise placement of material where needed.

5. What safety precautions should be taken when operating aluminum extrusion equipment?

- Safety precautions include ensuring proper training for operators, maintaining a clean workspace, using protective gear, and implementing emergency stop systems.

Citations:

[1] https://aec.org/extrusion-equipment

[2] https://profileprecisionextrusions.com/the-evolution-of-aluminum-extrusions-emerging-trends-and-technologies/

[3] https://www.supergas.com/for-industrial/case-studies/aluminium-extrusion-application

[4] https://www.richardsonmetals.com/innovations-in-aluminum-extrusion-pioneering-precision-and-quality/

[5] https://www.alcircle.com/news/tech-trends-driving-the-aluminium-extrusion-industry-111131

[6] https://grdspublishing.org/index.php/matter/article/download/1489/1404/2029

[7] https://nationalindustries.world/2025/01/02/the-future-of-aluminum-how-extrusion-technology-is-transforming-industries/

[8] https://www.factorytwofour.com/latest-technology-for-aluminum-extrusion/

[9] https://www.westga.edu/~bquest/2016/SWOT2016.pdf

[10] https://kmcaluminium.com/5-machines-essential-for-aluminium-extrusion-production/

[11] https://www.news.market.us/aluminum-extrusion-market-news/

[12] https://www.youtube.com/watch?v=G3agewt3bdU

[13] https://www.pennex.com/press/the-steps-of-aluminum-extrusion

[14] https://jijualuminium.com/aluminum-extrusion-process-and-future-technology-trends/

[15] https://kautec.net/products/extrusion/downstream/

[16] https://www.atieuno.com/2023/10/09/aluminium-extrusion-manufacturers/

[17] https://www.iqsdirectory.com/articles/aluminum-extrusion/extruded-aluminum.html

[18] https://geminigroup.net/understanding-aluminum-extrusion-dies/

[19] https://www.yuhfield.net/en/news/aluminum-extrusion/aluminum-extrusion-applications-benefits

[20] https://stavianmetal.com/en/extruded-aluminum/