Content Menu

● 1. Overview of PP Thick Plate Extrusion

● 2. Key Features to Consider

>> 2.1 High-Efficiency Single-Screw Extruder

>> 2.2 Precision Thickness Control

>> 2.3 Advanced Cooling Systems

>> 2.4 Automation and Control Systems

>> 2.5 Versatility in Applications

● 3. Benefits of Investing in a Quality Production Line

● 4. Challenges in PP Thick Plate Production

● 5. Future Trends in Extrusion Technology

● Conclusion

● FAQ

>> 1. What materials can be processed using a PP thick plate extrusion line?

>> 2. What thickness range can be achieved with PP thick plates?

>> 3. How does recycling work in the extrusion process?

>> 4. What industries benefit from using PP thick plates?

>> 5. Are there any environmental advantages to using PP materials?

● Citations:

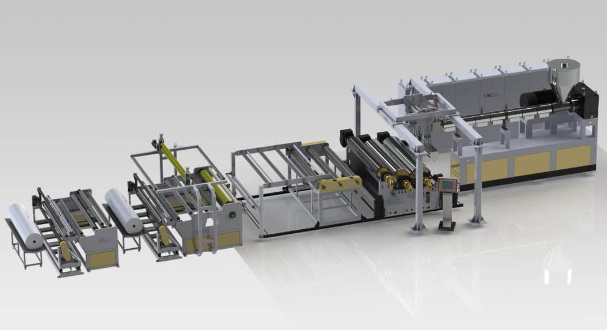

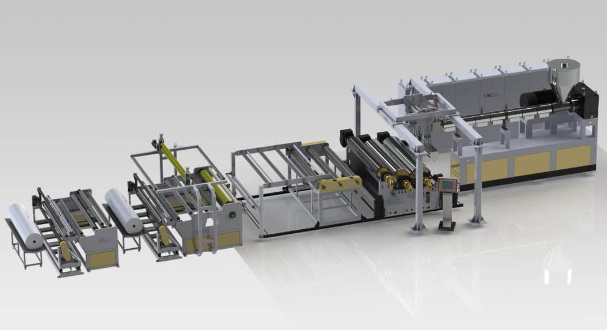

The production of polypropylene (PP) thick plates through extrusion is a crucial process in various industries, including packaging, automotive, and construction. As the demand for high-quality PP thick plates continues to grow, understanding the key features of an effective PP thick plate extrusion production line becomes essential. This article will explore the critical aspects that manufacturers should consider when investing in this technology.

1. Overview of PP Thick Plate Extrusion

PP thick plate extrusion involves melting polypropylene resin and forming it into thick sheets through a continuous process. The production line typically consists of several components:

- Extruder: The heart of the system where the raw PP material is melted and shaped.

- Die: A flat die that shapes the molten material into sheets.

- Cooling System: Cools the sheets to maintain desired thickness and quality.

- Cutting Unit: Cuts the sheets into specified lengths for further processing.

2. Key Features to Consider

When evaluating a PP thick plate extrusion production line, several features are critical to ensuring efficiency, quality, and versatility.

2.1 High-Efficiency Single-Screw Extruder

A high-performance single-screw extruder is essential for producing PP thick plates. It should offer:

- High Output: Capable of processing large volumes of material efficiently.

- Energy Efficiency: Designed to minimize energy consumption while maximizing output.

- Durability: Constructed from high-quality alloy steel to withstand wear and tear.

2.2 Precision Thickness Control

Thickness control is vital for ensuring uniformity in the final product. Key features include:

- Hanger-Type Die Head: A die head with a double-throttle design allows for precise thickness adjustments during production.

- Temperature Control: Advanced temperature control systems that maintain a precision of ±1°C during the extrusion process ensure optimal melting and shaping of the material.

2.3 Advanced Cooling Systems

Cooling systems play a crucial role in maintaining the quality of the extruded plates. Features to look for include:

- Three-Roller Calender: This system compresses and smooths the extruded material to achieve the desired thickness and surface finish.

- Efficient Cooling Techniques: Rapid cooling systems that prevent warping or deformation during solidification.

2.4 Automation and Control Systems

Modern production lines should incorporate advanced automation technologies, including:

- Real-Time Monitoring: Systems that allow operators to monitor and adjust parameters such as temperature, pressure, and speed in real-time.

- User-Friendly Interfaces: HMI (Human-Machine Interface) systems that facilitate easy operation and parameter adjustments.

2.5 Versatility in Applications

A good PP thick plate extrusion line should be adaptable to various applications, such as:

- Chemical Industry: For manufacturing tanks and containers due to their chemical resistance.

- Food Industry: Safe for food contact applications thanks to non-toxic properties.

- Construction Materials: Used in structural applications where lightweight yet strong materials are required.

3. Benefits of Investing in a Quality Production Line

Investing in a high-quality PP thick plate extrusion production line offers numerous advantages:

- Cost-Effectiveness: Efficient processes reduce waste and operational costs.

- Customization Options: Ability to incorporate additives, colorants, and fillers during production allows for tailored solutions.

- Consistent Quality: Advanced automation ensures uniform quality across batches.

4. Challenges in PP Thick Plate Production

Despite its advantages, there are challenges associated with PP thick plate production:

- Material Variability: Fluctuations in raw material quality can affect final product consistency.

- Equipment Maintenance: Regular maintenance is necessary to avoid downtime and ensure optimal performance.

5. Future Trends in Extrusion Technology

The future of PP thick plate extrusion technology looks promising with trends such as:

- Sustainability Initiatives: Increased focus on recycling and using eco-friendly materials in production processes.

- Smart Manufacturing Technologies: Integration of IoT (Internet of Things) for enhanced monitoring and predictive maintenance capabilities.

Conclusion

Investing in a high-quality PP thick plate extrusion production line is essential for manufacturers looking to meet growing market demands while maintaining efficiency and product quality. By focusing on key features such as high-efficiency extruders, precision thickness control, advanced cooling systems, automation, and versatility, companies can enhance their production capabilities significantly.

FAQ

1. What materials can be processed using a PP thick plate extrusion line?

PP thick plate extrusion lines primarily process polypropylene (PP), but they can also handle materials like polyethylene (PE), ABS, and PVC depending on the equipment specifications.

2. What thickness range can be achieved with PP thick plates?

Typically, PP thick plates can be produced with thicknesses ranging from 3 mm to 30 mm, allowing flexibility for various applications.

3. How does recycling work in the extrusion process?

Recycling involves reintroducing scrap material back into the extrusion process, which minimizes waste and reduces overall production costs while maintaining product quality.

4. What industries benefit from using PP thick plates?

Industries such as packaging, automotive, construction, food processing, and environmental protection significantly benefit from using PP thick plates due to their durability and versatility.

5. Are there any environmental advantages to using PP materials?

Yes, polypropylene is recyclable and often produced with energy-efficient processes that lower emissions compared to other materials like PVC or polystyrene.

Citations:

[1] https://www.jwellmachine.com/pp-pe-abs-pvc-thick-plate-extrusion-line/

[2] https://www.jwellmachine.com/pp-pe-pom-board-extrusion-line/

[3] https://www.yjing-extrusion.com/what-are-the-key-benefits-of-pp-thick-plate-extrusion-production-lines.html

[4] https://jwell.co/jwell-product/pp-pe-abs-pvc-thick-sheet-extrusion-line/

[5] https://www.youtube.com/watch?v=OcbMvIo7Q14

[6] https://www.jwellmachine.com/pp-ps-evoh-sheet-extrusion-line/

[7] https://www.jwellfactory.com/news/thick-plate-extrusion-line-72532175.html

[8] https://www.jwellextrusion.com/Plastic-plate--sheet-extrusion-line/pp-pe-abs-pvc-thick-plate-extrusion-line

[9] https://plastic-extrusionmachines.com/pp-hollow-sheet-extrusion-line/

[10] https://www.jwellextrusions.com/products/pp-hollow-sheet-extrusion-line/

[11] https://www.leadertw.com/Plastic-Sheet-Extrusion-Line/PP-Hollow-Profile-Sheet-Extrusion-Line.html

[12] https://www.youtube.com/watch?v=YSIvHdlircQ

[13] https://www.jwellextrusions.com/products/plate-extrusion/

[14] https://www.sheet-extrusionline.com/sale-11723916-pp-pe-pvc-thick-plate-big-thickness-board-extrusion-line-extruder-production-line.html

[15] https://www.gwellmachine.com/sale-13974340-pp-thick-plate-extrusion-line-pp-board-production-machine-quality-after-sales-service.html

[16] https://jwell.co/jwell-product/pp-pe-abs-pvc-thick-plate-extrusion-line/

[17] https://www.lookingplas.com/product/showProductDetail?id=15475

[18] https://iplasticmachine.com/pp-sheet-extrusion-line/

[19] https://www.jwellextrusions.com/products/pe-sheet-extrusion-line/

[20] https://njjiesida.en.made-in-china.com/product/WmRYvZkClNcV/China-Rigid-Polypropylene-PP-Thick-Plate-Making-Machine-PP-Thick-Board-Extrusion-Line.html

[21] https://superior-machinery.en.made-in-china.com/product/WmcRvQNbHikY/China-PP-PE-ABS-PVC-Thick-Plate-Extrusion-Line.html

[22] https://jiahaomachine.en.made-in-china.com/product/QwztkIFOHrGa/China-PP-PE-Thick-Board-Extrusion-Line.html

[23] https://www.jwellplate.com/solution/pp-pe-pvc-pvdf-thick-board-extrusion-line/

[24] https://www.youtube.com/watch?v=x4oe5j0t2-8

[25] https://trustymachine.en.made-in-china.com/product/vwdfBryULDpH/China-PP-PE-ABS-Thick-Board-Plate-Sheet-Extrusion-Making-Machine-Production-Line.html

[26] https://weiermachine.en.made-in-china.com/product/HKLxVowCrcrh/China-PP-PE-Thick-Plate-Machinery.html

[27] https://www.youtube.com/watch?v=Yh0gBsDGOzQ

[28] https://jwellextrusion.en.made-in-china.com/product/STwrWDOLLqhl/China-Jwell-PP-PE-ABS-PVC-Thick-Plate-Making-Machine-Extruder-Machine.html

[29] https://www.plasticextrusion-machine.com/sale-15413293-thick-plate-hdpe-extrusion-machine-4-25mm-pp-pe-pellets-material.html

[30] https://www.youtube.com/watch?v=Z1COQNbOjSo

[31] https://www.instagram.com/jwellmachinerycpp/p/C-odAYbzh5r/?api=1

[32] https://www.pinterest.com/pin/sheet-plate-jwell-pipe-extrusion-machine-compounding-jwellpp-pe-abs-pvc-pvdf-thick-plate-plastic-engine-buy-plastic-sheet-extrusion-machineplastic-board-mak--967640669926487094/

[33] https://www.youtube.com/watch?v=-VR3M0AN4DA

[34] https://www.instagram.com/jwellmachinerycpp/reel/C3-C4yFshQm/

[35] https://www.youtube.com/watch?v=3ye9q9Kk-gU

[36] https://www.facebook.com/sheetextrusionline/

[37] https://www.youtube.com/watch?v=5BLhX7n06pw

[38] https://www.won-plus.com/blog/extrusion-technology-related-questions-and-answers_b40

[39] https://jwellmachine.en.made-in-china.com/product/iZAfTBtHspaS/China-Jwell-Plastic-PP-PE-ABS-PVC-Thick-Plate-Extrusion-Line.html

[40] https://www.jwellmachine.com/pp-pe-pom-board-extrusion-line/

[41] https://www.reddit.com/r/plastic/comments/189bv0k/pp_sheet_extrusion_cooling_roll_problem/

[42] https://jwellmachine.en.made-in-china.com/product/iZSGjoKEnTAq/China-Jwell-PP-Thick-Plate-Extruder-Plastic-Production-Sheet-Extrusion-Machine.html

[43] https://www.reddit.com/r/InjectionMolding/comments/13n3d6x/seeking_information_polypropylene_sheet_extrusion/

[44] https://www.lookingplas.com/product/showProductDetail?id=15472

[45] https://www.jwellextrusion.com/Plastic-plate--sheet-extrusion-line/pp-pe-abs-pvc-thick-plate-extrusion-line

[46] https://www.yjing-extrusion.com/why-choose-a-pe-thick-plate-extrusion-production-line-for-your-business.html

[47] https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/extrusion-issue/

[48] https://www.gwellplastic.com/pp-thick-plate-extrusion-line-9314033.html

[49] https://jwellmachinery.en.made-in-china.com/product/IyjxOTNEEeWg/China-Jwell-PE-PP-2000mm-Thick-Plate-Extrusion-Line-Production-Line-Extrusion-Line-Extruder-Machine.html

[50] https://www.jwellmachine.com/pp-pe-abs-pvc-thick-plate-extrusion-line/

[51] https://www.jwellmachine.com/plate-extrusion-line/

[52] https://www.okorder.com/p/pe-pp-plastic-thick-plates-sheets-extruded-production-line-sheet-board-extrusion-line-sheet-board-making-machine_559299.html

[53] https://www.albis.com/dam/jcr:9a824d2f-bfef-43fc-aff0-347e3c649310/2018-01%20Guide%20to%20PE_PP%20%20Polyolefin%20Sheet%20Extrusion.pdf