Content Menu

● Understanding Aluminum Extrusions

● Key Features of the 80/20 Aluminum Extrusion Catalog

>> Comprehensive Product Range

>> Detailed Specifications

>> Application Examples

>> Custom Solutions

>> User-Friendly Design

>> Sustainability

>> Support and Resources

● Applications of 80/20 Aluminum Extrusions

● Videos Demonstrating 80/20 Aluminum Extrusions

● Benefits of Using 80/20 Aluminum Extrusions

>> Lightweight and Strong

>> Corrosion Resistance

>> Modular Design

>> Cost-Effective Solutions

>> Aesthetic Appeal

● Design Considerations

>> Load Requirements

>> Assembly Techniques

>> Compatibility of Components

>> Future Expansion

● Conclusion

● Frequently Asked Questions

>> 1.What materials are used in 80/20 aluminum extrusions?

>> 2.Can I customize my order from the 80/20 catalog?

>> 3.What industries commonly use 80/20 aluminum extrusions?

>> 4.Are there resources available for designing with 80/20 aluminum extrusions?

>> 5.How do I ensure the right load capacity for my aluminum structure?

Understanding Aluminum Extrusions

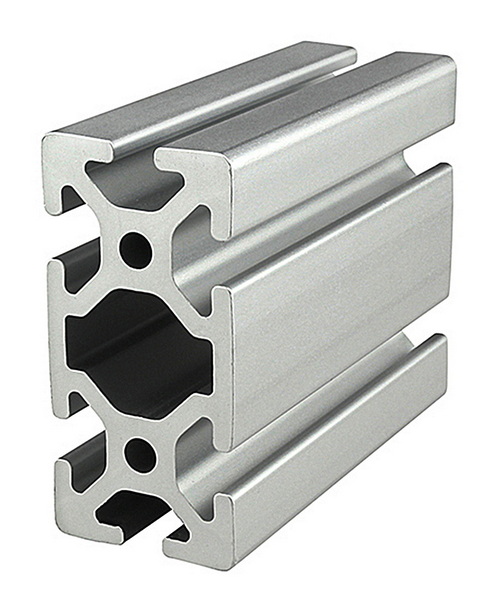

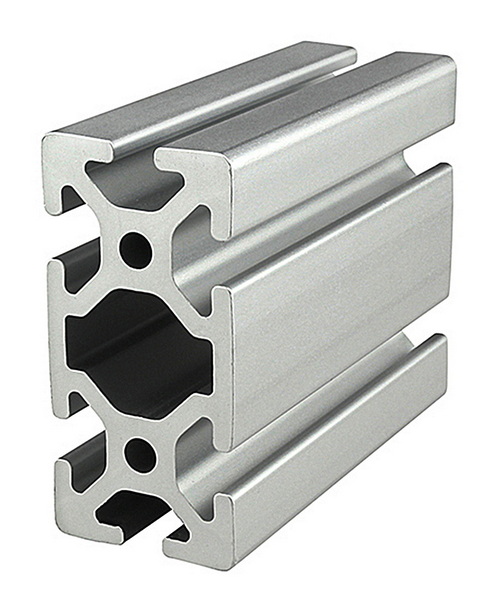

Aluminum extrusions are created by forcing aluminum alloy through a die to produce a specific shape. This process allows for the creation of complex profiles that can be used in a variety of applications. The versatility of aluminum makes it an ideal material for structural components, as it is lightweight, strong, and resistant to corrosion. The 80/20 aluminum extrusion system is particularly popular due to its modular design, which allows for easy assembly and customization.

Key Features of the 80/20 Aluminum Extrusion Catalog

Comprehensive Product Range

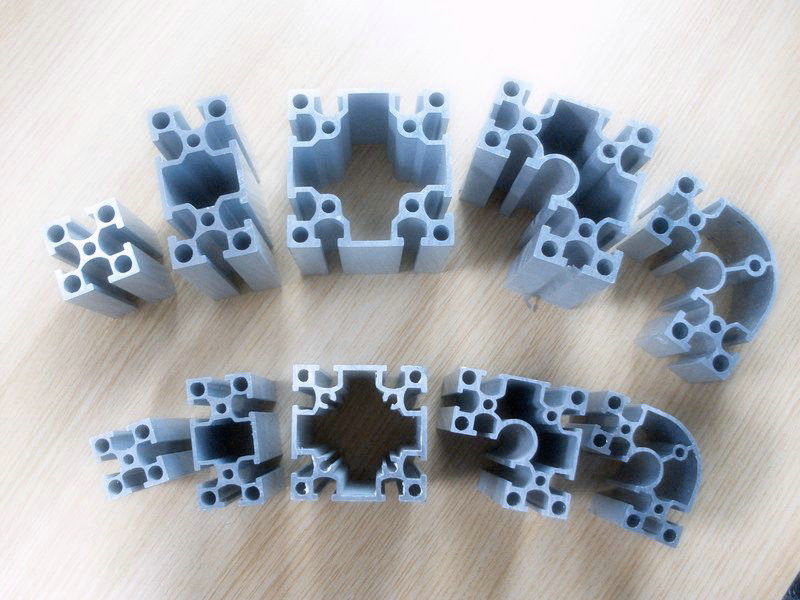

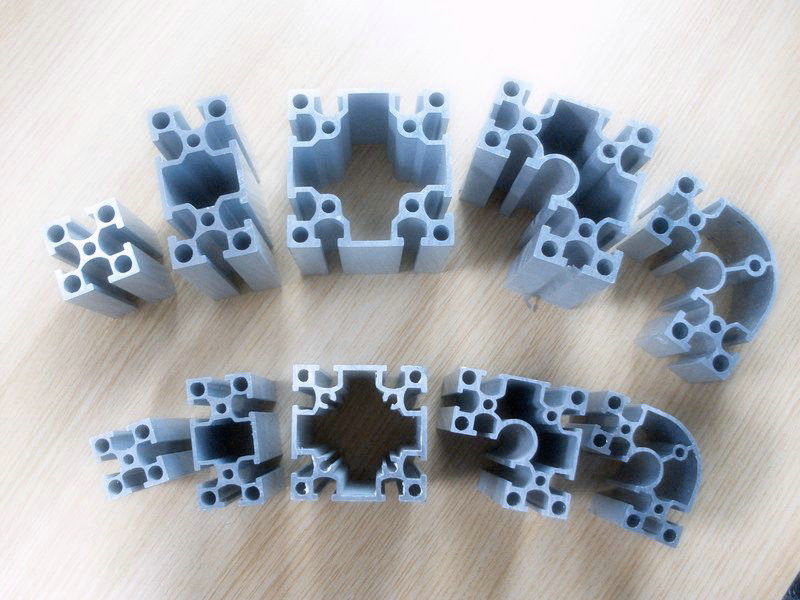

The latest 80/20 aluminum extrusion catalog features an extensive range of products, including:

- T-Slot Profiles: These profiles come in various sizes and shapes, allowing for flexibility in design. The T-slot design enables easy attachment of accessories and components, making it simple to create custom structures.

- Connectors and Fasteners: The catalog includes a variety of connectors, brackets, and fasteners that facilitate the assembly of aluminum extrusions. These components are designed to provide strong connections while maintaining the modularity of the system.

- Accessories: A wide range of accessories, such as end caps, hinges, and wheels, are available to enhance the functionality of the aluminum structures. These accessories allow users to customize their projects further.

Detailed Specifications

Each product in the catalog is accompanied by detailed specifications, including dimensions, weight, and load capacity. This information is crucial for engineers and designers who need to ensure that their designs meet specific requirements. The catalog also provides information on compatible components, making it easier to select the right parts for a project.

Application Examples

The 80/20 aluminum extrusion catalog features numerous application examples that showcase the versatility of the system. These examples include:

- Workstations: Custom workstations can be designed using aluminum extrusions, providing a sturdy and adjustable workspace for various tasks.

- Machine Guards: Aluminum extrusions can be used to create machine guards that protect operators while allowing for easy access to machinery.

- Display Stands: Retailers can use aluminum extrusions to create attractive and functional display stands for products.

Custom Solutions

One of the standout features of the 80/20 aluminum extrusion catalog is the ability to create custom solutions. Users can design their own structures by selecting the appropriate profiles, connectors, and accessories. The modular nature of the system allows for easy reconfiguration, making it ideal for projects that may evolve over time.

User-Friendly Design

The catalog is designed with user-friendliness in mind. It includes clear images and diagrams that help users visualize how to assemble components. Additionally, the layout is intuitive, making it easy to navigate and find the necessary products.

Sustainability

80/20 is committed to sustainability, and their aluminum extrusions are made from recycled materials. This commitment to eco-friendly practices is an important consideration for many businesses and individuals looking to reduce their environmental impact.

Support and Resources

The catalog also provides access to a wealth of resources, including design guides, assembly instructions, and customer support. This support is invaluable for users who may be new to aluminum extrusions or who need assistance with their projects.

Applications of 80/20 Aluminum Extrusions

The versatility of 80/20 aluminum extrusions makes them suitable for a wide range of applications across various industries. Some common applications include:

- Manufacturing: Aluminum extrusions are used to create machine frames, conveyor systems, and workstations in manufacturing environments.

- Automotive: The automotive industry utilizes aluminum extrusions for lightweight structural components, improving fuel efficiency and performance.

- Aerospace: In aerospace applications, aluminum extrusions are used for structural components that require high strength-to-weight ratios.

- Robotics: The modular nature of aluminum extrusions makes them ideal for building robotic structures and frames.

- Furniture: Custom furniture designs can be created using aluminum extrusions, providing a modern and sleek aesthetic.

Videos Demonstrating 80/20 Aluminum Extrusions

To further illustrate the capabilities of 80/20 aluminum extrusions, here are some informative videos that showcase their features and applications:

1. Introduction to 80/20 Aluminum Extrusions

This video provides an overview of the 80/20 aluminum extrusion system, highlighting its modular design and versatility.

2. Building a Custom Workstation

Watch as a custom workstation is built using 80/20 aluminum extrusions, demonstrating the ease of assembly and customization.

3. Innovative Applications of Aluminum Extrusions

This video showcases various innovative applications of aluminum extrusions in different industries.

4. Designing with 80/20

Learn how to design with 80/20 aluminum extrusions, including tips for selecting the right components for your project.

5. Customer Success Stories

Hear from customers who have successfully implemented 80/20 aluminum extrusions in their projects.

Benefits of Using 80/20 Aluminum Extrusions

Using 80/20 aluminum extrusions offers numerous benefits that make them a preferred choice for many applications:

Lightweight and Strong

Aluminum is known for its excellent strength-to-weight ratio. This means that structures built with 80/20 aluminum extrusions can be both lightweight and strong, making them ideal for applications where weight is a concern, such as in aerospace and automotive industries.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer that helps prevent corrosion. This property makes aluminum extrusions suitable for outdoor applications and environments where exposure to moisture and chemicals is a concern.

Modular Design

The modular design of 80/20 aluminum extrusions allows for easy assembly and disassembly. This feature is particularly beneficial for projects that may require reconfiguration or expansion over time. Users can easily add or remove components without the need for specialized tools.

Cost-Effective Solutions

While the initial investment in aluminum extrusions may be higher than some other materials, the long-term cost savings can be significant. The durability and low maintenance requirements of aluminum structures can lead to reduced operational costs over time.

Aesthetic Appeal

Aluminum extrusions offer a modern and sleek appearance, making them an attractive choice for furniture and display applications. The ability to anodize or powder coat aluminum also allows for customization in color and finish.

Design Considerations

When designing with 80/20 aluminum extrusions, there are several key considerations to keep in mind:

Load Requirements

Understanding the load requirements of your project is crucial. The catalog provides detailed specifications for each profile, including load capacity. It is essential to select profiles that can safely support the intended loads.

Assembly Techniques

Familiarizing yourself with the various assembly techniques is important for ensuring a strong and stable structure. The catalog includes assembly instructions and tips for using connectors and fasteners effectively.

Compatibility of Components

When selecting components, it is important to ensure compatibility between profiles, connectors, and accessories. The catalog provides information on which components work well together, helping to streamline the design process.

Future Expansion

Consider the potential for future expansion when designing your structure. The modular nature of 80/20 aluminum extrusions allows for easy modifications, so planning for future needs can save time and resources down the line.

Conclusion

The latest 80/20 aluminum extrusion catalog is an invaluable resource for anyone looking to utilize aluminum extrusions in their projects. With its comprehensive product range, detailed specifications, and user-friendly design, the catalog empowers users to create custom solutions that meet their specific needs. Whether you are an engineer, designer, or DIY enthusiast, the 80/20 aluminum extrusion catalog offers the tools and resources necessary to bring your ideas to life. The combination of lightweight strength, corrosion resistance, and modular design makes 80/20 aluminum extrusions a top choice for a wide range of applications across various industries.

Frequently Asked Questions

1.What materials are used in 80/20 aluminum extrusions?

80/20 aluminum extrusions are made from high-quality aluminum alloys, which provide strength, durability, and resistance to corrosion.

2.Can I customize my order from the 80/20 catalog?

Yes, the 80/20 catalog allows for customization, enabling users to select specific profiles, connectors, and accessories to create tailored solutions.

3.What industries commonly use 80/20 aluminum extrusions?

Industries such as manufacturing, automotive, aerospace, robotics, and furniture design frequently utilize 80/20 aluminum extrusions.

4.Are there resources available for designing with 80/20 aluminum extrusions?

Yes, the catalog provides design guides, assembly instructions, and customer support to assist users in their projects.

5.How do I ensure the right load capacity for my aluminum structure?

The catalog includes detailed specifications for each product, including load capacity, which helps users select the appropriate components for their designs.