Content Menu

● Introduction to Plastic Pipe Extrusion Machinery

>> Components of Plastic Pipe Extrusion Machinery

● Operation Process of Plastic Pipe Extrusion Machinery

● Applications of Plastic Pipe Extrusion Machinery

● Key Features of Quality Plastic Pipe Extrusion Machinery

● Advanced Technologies in Plastic Pipe Extrusion Machinery

● Maintenance and Troubleshooting of Plastic Pipe Extrusion Machinery

● Environmental Impact and Sustainability

● Future Developments in Plastic Pipe Extrusion Machinery

● Conclusion

● FAQ

>> 1. What are the main types of plastic pipe extrusion machines?

>> 2. How does the plastic extrusion process work?

>> 3. What are the advantages of using plastic pipes over traditional materials?

>> 4. How can I improve the quality of plastic pipes produced by my extrusion machine?

>> 5. What factors should I consider when selecting a plastic pipe extrusion machine?

● Citations:

Plastic pipe extrusion machinery is a crucial component in the manufacturing of plastic pipes, which are widely used in various industries such as construction, agriculture, and utilities. These machines enable the production of pipes with consistent quality and dimensions, offering advantages such as corrosion resistance, lighter weight, and easier installation compared to traditional materials. In this article, we will delve into the key features of plastic pipe extrusion machinery, exploring its components, operation process, and applications.

Introduction to Plastic Pipe Extrusion Machinery

Plastic pipe extrusion machinery operates by melting raw plastic materials and shaping them into continuous pipe profiles through a die. The process involves several stages, each vital for producing durable and high-performance pipes.

Components of Plastic Pipe Extrusion Machinery

A typical plastic pipe extrusion line consists of several critical components:

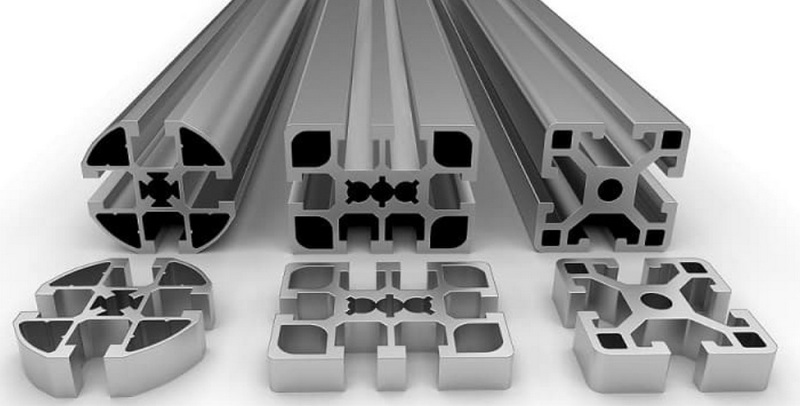

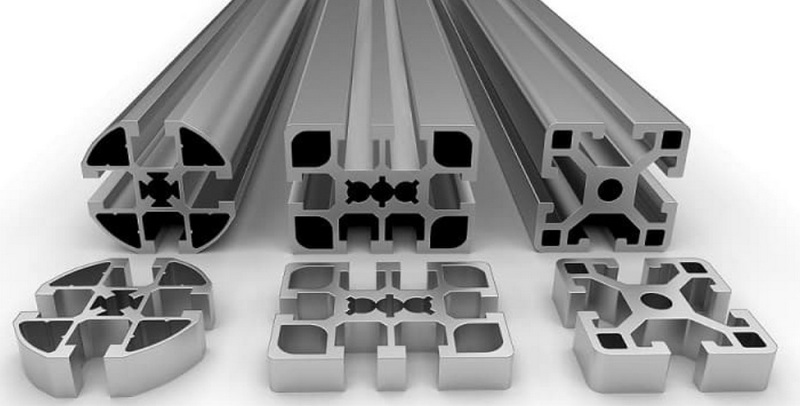

- Extruder: The heart of the machine, responsible for melting and preparing raw materials for shaping. It can be either a single-screw or twin-screw extruder, with twin-screw offering better mixing capabilities for complex applications.

- Die Head: Shapes the molten plastic into the desired pipe profile. Its design determines the shape and size of the final pipe.

- Cooling System: Ensures the pipe solidifies into its final shape without deformation. Common cooling methods include water baths or air blowers.

- Haul-Off Unit: Pulls the pipe from the die at a controlled speed, crucial for maintaining pipe dimensions and preventing deformation.

- Cutter or Winder: Cuts the pipes into desired lengths or winds them for storage.

Operation Process of Plastic Pipe Extrusion Machinery

The operation process involves several key stages:

1. Feeding: Raw plastic pellets or granules are fed into the extruder's hopper.

2. Melting: The plastic is melted by heat and friction within the barrel.

3. Shaping: The molten material passes through the die to form the pipe shape.

4. Cooling: The pipe is cooled using water or air to maintain its shape.

5. Sizing and Calibration: Ensures the pipe meets the required dimensions and specifications.

6. Cutting: The pipe is cut into specified lengths.

Applications of Plastic Pipe Extrusion Machinery

Plastic pipes produced by these machines are used in various applications:

- Water and Sewer Mains: HDPE pipes are commonly used due to their durability and resistance to corrosion.

- Gas Mains: PE pipes are preferred for gas distribution due to their safety and reliability.

- Irrigation Systems: Plastic pipes are lightweight and easy to install, making them ideal for agricultural use.

- Electrical and Communications Conduit: Used for protecting cables and wires.

Key Features of Quality Plastic Pipe Extrusion Machinery

To ensure efficient production and high-quality pipes, the machinery should have the following features:

- Single or Twin Screw Extruder: Twin-screw extruders offer better mixing capabilities, ideal for complex materials.

- Quality Control System: Essential for regulating machine operation and ensuring consistent product quality.

- Material Feeding System: A direct drive system ensures consistent material feeding, enhancing product strength and quality.

- Die and Head Assembly: Determines the shape and properties of the pipe.

Advanced Technologies in Plastic Pipe Extrusion Machinery

Recent advancements include the integration of automation and IoT technologies, allowing for real-time monitoring and adjustments to improve efficiency and reduce waste. Additionally, the use of advanced materials like bioplastics and nanocomposites is becoming more prevalent, offering enhanced sustainability and performance.

Maintenance and Troubleshooting of Plastic Pipe Extrusion Machinery

Regular maintenance is crucial to prevent common faults such as rough outer surfaces, uneven wall thickness, and insufficient roundness. Solutions include adjusting process temperatures, checking cooling water circuits, and ensuring proper raw material quality. Regular cleaning of the extruder and die is also essential to prevent material buildup and contamination.

Environmental Impact and Sustainability

Plastic pipe extrusion machinery contributes to sustainability by producing pipes that are durable and resistant to corrosion, reducing the need for frequent replacements and minimizing environmental impact. However, the industry is also shifting towards more sustainable practices, such as using recycled materials and reducing energy consumption during production.

Future Developments in Plastic Pipe Extrusion Machinery

Future developments are expected to focus on enhancing efficiency, reducing environmental impact, and integrating advanced materials. The use of AI and machine learning could optimize production processes further, while advancements in material science could lead to pipes with improved properties and longer lifespans.

Conclusion

Plastic pipe extrusion machinery plays a vital role in producing high-quality pipes for various applications. Understanding its components, operation process, and key features is essential for optimizing production efficiency and product quality. By selecting the right machinery and maintaining it properly, manufacturers can ensure consistent output and meet the growing demand for plastic pipes.

FAQ

1. What are the main types of plastic pipe extrusion machines?

Plastic pipe extrusion machines primarily include single-screw, twin-screw, co-extrusion, and continuous extrusion machines. Each type is suited for different materials and applications.

2. How does the plastic extrusion process work?

The process involves feeding raw plastic into an extruder, melting it, shaping it through a die, cooling it to solidify, sizing it to specifications, and cutting it to desired lengths.

3. What are the advantages of using plastic pipes over traditional materials?

Plastic pipes offer advantages such as corrosion resistance, lighter weight, easier installation, and long service life compared to traditional materials like metal or concrete.

4. How can I improve the quality of plastic pipes produced by my extrusion machine?

Quality can be improved by using high-quality raw materials, optimizing the extrusion process parameters, and implementing strict quality control measures.

5. What factors should I consider when selecting a plastic pipe extrusion machine?

Considerations include production capacity, material compatibility, machine complexity, cost and ROI, and after-sales service and support.

Citations:

[1] https://www.jwellextrusions.com/the-characteristics-of-pe-pipe-extrusion-line.html

[2] https://www.caisumachinery.com/what-is-a-pipe-extrusion-machine-a-complete-guide/

[3] https://www.adremac.com/the-basic-principles-of-pipe-extrusion-key-components-and-technologies/

[4] https://www.youtube.com/watch?v=Kv9wpOf5iVg

[5] https://plasticextrusiontech.net/capabilities/capabilities-faqs/

[6] https://plastic-extrusionmachines.com/the-basic-principles-of-pipes-extrusion/

[7] https://www.caisumachinery.com/plastic-pipe-extrusion-machine-a-comprehensive-guide/

[8] https://www.won-plus.com/blog/extrusion-technology-related-questions-and-answers_b40

[9] https://jieyatwinscrew.com/blog/pvc-pipe-extruder-machine/

[10] https://www.accextrusion.com/news/common-faults-and-solutions-of-plastic-pipe-extrusion-line/

[11] https://www.qiangshengplas.com/news/what-are-the-key-features-of-quality-plastic-pipe-extrusion-lines/

[12] https://www.plastikcity.co.uk/blog/what-is-plastic-extrusion/

[13] https://jydjx.com/components-of-pipe-extrusion-lines/

[14] https://jfextruder.com/what-is-a-plastic-extruder-machine/

[15] https://jwellmachinery.en.made-in-china.com/product/nBuJIMplsbYH/China-Plastic-Pipe-Extrusion-Machine-Machines.html

[16] https://www.accextrusion.com/news/the-design-and-components-of-plastic-pipe-extrusion-line/

[17] https://www.adremac.com/complete-guide-to-pipe-extrusion-machinery-equipment-and-advanced-cutting-solutions/

[18] https://windsormachines.com/upvc-pipe-manufacturing-plant/

[19] https://www.hmel.in/assets/pdf/technical_guide_to_pipe_extrusion_process_&_polysure_products-final_small.pdf

[20] https://drts.com/what-to-look-for-extruder-machine/

[21] https://jieyatwinscrew.com/blog/pvc-extruder-machine-everything-you-need-to-know/

[22] https://www.beierextrusion.com/what-are-the-components-of-pvc-pipe-extrusion-line/