Content Menu

● Introduction to Jay Extrusion Machinery

>> Mission and Vision

● Key Features of Jay Extrusion Machinery

>> Product Range

>>> Customized Solutions

>> Applications

● Innovative Technology

● Customer Support

● Global Impact

● Conclusion

● Frequently Asked Questions

>> 1. What types of polymers does Jay Extrusion Machinery handle?

>> 2. What are the main product series offered by Jay Extrusion Machinery?

>> 3. What kind of customer support does Jay Extrusion Machinery provide?

>> 4. What are some of the key applications of Jay Extrusion Machinery's technology?

>> 5. What is Jay Extrusion Machinery's mission?

● Citations:

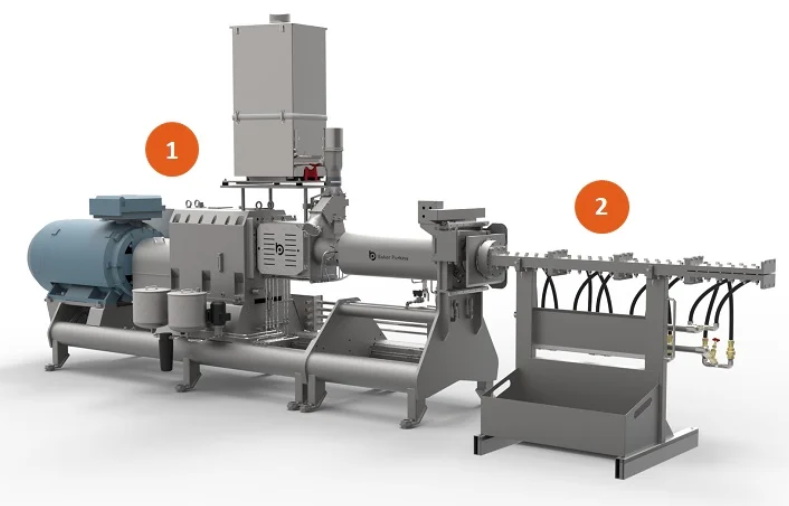

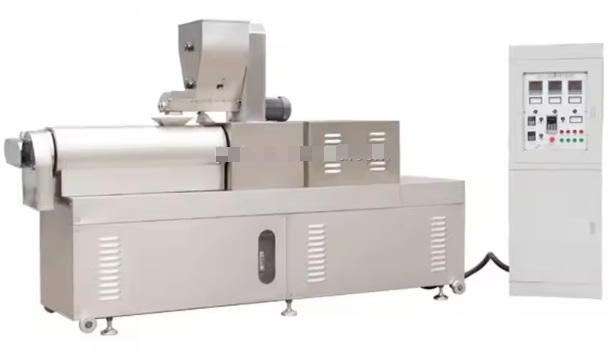

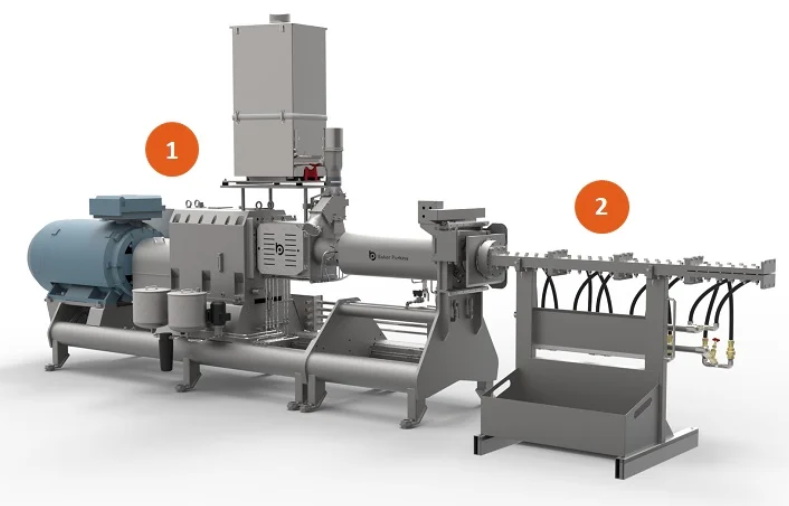

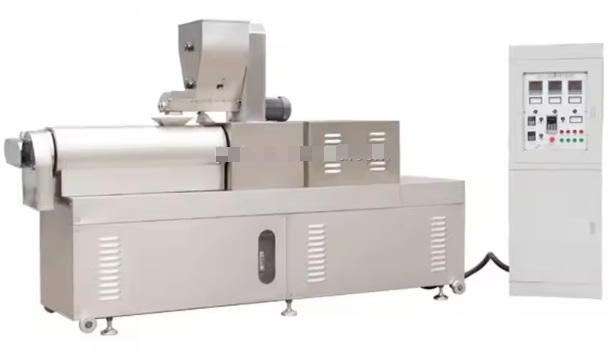

Jay Extrusion Machinery has emerged as a leading manufacturer and exporter in the extrusion machinery industry, specializing in twin screw extruder lines for compounding and recycling various polymers. This article will delve into the key features of Jay Extrusion Machinery, highlighting its innovative solutions, product range, and commitment to customer satisfaction.

Introduction to Jay Extrusion Machinery

Established in 2011, Jay Extrusion Machinery has set high standards of quality and innovation in the extrusion machinery sector. The company is renowned for its expertise in handling a wide range of polymers, including polypropylene, high-density materials, and engineering thermoplastics such as polyamide, polycarbonate, ABS, PMMA, HIPS, and GPPS[1].

Mission and Vision

Jay Extrusion Machinery aims to revolutionize industries worldwide through innovation, reliability, and unmatched quality. Their mission is to make a global impact with cutting-edge extrusion machinery solutions, ensuring operational efficiency and precision for diverse client needs[1].

Key Features of Jay Extrusion Machinery

Product Range

Jay Extrusion Machinery offers an extensive range of advanced extrusion machinery, including three main series: JHE, JTE, and JTE-E. Additionally, they provide a comprehensive range of spare parts and auxiliary equipment such as air knives, vibrators, screw shafts & barrels, pelletizers, and more[1].

Customized Solutions

The company provides customized solutions for optimizing manufacturing processes, ensuring that each client's specific needs are met. This includes comprehensive coverage across the entire plant process, from raw material feeding to pelletizing and drying[1].

Applications

Jay Extrusion Machinery's focal applications include:

- Colouring, Alloying, and Mixing: Handling base polymers with fillers and reinforcement materials for Nylon, Derlin, Noril, ABS, PBT, PC, SAN, EVA, PP Filled, Alloying & colouring compounds.

- Masterbatch Production: Creating colour and black masterbatches with Polyamide, LLDPE, ABS, PC, and PET polymers for diverse industrial applications.

- Recycling Technology: Specialized technology for recycling engineering polymers, ensuring homogenous mixing and maintenance of rheological properties.

- Elastomer Alloys: Creating elastomer alloys with varying percentages of thermoplastics and elastomers to meet specific material performance requirements.

- Biodegradable Products: Offering direct extrusion solutions for the production of biodegradable products, catering to eco-friendly manufacturing needs.

- Toner Compounding Systems: Designing and implementing compounding systems for high-quality toners, delicately handling magnetized resins[1].

Innovative Technology

Jay Extrusion Machinery leverages top-tier facilities and skilled professionals to deliver innovative solutions. Their systematic approach ensures operational efficiency and precision, with customization central to meeting diverse client needs.

Customer Support

Jay Extrusion Machinery stands by its customers every step of the way, providing high-quality spare parts and instant resolutions for any machine-related issues. This dedicated support ensures uninterrupted business operations and maximum efficiency[1].

Global Impact

With a mission to go beyond borders, Jay Extrusion Machinery aims to make a global impact with its cutting-edge extrusion machinery solutions. The company is committed to revolutionizing industries worldwide through innovation, reliability, and unmatched quality[1].

Conclusion

Jay Extrusion Machinery is a premier Indian manufacturer and exporter in the extrusion machinery industry, known for its innovative solutions, extensive product range, and commitment to customer satisfaction. With a focus on customization and operational efficiency, Jay Extrusion Machinery continues to set high standards in the industry.

Frequently Asked Questions

1. What types of polymers does Jay Extrusion Machinery handle?

Jay Extrusion Machinery specializes in handling a wide range of polymers, including polypropylene, high-density materials, and engineering thermoplastics such as polyamide, polycarbonate, ABS, PMMA, HIPS, and GPPS[1].

2. What are the main product series offered by Jay Extrusion Machinery?

Jay Extrusion Machinery offers three main product series: JHE, JTE, and JTE-E, along with a comprehensive range of spare parts and auxiliary equipment[1].

3. What kind of customer support does Jay Extrusion Machinery provide?

Jay Extrusion Machinery provides dedicated customer support, including high-quality spare parts and instant resolutions for any machine-related issues to ensure uninterrupted business operations[1].

4. What are some of the key applications of Jay Extrusion Machinery's technology?

Key applications include colouring, alloying, and mixing of polymers, masterbatch production, recycling technology, elastomer alloys, biodegradable products, and toner compounding systems[1].

5. What is Jay Extrusion Machinery's mission?

Jay Extrusion Machinery aims to revolutionize industries worldwide through innovation, reliability, and unmatched quality, making a global impact with its cutting-edge extrusion machinery solutions[1].

Citations:

[1] https://www.jayextruder.com

[2] http://www.neotronics.com.tw/2013newweb/4_extruder/Machine_Single_screw_extruder.html

[3] https://www.jayjalaramext.com

[4] https://www.jayextruder.com/about-us.php

[5] https://www.jayextruder.com/jte-series.html

[6] https://www.youtube.com/watch?v=KFkzRZHEpLw

[7] https://www.indiamart.com/proddetail/pelletizer-2855573959573.html

[8] https://www.importgenius.com/india/importers/jay-extrusion-machinery

[9] https://in.linkedin.com/in/sanjay-vashi-920a50b2

[10] https://www.indiamart.com/company/162130792/

[11] https://www.indiamart.com/proddetail/twin-screw-extruder-17992236173.html

[12] https://www.justdial.com/Gandhinagar-Gujarat/Extrusion-Blow-Moulding-Machine-Manufacturers-in-Chhatral-Gidc/nct-10196403

[13] https://www.youtube.com/watch?v=7cVQ3Ohmktw

[14] https://dir.indiamart.com/impcat/vermicelli-extruder-machine.html?biz=30

[15] https://anrweb.vt.gov/PubDocs/DEC/Air/Permits/1440.doc

[16] https://www.justdial.com/Vadodara/Puff-Extruder-Machine-Manufacturers/nct-11638870

[17] https://www.jayextruder.com/gallery.php

[18] https://www.youtube.com/watch?v=lFaVpudiHAM

[19] https://www.youtube.com/watch?v=tkU4uSgvEOI

[20] https://www.linkedin.com/company/jay-extrusion-machinery

[21] https://www.youtube.com/watch?v=HLax1ZxsguM

[22] https://modernplastics.tv/an-exclusive-interview-with-mr-sanjay-vashi-director-jay-extrusion-machinery-modern-plastics-tv/

[23] https://www.exportersindia.com/jay-extrusion/about-us.htm

[24] https://www.wattagnet.com/home/article/15527065/extruder-maintenance-4-steps-to-optimize-reduce-costs-wattagnet

[25] https://www.jayextruder.com/contact.html

[26] https://www.jayequipment.com/faq.php

[27] https://www.justdial.com/jdmart/Jamnagar/Jay-Extrusion-Dared-Dared/0288PX288-X288-190612191849-P3E9_BZDET/catalogu