Content Menu

● Table of Contents

● Introduction to Indirect Aluminum Extrusion

● How Indirect Aluminum Extrusion Works

● Key Features of an Indirect Aluminum Extrusion Press

>> 1. Reduced Friction

>> 2. Consistent Force Application

>> 3. Improved Material Flow

>> 4. Lower Operating Temperatures

>> 5. Capability to Process Harder Alloys

>> 6. Compact Design

● Benefits of Using Indirect Aluminum Extrusion Presses

● Applications in Various Industries

● Comparison: Direct vs. Indirect Aluminum Extrusion

● Challenges and Limitations

● Conclusion

● FAQs

>> 1. What is an indirect aluminum extrusion press?

>> 2. How does indirect extrusion differ from direct extrusion?

>> 3. What are the advantages of using an indirect press?

>> 4. Which industries benefit most from indirect extrusion?

>> 5. Can indirect presses handle complex shapes?

● Citations:

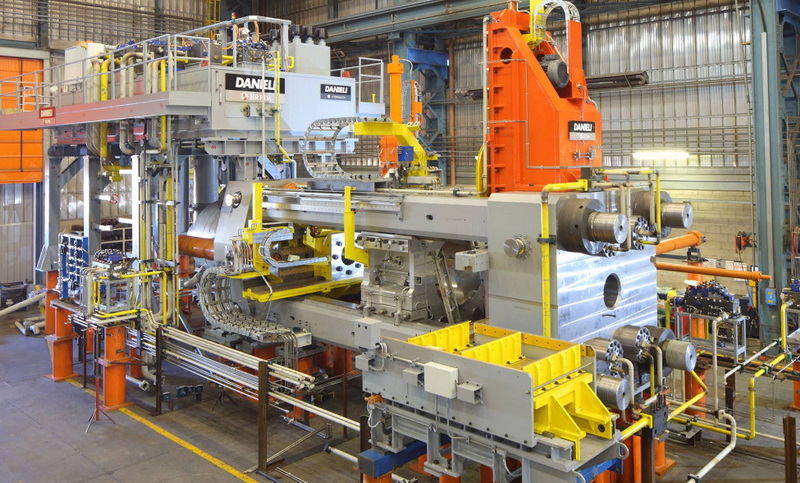

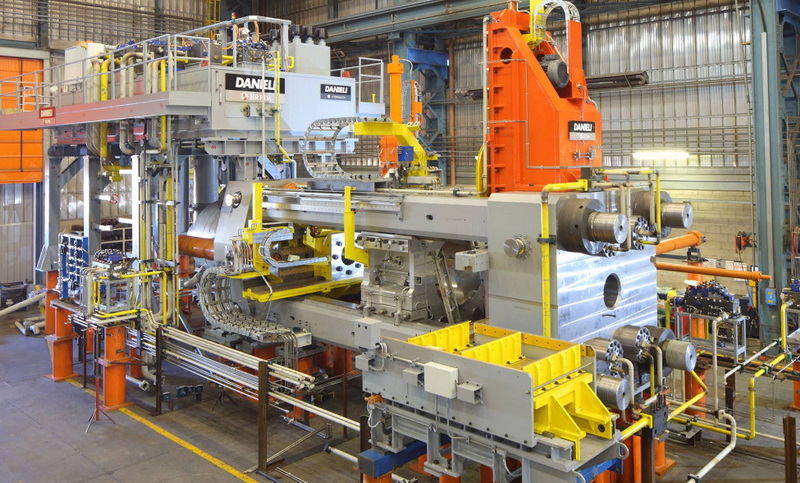

Aluminum extrusion is a transformative process used to create components with specific cross-sectional profiles, offering unmatched versatility and strength. Among the two main types of extrusion processes—direct and indirect—indirect aluminum extrusion presses stand out due to their unique advantages. This article delves into the key features, benefits, and applications of indirect aluminum extrusion presses.

Table of Contents

1. Introduction to Indirect Aluminum Extrusion

2. How Indirect Aluminum Extrusion Works

3. Key Features of an Indirect Aluminum Extrusion Press

4. Benefits of Using Indirect Aluminum Extrusion Presses

5. Applications in Various Industries

6. Comparison: Direct vs. Indirect Aluminum Extrusion

7. Challenges and Limitations

8. Conclusion

9. FAQs

Introduction to Indirect Aluminum Extrusion

Indirect aluminum extrusion, also known as backward extrusion, is a specialized process where the billet remains stationary while the die moves against it. This method significantly reduces friction between the billet and container walls, resulting in better material flow and consistent quality.

How Indirect Aluminum Extrusion Works

In an indirect extrusion press:

- The billet (a cylindrical block of aluminum) is placed stationary inside a container.

- A hollow ram holds the die, which moves relative to the billet.

- The aluminum is forced through the die opening, forming the desired shape.

This process eliminates most frictional forces that are present in direct extrusion, leading to more efficient energy use and better control over the extrusion process [3][5][9].

Key Features of an Indirect Aluminum Extrusion Press

1. Reduced Friction

The absence of friction between the billet and container walls ensures a smoother extrusion process with lower energy consumption [5][6].

2. Consistent Force Application

Since friction is minimized, the force required for extrusion remains nearly constant throughout the process [6][11].

3. Improved Material Flow

The uniform pressure distribution allows for better material flow, improving grain structure and mechanical properties [3][10].

4. Lower Operating Temperatures

Indirect presses operate at lower temperatures due to reduced friction, which enhances surface finish and dimensional accuracy [3][5].

5. Capability to Process Harder Alloys

Indirect extrusion presses are ideal for high-strength aluminum alloys like AA2xxx and AA7xxx, which require precise handling [1][7].

6. Compact Design

Many indirect presses feature compact designs that allow for smaller cross-sections and intricate profiles [7].

Benefits of Using Indirect Aluminum Extrusion Presses

- Energy Efficiency: Lower friction reduces energy consumption during operation [6].

- Enhanced Product Quality: Consistent temperature control improves surface finish and mechanical properties [10].

- Higher Productivity: Faster processing speeds due to reduced heat generation [3].

- Tight Tolerances: Achieves precise dimensions, making it suitable for complex shapes [7].

- Longer Tool Life: Reduced wear on dies and containers extends equipment lifespan [6].

Applications in Various Industries

Indirect aluminum extrusion presses are used across numerous sectors:

- Automotive: Lightweight components like frames and panels.

- Aerospace: High-strength parts for structural integrity.

- Construction: Window frames, curtain walls, and other architectural elements.

- Electronics: Heat sinks and enclosures for electronic devices.

- Consumer Goods: Custom profiles for furniture and appliances.

Comparison: Direct vs. Indirect Aluminum Extrusion

| Feature |

Direct Extrusion |

Indirect Extrusion |

| Friction |

High |

Low |

| Energy Consumption |

Higher |

Lower |

| Temperature Control |

Less Precise |

More Precise |

| Product Quality |

Moderate |

High |

| Suitable Alloys |

Common Alloys |

Harder Alloys (e.g., AA2xxx, AA7xxx) |

| Tool Wear |

Higher |

Lower |

Challenges and Limitations

While indirect aluminum extrusion offers numerous advantages, it also has some limitations:

1. Size Restrictions: Limited by the length of the hollow ram stem [6].

2. Surface Quality Sensitivity: Impurities in billets can affect surface finish [6].

3. Complexity in Setup: Requires precise alignment of components.

Conclusion

Indirect aluminum extrusion presses represent a sophisticated solution for producing high-quality aluminum profiles with tight tolerances and superior mechanical properties. By minimizing friction and maintaining consistent force application, these presses excel in processing harder alloys while ensuring energy efficiency.

As industries continue to demand lightweight yet durable materials, indirect aluminum extrusion will remain a cornerstone technology.

FAQs

1. What is an indirect aluminum extrusion press?

An indirect aluminum extrusion press is a machine where the die moves against a stationary billet to produce extruded profiles with minimal friction.

2. How does indirect extrusion differ from direct extrusion?

In indirect extrusion, the billet remains stationary while the die moves; in direct extrusion, both the billet and ram move in the same direction.

3. What are the advantages of using an indirect press?

Key advantages include reduced friction, lower operating temperatures, better product quality, and suitability for harder alloys.

4. Which industries benefit most from indirect extrusion?

Industries like automotive, aerospace, construction, electronics, and consumer goods benefit due to their need for lightweight yet strong components.

5. Can indirect presses handle complex shapes?

Yes, they are ideal for intricate profiles requiring tight tolerances due to their consistent force application.

Citations:

[1] https://www.sms-group.com/plants/light-metal-extrusion-presses

[2] https://www.youtube.com/watch?v=Olytr4PEDPs

[3] https://www.impol.com/everything-you-need-to-know-about-aluminum-extrusion/

[4] https://www.hydro.com/profiles/what-are-aluminum-extrusions

[5] https://www.shapesbyhydro.com/en/expert-thoughts/do-you-know-when-to-use-the-indirect-extrusion-process/

[6] https://www.youtube.com/watch?v=x4oq143fZFQ

[7] https://paramountextrusions.com/custom-aluminum-extrusion-capabilities

[8] https://bonnellaluminum.com/tech-info-resources/aluminum-extrusion-process/

[9] https://www.linkedin.com/pulse/aluminum-extrusion-process-grace-gao-1

[10] https://waykenrm.com/blogs/aluminum-extrusion/

[11] https://www.howardprecision.com/what-are-the-differences-between-a-direct-and-indirect-aluminum-extrusion-press/