Content Menu

● Understanding Aluminum Extrusion Milling Machines

● Key Features of High-Quality Aluminum Extrusion Milling Machines

● Technological Advancements in Aluminum Extrusion Milling Machines

● Applications of Aluminum Extrusion Milling Machines

● Maintenance Tips for Aluminum Extrusion Milling Machines

● Future Trends in Aluminum Extrusion Milling Technology

● Conclusion

● FAQ

>> 1. What is an aluminum extrusion milling machine?

>> 2. How does a CNC system improve milling accuracy?

>> 3. Why is cooling important during the milling process?

>> 4. What types of industries use aluminum extrusion milling machines?

>> 5. How does automation benefit aluminum extrusion milling?

● Citations:

Aluminum extrusion milling machines are essential tools in the manufacturing sector, particularly for industries that require precision machining of aluminum profiles. These machines are designed to enhance productivity and ensure high-quality outputs. In this article, we will explore the key features of a high-quality aluminum extrusion milling machine, examining their design, functionality, and technological advancements.

Understanding Aluminum Extrusion Milling Machines

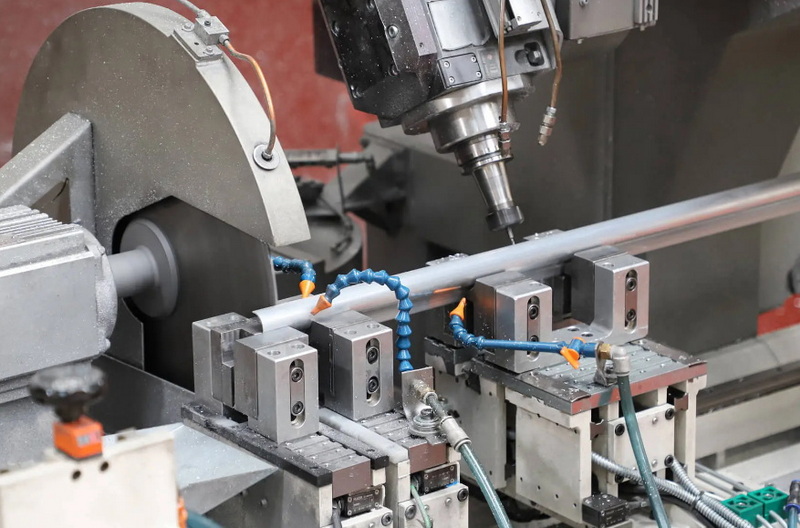

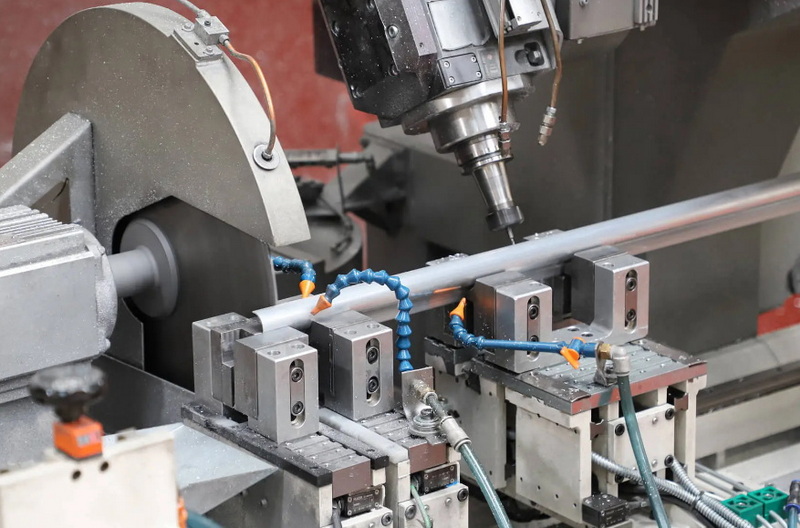

Aluminum extrusion milling machines are specialized equipment used to cut and shape aluminum extrusions. They operate by removing material from the aluminum profile to achieve the desired dimensions and surface finishes. These machines are integral in various applications, including aerospace, automotive, construction, and electronics.

The process of aluminum extrusion itself involves forcing aluminum alloy through a die to create long shapes with a constant cross-section. After extrusion, these profiles often require further machining to meet specific tolerances and surface quality standards. This is where milling comes into play, allowing manufacturers to achieve precise dimensions and intricate designs that are not possible through extrusion alone.

Key Features of High-Quality Aluminum Extrusion Milling Machines

When evaluating aluminum extrusion milling machines, several critical features should be considered:

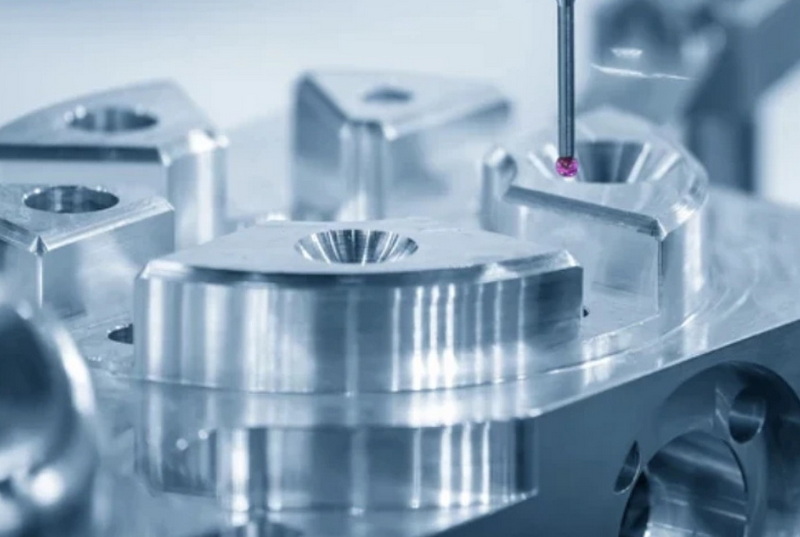

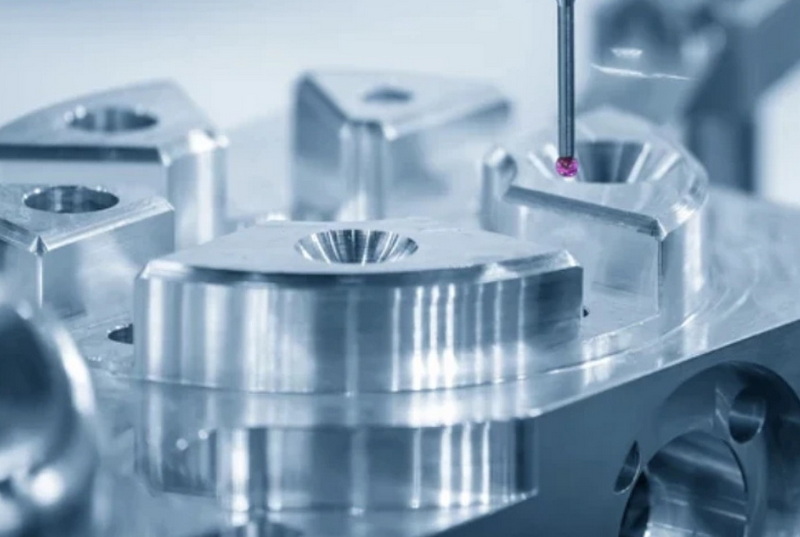

- Precision Engineering: A high-quality machine must offer precise control over cutting dimensions. This is achieved through advanced CNC (Computer Numerical Control) systems that allow for intricate programming and repeatability. The precision of these machines is crucial for applications where tight tolerances are required.

- Robust Construction: The machine's frame should be constructed from durable materials to withstand the rigors of continuous operation. This ensures stability during machining processes, leading to better accuracy. A robust construction minimizes vibrations that can affect the quality of the finished product.

- High Spindle Speed: Effective milling of aluminum requires high spindle speeds. Machines with spindle speeds ranging from 10,000 to 20,000 RPM can efficiently remove material while maintaining surface integrity. High spindle speeds also contribute to shorter cycle times and increased productivity.

- Cooling Systems: Milling aluminum generates heat, which can lead to tool wear and poor surface finishes. High-quality machines incorporate effective cooling systems that utilize lubricants or coolant fluids to maintain optimal operating temperatures. Proper cooling not only extends tool life but also improves the overall quality of the machined surfaces.

- Versatile Tooling Options: A good aluminum extrusion milling machine should accommodate various tooling options to handle different profiles and cutting tasks. This includes end mills, drills, and specialized cutters designed for aluminum. The ability to use different tools allows manufacturers to adapt quickly to changing production needs.

- User-Friendly Interface: Modern machines feature intuitive control panels with touchscreen interfaces that simplify operation and programming. This is crucial for reducing setup times and minimizing errors. User-friendly interfaces also facilitate easier training for new operators.

- Automatic Tool Change: To enhance productivity, many advanced machines include automatic tool changers that allow for quick switching between different tools without manual intervention. This feature is particularly beneficial in high-volume production environments where multiple operations are performed on a single workpiece.

- Safety Features: Safety is paramount in any machining environment. High-quality machines come equipped with safety guards, emergency stop buttons, and other features to protect operators. Additionally, some machines include sensors that detect unsafe conditions and automatically shut down operations.

Technological Advancements in Aluminum Extrusion Milling Machines

Recent innovations have significantly improved the functionality of aluminum extrusion milling machines:

- Integration with CAD/CAM Software: Many modern machines can integrate with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. This allows for seamless design-to-manufacturing workflows, enhancing efficiency by reducing the time between design completion and production initiation.

- Real-Time Monitoring Systems: Advanced milling machines may include sensors that monitor operational parameters in real-time. This data can be used for predictive maintenance, reducing downtime and improving reliability. By analyzing performance metrics, manufacturers can identify potential issues before they lead to machine failures.

- Increased Automation: Automation technologies such as robotic arms can be integrated into milling operations to handle loading and unloading of parts, further enhancing production efficiency. Automated systems can operate continuously without breaks, increasing overall throughput.

- Enhanced Material Handling Systems: Modern milling machines often come equipped with advanced material handling systems that facilitate the movement of heavy aluminum profiles into position for machining. These systems reduce manual labor requirements and improve safety by minimizing the risk of injury during part handling.

Applications of Aluminum Extrusion Milling Machines

Aluminum extrusion milling machines find applications across various industries:

- Aerospace Industry: Precision components are critical in aerospace applications where weight reduction and strength are essential. The ability to produce complex geometries while maintaining strict tolerances makes these machines invaluable in this sector.

- Automotive Manufacturing: These machines are used to create lightweight structural components that improve fuel efficiency without compromising safety. The automotive industry relies on aluminum extrusions for various applications, including chassis components and engine parts.

- Construction Sector: Aluminum profiles are commonly used in window frames, doors, and structural elements in buildings. Milling machines enable manufacturers to create custom shapes and sizes that meet specific architectural requirements.

- Electronics Production: Manufacturers utilize these machines to create housings and components that require precise dimensions for proper fit and function. The electronics industry often demands high-quality finishes and tight tolerances due to the compact nature of modern devices.

Maintenance Tips for Aluminum Extrusion Milling Machines

To ensure longevity and optimal performance of aluminum extrusion milling machines, regular maintenance is essential:

- Routine Cleaning: Regularly clean the machine's components to prevent buildup of aluminum shavings and coolant residues that can affect performance.

- Lubrication: Ensure all moving parts are adequately lubricated according to the manufacturer's specifications to reduce friction and wear.

- Calibration Checks: Periodically check the calibration of CNC systems to maintain precision in machining operations.

- Tool Inspection: Regularly inspect cutting tools for wear or damage; replace them as necessary to maintain machining quality.

- Software Updates: Keep software updated to benefit from new features or improvements that enhance functionality or efficiency.

Future Trends in Aluminum Extrusion Milling Technology

As technology continues to evolve, several trends are shaping the future of aluminum extrusion milling:

- Sustainability Practices: With increasing focus on sustainability, manufacturers are looking for ways to minimize waste during machining processes. Technologies that optimize material usage will become more prevalent.

- Smart Manufacturing: The integration of IoT (Internet of Things) technologies will enable smarter manufacturing processes where machines communicate with each other for optimized workflows.

- Advanced Materials Processing: Research into new alloys and materials will drive demand for milling machines capable of processing these advanced materials effectively.

Conclusion

High-quality aluminum extrusion milling machines are vital for achieving precision machining in various industries. With features such as robust construction, high spindle speeds, effective cooling systems, and advanced technological integration, these machines enhance productivity while ensuring superior quality outputs. As manufacturing continues to evolve with technological advancements, the capabilities of aluminum extrusion milling machines will undoubtedly expand further.

FAQ

1. What is an aluminum extrusion milling machine?

An aluminum extrusion milling machine is a specialized tool designed for cutting and shaping aluminum profiles through precise material removal processes.

2. How does a CNC system improve milling accuracy?

CNC systems allow for intricate programming that ensures consistent repeatability in machining operations, leading to higher accuracy in finished products.

3. Why is cooling important during the milling process?

Cooling is crucial because it prevents overheating of both the tool and the workpiece, reducing wear on tools and improving surface finishes on machined parts.

4. What types of industries use aluminum extrusion milling machines?

Industries such as aerospace, automotive manufacturing, construction, and electronics heavily rely on these machines for producing precision components.

5. How does automation benefit aluminum extrusion milling?

Automation increases production efficiency by reducing manual handling of parts and allowing for quicker tool changes and setup times.

Citations:

[1] https://www.speedtigertools.com/solution/ins.php?index_id=101

[2] https://www.cgmachina.com/aluminium-extrusion-cutting-machine/

[3] https://www.cgmachina.com/single-axis-copying-milling-machine-for-aluminum-profile-product/

[4] https://www.cgmachina.com/5-axis-end-milling-machine-for-aluminum-profile-product/

[5] https://www.youtube.com/watch?v=fb3f1etxO7Q

[6] https://www.youtube.com/watch?v=xRhuidnejfA

[7] https://demacmachine.com/aluminum-extrusion-machining-center/

[8] https://www.raptor-cnc.com/en/aluminum-milling.html

[9] https://www.decalumamachine.com/cnc-milling-machine/aluminum-profile-cnc-milling-machine-with-3.html

[10] https://www.istockphoto.com/photos/aluminum-cutting-machine

[11] https://www.youtube.com/watch?v=iiGlq7408ME