Content Menu

● Understanding Aluminum Extrusions

● Key Features of 10mm Aluminum Extrusions

>> Versatile Design Options

>> Lightweight Yet Strong

>> Corrosion Resistance

>> Ease of Fabrication

>> Aesthetic Appeal

● Applications of 10mm Aluminum Extrusions

>> Construction

>> Automotive

>> Aerospace

>> Furniture

>> Electronics

● Benefits of Using 10mm Aluminum Extrusions

>> Cost-Effectiveness

>> Sustainability

>> Thermal Conductivity

>> Customization

>> Safety

● Conclusion

● Frequently Asked Questions

>> 1. What is the maximum length for 10mm aluminum extrusions?

>> 2. Can 10mm aluminum extrusions be painted?

>> 3. What tools are needed to work with 10mm aluminum extrusions?

>> 4. Are 10mm aluminum extrusions suitable for outdoor use?

>> 5. How do I determine the right profile for my project?

Aluminum extrusions are a vital component in various industries, providing structural integrity and versatility in design. Among the different sizes available, 10mm aluminum extrusions stand out due to their unique features and applications. This article will explore the key characteristics of 10mm aluminum extrusions, their benefits, applications, and why they are a preferred choice for many projects.

Understanding Aluminum Extrusions

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy by forcing it through a die. This process allows for the creation of complex shapes and profiles that can be used in a wide range of applications. The resulting extrusions are lightweight, durable, and resistant to corrosion, making them ideal for both indoor and outdoor use.

Key Features of 10mm Aluminum Extrusions

Versatile Design Options

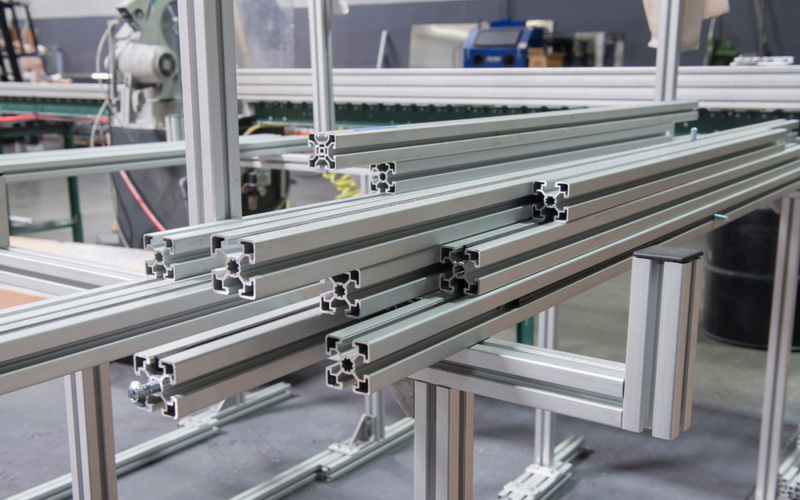

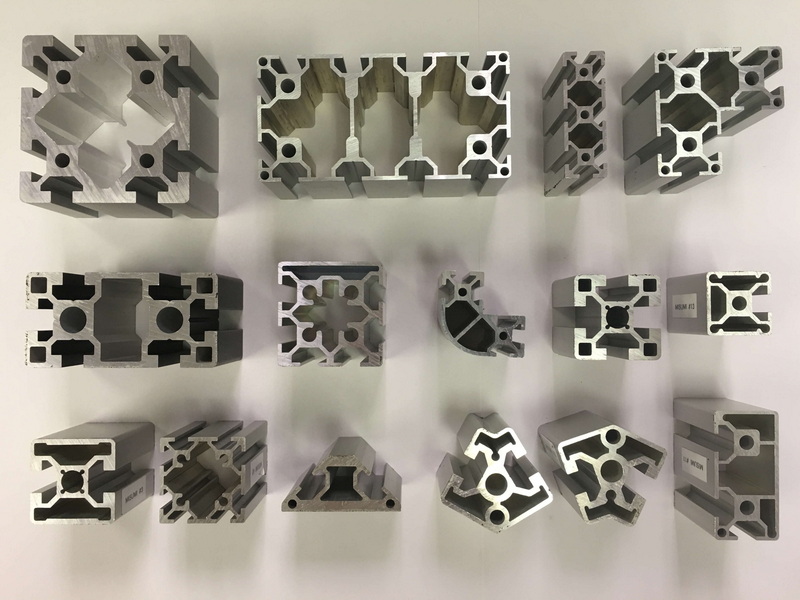

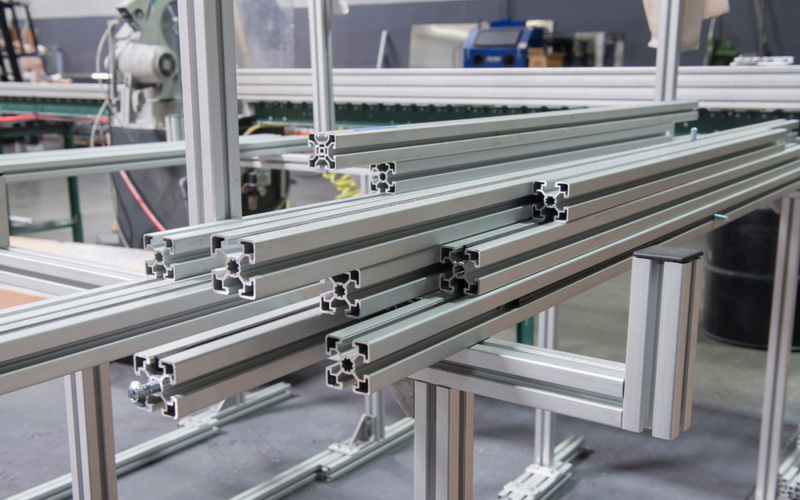

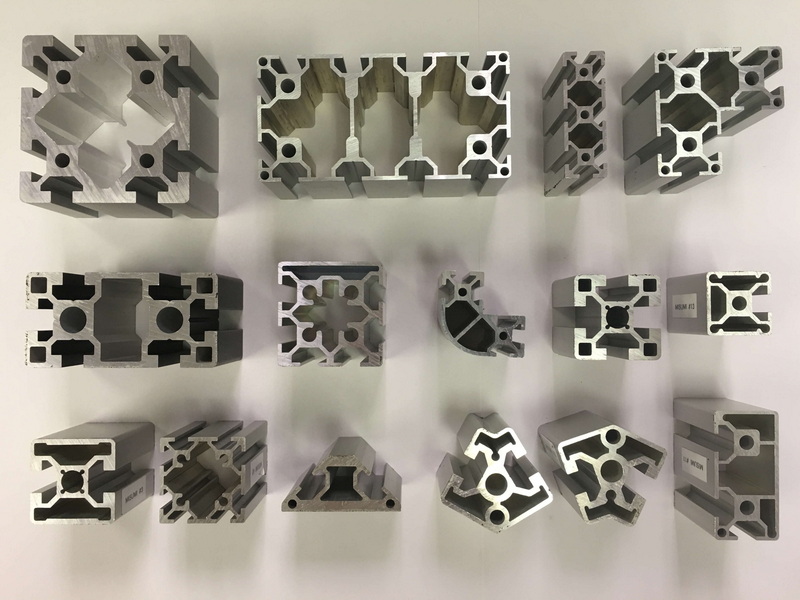

One of the most significant advantages of 10mm aluminum extrusions is their versatility in design. They can be manufactured in various shapes, including square, rectangular, and custom profiles. This flexibility allows engineers and designers to create components that meet specific project requirements. The ability to customize the design means that 10mm aluminum extrusions can be tailored to fit unique applications, whether for structural support or aesthetic purposes.

Lightweight Yet Strong

Aluminum is known for its lightweight properties, and 10mm extrusions are no exception. Despite their light weight, they offer excellent strength-to-weight ratios, making them suitable for applications where weight is a critical factor, such as in aerospace and automotive industries. This characteristic is particularly beneficial in reducing overall project weight without compromising structural integrity.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, which helps prevent corrosion. This property makes 10mm aluminum extrusions ideal for outdoor applications, such as in construction and landscaping, where exposure to the elements is a concern. The corrosion resistance of aluminum ensures that structures remain safe and visually appealing over time, reducing the need for frequent maintenance.

Ease of Fabrication

10mm aluminum extrusions can be easily cut, drilled, and machined to fit specific project needs. This ease of fabrication reduces labor costs and time, allowing for quicker project completion. Additionally, they can be welded or joined using various methods, including screws and brackets. The ability to work with these extrusions using standard tools makes them accessible for both professional fabricators and DIY enthusiasts.

Aesthetic Appeal

The sleek and modern appearance of aluminum extrusions makes them a popular choice for architectural applications. They can be anodized or painted to achieve different finishes, enhancing their aesthetic appeal while maintaining durability. This versatility in appearance allows designers to create visually striking structures that can blend seamlessly with various architectural styles.

Applications of 10mm Aluminum Extrusions

The versatility of 10mm aluminum extrusions allows them to be used in various applications across multiple industries:

Construction

In the construction industry, 10mm aluminum extrusions are used in framing, window and door systems, and structural supports. Their lightweight nature and strength make them ideal for creating durable and efficient building components. Additionally, their corrosion resistance ensures that they can withstand harsh environmental conditions.

Automotive

In the automotive sector, 10mm aluminum extrusions are employed in vehicle frames, body panels, and interior components due to their lightweight and strength. The use of aluminum in vehicles contributes to improved fuel efficiency and performance, making it a preferred material for modern automotive design.

Aerospace

The aerospace industry relies heavily on 10mm aluminum extrusions for aircraft structures and components where weight reduction is crucial. The lightweight nature of aluminum helps improve fuel efficiency and overall performance in aviation applications. Additionally, the corrosion resistance of aluminum is essential for ensuring the longevity and safety of aircraft.

Furniture

10mm aluminum extrusions are commonly found in modern furniture designs, providing a sleek and contemporary look. They are used in the construction of tables, chairs, and shelving units, offering both aesthetic appeal and structural support. The ability to customize the design of aluminum extrusions allows furniture designers to create unique pieces that stand out in any setting.

Electronics

In the electronics industry, 10mm aluminum extrusions are used in the manufacturing of enclosures and heat sinks for electronic devices. The excellent thermal conductivity of aluminum helps dissipate heat, ensuring that electronic components operate efficiently and safely. This application is particularly important in high-performance computing and consumer electronics.

Benefits of Using 10mm Aluminum Extrusions

Cost-Effectiveness

While the initial cost of aluminum may be higher than some materials, the long-term benefits, such as durability and low maintenance, make 10mm aluminum extrusions a cost-effective choice. Their longevity reduces the need for replacements and repairs, ultimately saving money over time.

Sustainability

Aluminum is a recyclable material, and using 10mm aluminum extrusions contributes to sustainable building practices. The recycling process requires only a fraction of the energy needed to produce new aluminum, making it an environmentally friendly option. This sustainability aspect is increasingly important as industries strive to reduce their carbon footprint.

Thermal Conductivity

Aluminum has excellent thermal conductivity, making 10mm extrusions suitable for applications requiring heat dissipation, such as in electronic devices and heat sinks. This property ensures that components remain cool during operation, enhancing performance and reliability.

Customization

Manufacturers can produce 10mm aluminum extrusions in various lengths and finishes, allowing for customization to meet specific project needs. This adaptability is crucial in industries where precision and design are paramount. Custom profiles can be created to fit unique applications, ensuring that the final product meets all requirements.

Safety

Aluminum is a non-combustible material, making 10mm aluminum extrusions a safe choice for construction and manufacturing applications. They do not emit toxic fumes when exposed to fire, enhancing safety in buildings and vehicles. This safety feature is particularly important in environments where fire hazards are a concern.

Conclusion

In summary, 10mm aluminum extrusions offer a unique combination of strength, versatility, and aesthetic appeal, making them a preferred choice in various industries. Their lightweight nature, corrosion resistance, and ease of fabrication further enhance their desirability for both structural and decorative applications. As industries continue to seek sustainable and efficient materials, 10mm aluminum extrusions will undoubtedly play a significant role in future innovations.

Frequently Asked Questions

1. What is the maximum length for 10mm aluminum extrusions?

The maximum length for 10mm aluminum extrusions can vary by manufacturer, but they are typically available in lengths up to 6 meters or more.

2. Can 10mm aluminum extrusions be painted?

Yes, 10mm aluminum extrusions can be painted or anodized to achieve different finishes and colors, enhancing their aesthetic appeal.

3. What tools are needed to work with 10mm aluminum extrusions?

Common tools include saws for cutting, drills for making holes, and various fastening tools for assembly.

4. Are 10mm aluminum extrusions suitable for outdoor use?

Yes, due to their corrosion resistance, 10mm aluminum extrusions are ideal for outdoor applications.

5. How do I determine the right profile for my project?

The right profile depends on the specific requirements of your project, including load-bearing needs, design preferences, and environmental factors.