Content Menu

● Understanding Aluminum Extrusions

● Key Dimensions of 15 Series Aluminum Extrusions

● Applications of 15 Series Aluminum Extrusions

● Benefits of Using 15 Series Aluminum Extrusions

● Conclusion

● Related Questions

>> 1. What are the typical applications of 15 series aluminum extrusions in construction?

>> 2. How do the mechanical properties of 15 series aluminum compare to other extrusion series?

>> 3. What are the environmental impacts of producing and using 15 series aluminum extrusions?

>> 4. Can 15 series aluminum extrusions be used in outdoor applications?

>> 5. How can I customize 15 series aluminum extrusions for my project?

Aluminum extrusions are widely used in various industries due to their lightweight, strength, and versatility. Among the different series of aluminum extrusions, the 15 series is particularly popular for its unique dimensions and applications. This article will explore the key dimensions of 15 series aluminum extrusions, their applications, and the benefits they offer.

Understanding Aluminum Extrusions

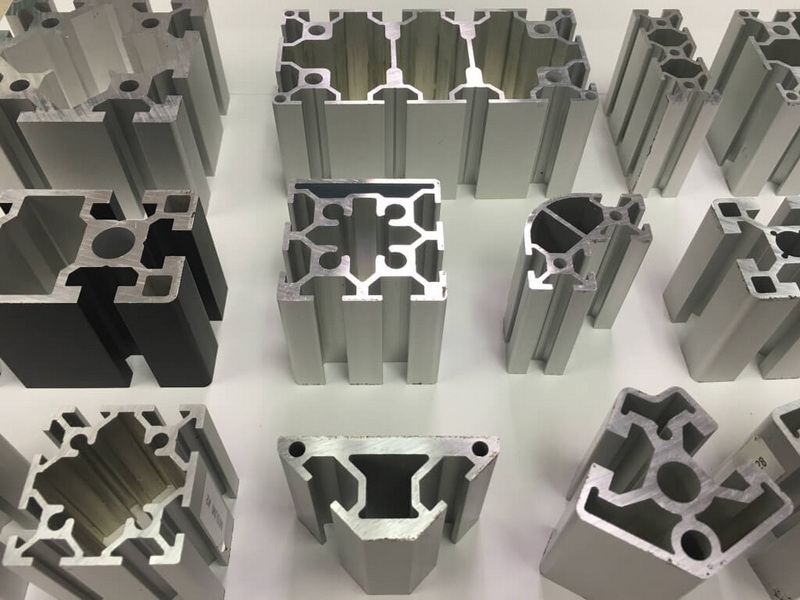

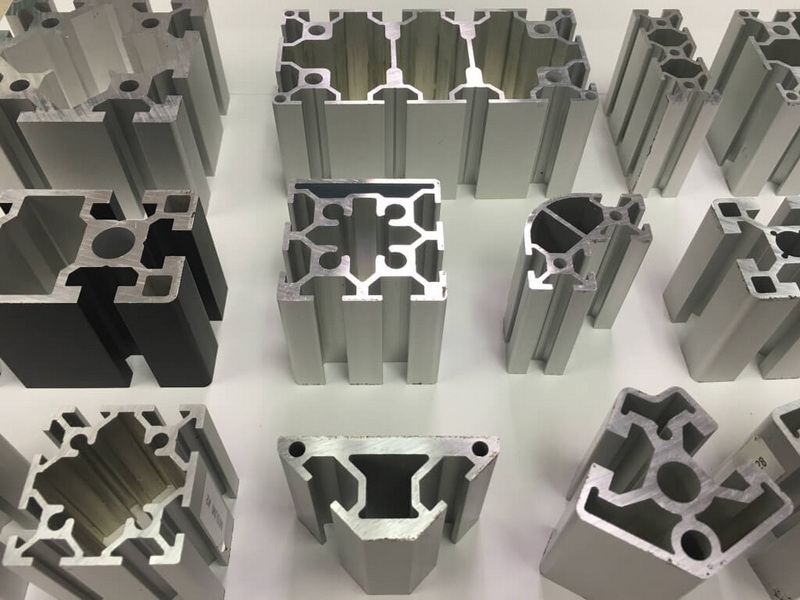

Aluminum extrusion is a process that involves forcing aluminum alloy through a die to create a specific cross-sectional shape. This process allows for the production of complex shapes that can be used in a variety of applications. The 15 series aluminum extrusions are characterized by their specific dimensions, which make them suitable for various structural and architectural applications.

Key Dimensions of 15 Series Aluminum Extrusions

The 15 series aluminum extrusions are defined by their nominal dimensions, which typically include a width of 15 mm and a height that can vary depending on the specific profile. The most common profiles in the 15 series include:

- 15x15 mm: A square profile that is often used in framing applications.

- 15x30 mm: A rectangular profile that provides greater strength and is commonly used in structural applications.

- 15x45 mm: This profile is used for applications requiring additional strength and rigidity.

These dimensions are crucial as they determine the load-bearing capacity and the overall strength of the extrusion. The wall thickness of the profiles also plays a significant role in their performance, with thicker walls providing greater strength and durability.

Applications of 15 Series Aluminum Extrusions

The versatility of 15 series aluminum extrusions makes them suitable for a wide range of applications, including:

- Framing Systems: The 15 series is commonly used in the construction of frames for machinery, equipment, and enclosures. The lightweight nature of aluminum allows for easy handling and assembly.

- Automotive Industry: In the automotive sector, 15 series extrusions are used for structural components, providing strength without adding excessive weight to vehicles.

- Furniture Manufacturing: The aesthetic appeal and strength of 15 series extrusions make them ideal for modern furniture designs, including tables, chairs, and shelving units.

- Display Systems: Retail displays and exhibition stands often utilize 15 series extrusions due to their ability to create customizable and modular designs.

Benefits of Using 15 Series Aluminum Extrusions

There are several advantages to using 15 series aluminum extrusions in various applications:

- Lightweight: Aluminum is significantly lighter than steel, making it easier to transport and handle during installation.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion and suitable for outdoor applications.

- Customizability: The extrusion process allows for a wide range of shapes and sizes, enabling manufacturers to create custom solutions for specific needs.

- Recyclability: Aluminum is 100% recyclable, making it an environmentally friendly choice for construction and manufacturing.

Conclusion

The 15 series aluminum extrusions offer a unique combination of dimensions, strength, and versatility, making them a popular choice in various industries. Their lightweight nature, corrosion resistance, and customizability further enhance their appeal, allowing for innovative designs and applications.

Related Questions

1. What are the typical applications of 15 series aluminum extrusions in construction?

15 series aluminum extrusions are commonly used in framing systems, structural components, and architectural applications due to their lightweight and strong properties.

2. How do the mechanical properties of 15 series aluminum compare to other extrusion series?

The 15 series aluminum extrusions typically offer a good balance of strength and weight, making them suitable for applications where both properties are essential. Compared to other series, they may have lower load-bearing capacities but are easier to handle and assemble.

3. What are the environmental impacts of producing and using 15 series aluminum extrusions?

The production of aluminum extrusions has a lower environmental impact compared to other materials, especially when considering the recyclability of aluminum. Using recycled aluminum can significantly reduce energy consumption and greenhouse gas emissions.

4. Can 15 series aluminum extrusions be used in outdoor applications?

Yes, 15 series aluminum extrusions are suitable for outdoor applications due to their corrosion resistance, making them ideal for use in environments exposed to moisture and other elements.

5. How can I customize 15 series aluminum extrusions for my project?

Customization can be achieved through the extrusion process, where specific shapes and sizes can be designed to meet project requirements. Additionally, surface treatments and finishes can enhance the aesthetic appeal and performance of the extrusions.