Content Menu

● Introduction

● Understanding T-Slot Aluminum Extrusions

● Key Benefits of T-Slot Aluminum Extrusions

>> Versatility

>> Strength and Durability

>> Ease of Assembly

>> Cost-Effectiveness

● Common Applications of T-Slot Aluminum Extrusions

>> Industrial Machinery

>> Workstations and Automation

>> Custom Projects

● Conclusion

● Related Questions

>> 1. What materials are T-slot aluminum extrusions made from?

>> 2. Can T-slot aluminum extrusions be used outdoors?

>> 3. How do I cut T-slot aluminum extrusions?

>> 4. Are T-slot aluminum extrusions customizable?

>> 5. What are the weight limits for T-slot aluminum extrusions?

Introduction

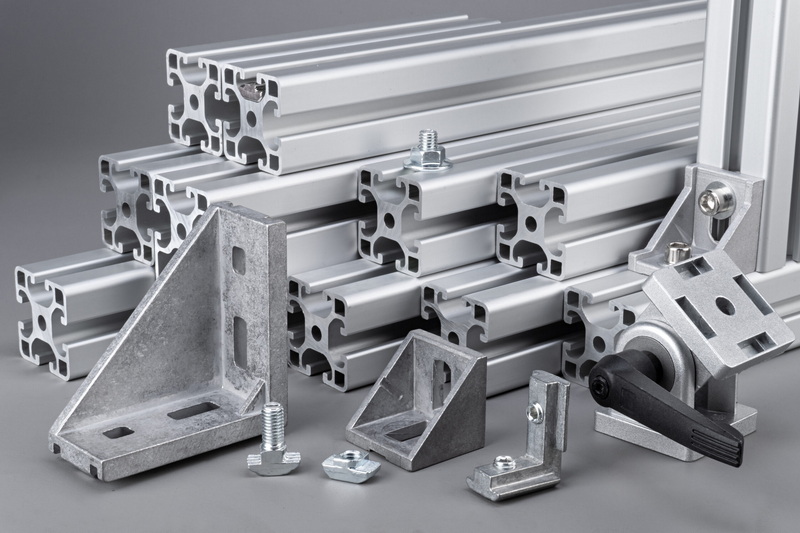

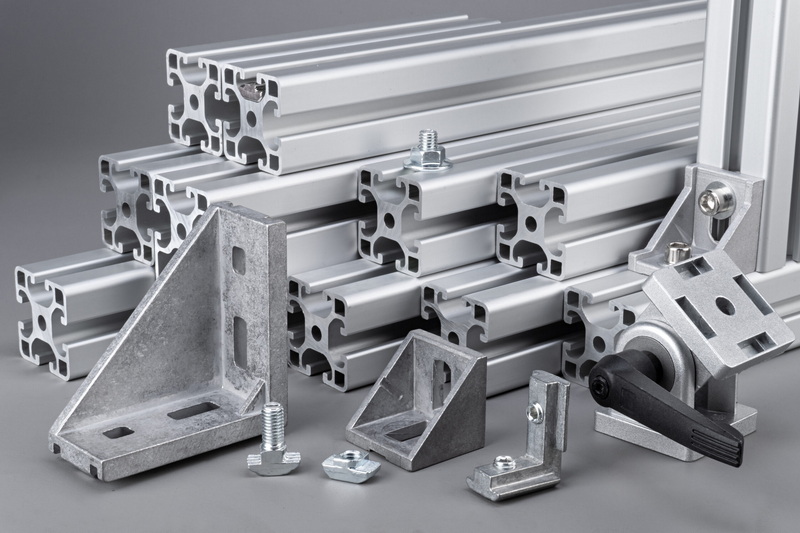

Aluminum extrusion has become a cornerstone in modern engineering and manufacturing, providing versatile solutions for a wide range of applications. Among the various types of aluminum extrusions, T-slot aluminum extrusions stand out due to their unique design and functionality. These extrusions feature a T-shaped groove that allows for easy assembly and customization, making them ideal for building frames, workstations, and other structures. In this article, we will explore the key benefits of using T-slot aluminum extrusions in your projects, highlighting their versatility, strength, ease of assembly, and cost-effectiveness.

Understanding T-Slot Aluminum Extrusions

T-slot aluminum extrusions are profiles made from aluminum that have a T-shaped groove running along their length. This design allows for the easy attachment of various components, such as brackets, connectors, and panels, without the need for complex tools or specialized skills. The T-slot design is not only functional but also aesthetically pleasing, making it a popular choice for both industrial and commercial applications.

One of the primary advantages of T-slot aluminum extrusions is their modularity. This means that they can be easily reconfigured or expanded as project requirements change. Unlike traditional construction methods, which often require significant time and resources to modify, T-slot systems can be adjusted quickly and efficiently, saving both time and money.

Key Benefits of T-Slot Aluminum Extrusions

Versatility

T-slot aluminum extrusions are incredibly versatile, making them suitable for a wide range of applications. Whether you are designing a custom workstation, building a machine frame, or creating a display stand, T-slot extrusions can be adapted to meet your specific needs. The modular nature of these extrusions allows for endless configurations, enabling designers and engineers to create unique solutions tailored to their projects.

For instance, in manufacturing environments, T-slot aluminum extrusions can be used to construct assembly lines, conveyor systems, and safety barriers. In office settings, they can be utilized to create ergonomic workstations, shelving units, and partition walls. The possibilities are virtually limitless, making T-slot aluminum extrusions a go-to choice for many industries.

Strength and Durability

Aluminum is known for its excellent strength-to-weight ratio, and T-slot aluminum extrusions are no exception. These extrusions are designed to withstand significant loads while remaining lightweight, making them ideal for applications where weight is a concern. The inherent properties of aluminum, such as resistance to corrosion and rust, further enhance the durability of T-slot systems, ensuring they can withstand harsh environments and prolonged use.

In addition to their strength, T-slot aluminum extrusions are also designed to be rigid and stable. This stability is crucial in applications where precision and accuracy are paramount, such as in machinery and automation systems. The ability to maintain structural integrity under load makes T-slot aluminum extrusions a reliable choice for engineers and designers.

Ease of Assembly

One of the standout features of T-slot aluminum extrusions is their ease of assembly. The T-shaped grooves allow for quick and straightforward connections between different components, eliminating the need for complex tools or extensive training. This user-friendly design means that even those with minimal experience can assemble structures efficiently.

The assembly process typically involves sliding connectors or brackets into the T-slots and securing them with fasteners. This simplicity not only speeds up the construction process but also allows for easy disassembly and reconfiguration. If project requirements change, components can be removed and repositioned without damaging the existing structure.

Cost-Effectiveness

When considering the overall cost of a project, T-slot aluminum extrusions offer significant savings in both time and materials. The modular design reduces the need for custom fabrication, which can be time-consuming and expensive. Instead, standard T-slot profiles can be cut to length and assembled on-site, minimizing labor costs and material waste.

Furthermore, the durability of aluminum means that structures built with T-slot extrusions require less maintenance and have a longer lifespan compared to traditional materials. This longevity translates to lower replacement costs and reduced downtime, making T-slot aluminum extrusions a cost-effective solution for businesses.

Common Applications of T-Slot Aluminum Extrusions

Industrial Machinery

T-slot aluminum extrusions are widely used in the construction of industrial machinery. Their strength and stability make them ideal for building frames that support heavy equipment and components. For example, manufacturers often use T-slot systems to create custom machine bases, enclosures, and safety guards. The ability to easily modify these structures allows manufacturers to adapt to changing production needs without significant downtime.

Workstations and Automation

In modern manufacturing environments, efficient workstations are essential for productivity. T-slot aluminum extrusions provide the flexibility needed to design ergonomic workstations that can be tailored to individual tasks. Adjustable height desks, tool storage solutions, and integrated lighting can all be achieved using T-slot systems.

Additionally, T-slot aluminum extrusions play a crucial role in automation. They are commonly used to build conveyor systems, robotic arms, and assembly lines. The modular nature of T-slot designs allows for quick adjustments and expansions, ensuring that automation systems can evolve alongside production demands.

Custom Projects

The versatility of T-slot aluminum extrusions makes them an excellent choice for custom projects across various industries. From creating unique display stands for trade shows to building specialized equipment for research and development, T-slot systems can be tailored to meet specific requirements. The ability to easily modify and reconfigure these structures means that businesses can innovate and adapt without the constraints of traditional construction methods.

Conclusion

T-slot aluminum extrusions offer a multitude of benefits that make them an ideal choice for a wide range of projects. Their versatility, strength, ease of assembly, and cost-effectiveness set them apart from traditional construction materials. As industries continue to evolve and demand more efficient solutions, T-slot aluminum extrusions will undoubtedly play a significant role in shaping the future of engineering and manufacturing.

By leveraging the advantages of T-slot systems, businesses can enhance their productivity, reduce costs, and create innovative solutions that meet the demands of modern projects. Whether you are an engineer, designer, or manufacturer, considering T-slot aluminum extrusions for your next project could lead to significant improvements in efficiency and effectiveness.

Related Questions

1. What materials are T-slot aluminum extrusions made from?

T-slot aluminum extrusions are primarily made from aluminum, which is known for its lightweight and durable properties. Some extrusions may also include additional materials for specific applications, but aluminum remains the primary component.

2. Can T-slot aluminum extrusions be used outdoors?

Yes, T-slot aluminum extrusions are suitable for outdoor use due to their resistance to corrosion and rust. However, it is essential to consider environmental factors and choose appropriate finishes for prolonged exposure to the elements.

3. How do I cut T-slot aluminum extrusions?

T-slot aluminum extrusions can be cut using standard cutting tools such as miter saws or band saws. It is recommended to use a blade designed for cutting aluminum to ensure clean cuts and prevent damage to the material.

4. Are T-slot aluminum extrusions customizable?

Yes, T-slot aluminum extrusions are highly customizable. They can be cut to specific lengths, and various connectors and accessories can be added to create unique configurations tailored to individual project needs.

5. What are the weight limits for T-slot aluminum extrusions?

The weight limits for T-slot aluminum extrusions depend on the specific profile and design used. Generally, T-slot systems are engineered to support significant loads, but it is essential to consult manufacturer specifications for precise weight limits based on the application.