Content Menu

● Introduction

● The Aluminum Extrusion Process

● Benefits of Square Aluminum Profiles

>> Strength and Durability

>> Lightweight Nature and Corrosion Resistance

>> Versatility in Design and Application

● Common Applications of Square Aluminum Extrusions

● Choosing Custom Aluminum Extrusions

● Latest Techniques in Aluminum Extrusion Manufacturing

● Conclusion

● Related Questions

>> 1. What are the advantages of using aluminum over steel in construction?

>> 2. How can square aluminum profiles be customized for specific projects?

>> 3. What are the common alloys used for square aluminum profiles?

>> 4. How does the anodizing process enhance aluminum profiles?

>> 5. What are the environmental benefits of using aluminum in construction?

Introduction

In the realm of construction, materials play a pivotal role in determining the strength, durability, and aesthetic appeal of structures. Among the various materials available, aluminum has emerged as a popular choice due to its unique properties. Square aluminum profiles, in particular, have gained traction for their versatility and functionality. This article delves into the key benefits of using square aluminum profiles in construction, exploring their applications, advantages, and the processes involved in their production.

The Aluminum Extrusion Process

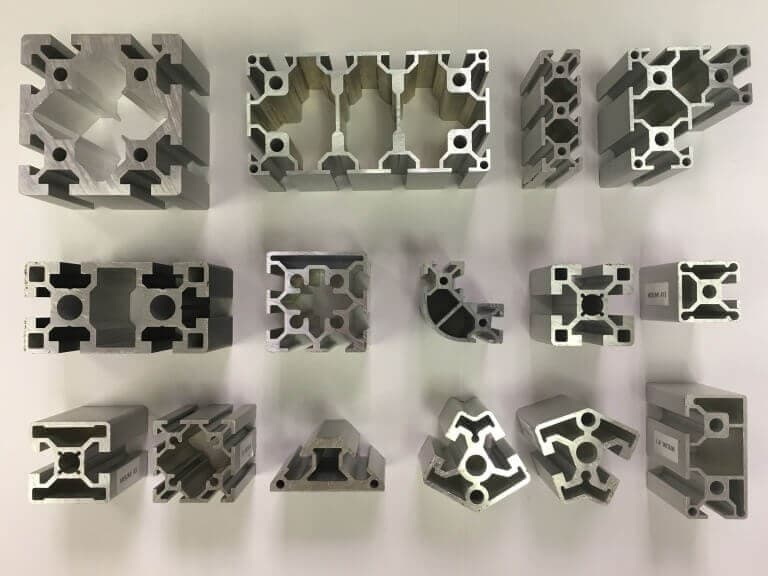

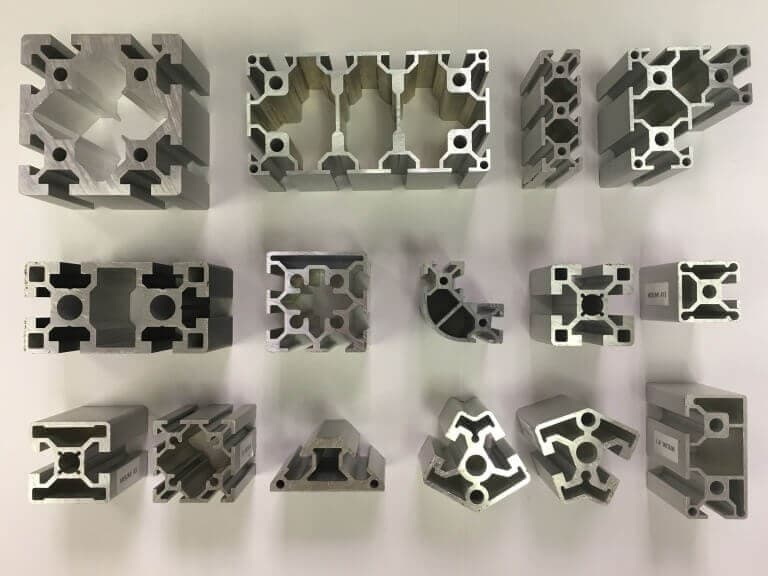

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy by forcing it through a die. This process allows for the creation of complex shapes and profiles, including square aluminum profiles. The extrusion process begins with heating aluminum billets to a specific temperature, making them malleable. Once heated, the aluminum is pushed through a die, which shapes it into the desired profile.

The choice of aluminum alloy is crucial in this process. Different alloys offer varying levels of strength, corrosion resistance, and workability. Common alloys used for square aluminum profiles include 6061 and 6063, known for their excellent mechanical properties and surface finish. The design of the die is also essential, as it determines the final shape and dimensions of the extruded product.

Benefits of Square Aluminum Profiles

Strength and Durability

One of the primary benefits of square aluminum profiles is their strength. Aluminum is known for its high strength-to-weight ratio, making it an ideal material for construction. Square profiles provide structural integrity, allowing them to support significant loads while remaining lightweight. This characteristic is particularly advantageous in applications where weight reduction is critical, such as in high-rise buildings and bridges.

Moreover, aluminum is inherently resistant to corrosion, which enhances the longevity of structures. Unlike steel, which can rust over time, aluminum forms a protective oxide layer that prevents further oxidation. This property makes square aluminum profiles suitable for both indoor and outdoor applications, ensuring that they maintain their structural integrity over time.

Lightweight Nature and Corrosion Resistance

The lightweight nature of square aluminum profiles is another significant advantage. This feature simplifies transportation and installation, reducing labor costs and time on construction sites. Builders can easily handle and maneuver aluminum profiles, making them a preferred choice for various construction projects.

In addition to being lightweight, aluminum's corrosion resistance is a critical factor in its selection for construction. Square aluminum profiles can withstand harsh environmental conditions, including exposure to moisture, chemicals, and UV radiation. This resistance minimizes maintenance requirements and extends the lifespan of structures, ultimately leading to cost savings for builders and property owners.

Versatility in Design and Application

Square aluminum profiles offer remarkable versatility in design. They can be easily cut, welded, and joined to create custom structures tailored to specific project requirements. This adaptability allows architects and engineers to explore innovative designs without compromising on structural integrity.

The applications of square aluminum profiles in construction are vast. They are commonly used in window frames, door frames, curtain walls, and structural supports. Additionally, their aesthetic appeal makes them suitable for architectural features, such as facades and decorative elements. The ability to anodize or powder-coat aluminum profiles further enhances their visual appeal, allowing for a wide range of colors and finishes.

Common Applications of Square Aluminum Extrusions

Square aluminum profiles find extensive use in various construction applications. Some of the most common applications include:

- Window and Door Frames: Square aluminum profiles provide a sturdy framework for windows and doors, ensuring durability and energy efficiency. Their lightweight nature allows for larger openings without compromising structural integrity.

- Curtain Walls: In modern architecture, curtain walls are often constructed using square aluminum profiles. These walls provide a sleek, contemporary look while allowing for large glass panels that enhance natural light.

- Structural Supports: Square aluminum profiles are frequently used as structural supports in buildings and bridges. Their strength and lightweight properties make them ideal for load-bearing applications.

- Railings and Fencing: Aluminum profiles are also used in railings and fencing, providing safety and security while maintaining an attractive appearance.

- Architectural Features: Square aluminum profiles can be utilized in various architectural features, such as canopies, awnings, and decorative elements, adding visual interest to buildings.

Choosing Custom Aluminum Extrusions

When selecting square aluminum profiles for construction projects, several factors must be considered. These include:

- Alloy Type: Different aluminum alloys offer varying properties. It is essential to choose an alloy that meets the specific requirements of the project, such as strength, corrosion resistance, and workability.

- Dimensions: The dimensions of the square profiles should align with the design specifications. Custom extrusions can be produced to meet unique size requirements.

- Surface Finish: The surface finish of aluminum profiles can significantly impact their appearance and performance. Options such as anodizing and powder coating can enhance corrosion resistance and aesthetic appeal.

- Supplier Reputation: Working with reputable suppliers is crucial to ensure the quality of aluminum profiles. A reliable supplier will provide high-quality products and support throughout the project.

Latest Techniques in Aluminum Extrusion Manufacturing

The aluminum extrusion industry is continually evolving, with new techniques and technologies emerging to improve efficiency and sustainability. Some of the latest advancements include:

- 3D Printing and Additive Manufacturing: The integration of 3D printing technology in aluminum extrusion allows for the rapid prototyping of complex shapes and designs. This innovation streamlines the design process and reduces material waste.

- Sustainable Practices: Many manufacturers are adopting sustainable practices in aluminum production, such as recycling scrap aluminum and using energy-efficient processes. This shift not only reduces environmental impact but also lowers production costs.

- Advanced Automation: Automation in the extrusion process enhances precision and efficiency. Automated systems can monitor and control various parameters, ensuring consistent quality in the final product.

Conclusion

Square aluminum profiles offer numerous benefits that make them an excellent choice for construction projects. Their strength, lightweight nature, corrosion resistance, and versatility in design contribute to their growing popularity in the industry. As construction continues to evolve, the demand for innovative materials like square aluminum profiles will only increase, paving the way for more sustainable and efficient building practices.

Related Questions

1. What are the advantages of using aluminum over steel in construction?

Aluminum is lighter than steel, making it easier to handle and transport. It also has superior corrosion resistance, which reduces maintenance costs and extends the lifespan of structures.

2. How can square aluminum profiles be customized for specific projects?

Square aluminum profiles can be customized in terms of size, alloy type, and surface finish. Manufacturers can produce profiles to meet unique design specifications.

3. What are the common alloys used for square aluminum profiles?

Common alloys for square aluminum profiles include 6061 and 6063, known for their excellent mechanical properties and corrosion resistance.

4. How does the anodizing process enhance aluminum profiles?

Anodizing creates a protective oxide layer on the surface of aluminum, enhancing its corrosion resistance and allowing for a variety of colors and finishes.

5. What are the environmental benefits of using aluminum in construction?

Aluminum is highly recyclable, and using recycled aluminum reduces energy consumption and greenhouse gas emissions. Sustainable practices in aluminum production further minimize environmental impact.