Content Menu

● Introduction

● The Aluminum Extrusion Process

● Benefits of Round Aluminum Profiles

>> Lightweight Yet Strong

>> Corrosion Resistance

>> Versatility in Design

>> Customization Options

>> Sustainability

● Applications of Round Aluminum Extrusions

● Anodized Aluminum Extrusions

● Design Considerations for Aluminum Extrusions

● Conclusion

● Related Questions

>> 1. What are the main advantages of using aluminum in construction?

>> 2. How does the anodization process enhance aluminum profiles?

>> 3. Can round aluminum profiles be customized for specific projects?

>> 4. What are some common applications of round aluminum profiles in construction?

>> 5. How does using aluminum contribute to sustainable construction practices?

Introduction

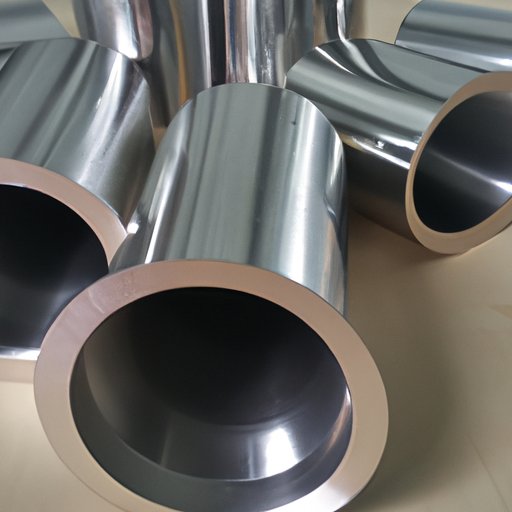

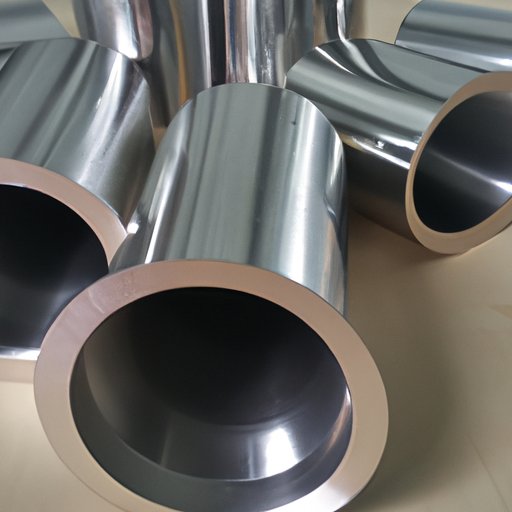

Aluminum has become a staple material in the construction industry due to its unique properties, including lightweight, strength, and resistance to corrosion. Among the various forms of aluminum, round aluminum profiles stand out for their versatility and functionality. These profiles are created through a process known as aluminum extrusion, where aluminum is forced through a die to create specific shapes. This article explores the key benefits of using round aluminum profiles in construction, highlighting their applications, advantages, and design considerations.

The Aluminum Extrusion Process

The aluminum extrusion process is a critical step in creating round aluminum profiles. It begins with heating aluminum billets to a malleable state, allowing them to be easily shaped. The heated aluminum is then pushed through a die, which determines the final shape of the profile. This process can produce a wide variety of shapes, including round profiles, which are particularly useful in construction applications.

The extrusion process offers several advantages, including the ability to create complex shapes with high precision. Additionally, it allows for the production of long lengths of aluminum profiles, which can be cut to size as needed. This efficiency makes aluminum extrusion a popular choice for manufacturers and builders alike.

Benefits of Round Aluminum Profiles

Lightweight Yet Strong

One of the most significant benefits of round aluminum profiles is their lightweight nature. Aluminum is much lighter than steel, making it easier to handle and transport. This characteristic is particularly advantageous in construction, where reducing the weight of materials can lead to lower transportation costs and easier installation.

Despite their lightweight nature, round aluminum profiles are incredibly strong. Aluminum has a high strength-to-weight ratio, meaning it can support substantial loads without adding excessive weight to a structure. This strength is crucial in construction applications, where safety and durability are paramount.

Corrosion Resistance

Round aluminum profiles are naturally resistant to corrosion, thanks to a protective oxide layer that forms on their surface when exposed to air. This corrosion resistance is particularly beneficial in construction, where materials are often exposed to harsh environmental conditions, including moisture, chemicals, and UV radiation.

The longevity of round aluminum profiles reduces the need for frequent maintenance and replacement, making them a cost-effective choice for builders. Structures that utilize aluminum profiles can maintain their aesthetic appeal and structural integrity over time, even in challenging environments.

Versatility in Design

Round aluminum profiles offer exceptional versatility in design. They can be used in a wide range of applications, from structural components to decorative elements. Their smooth, rounded edges provide a modern aesthetic that can enhance the overall appearance of a building.

Architects and designers appreciate the flexibility of round aluminum profiles, as they can be easily integrated into various architectural styles. Whether used in railings, columns, or window frames, these profiles can complement both contemporary and traditional designs.

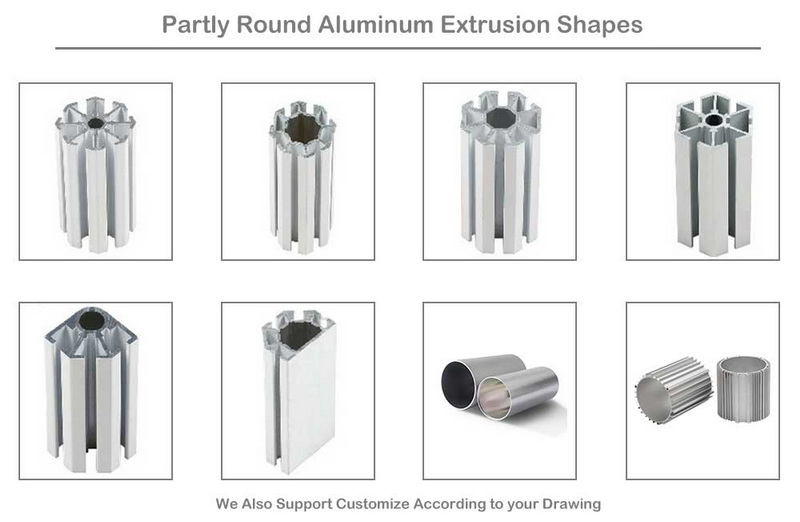

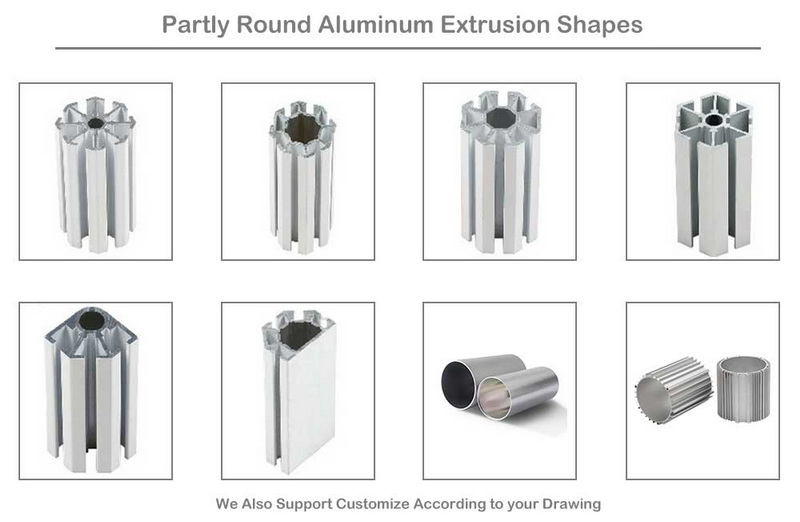

Customization Options

Another significant advantage of round aluminum profiles is the ability to customize them to meet specific project requirements. Manufacturers can create custom dies to produce profiles with unique dimensions, shapes, and finishes. This customization allows builders to tailor their materials to fit the specific needs of their projects.

Custom round aluminum profiles can be designed to accommodate various applications, including structural support, aesthetic features, and functional components. This level of customization ensures that builders can achieve their desired outcomes without compromising on quality or performance.

Sustainability

Sustainability is an increasingly important consideration in the construction industry. Round aluminum profiles are an environmentally friendly choice, as aluminum is highly recyclable. The recycling process requires only a fraction of the energy needed to produce new aluminum, making it a sustainable option for builders.

Using round aluminum profiles can contribute to green building certifications, such as LEED (Leadership in Energy and Environmental Design). By choosing sustainable materials, builders can reduce their environmental impact and promote eco-friendly practices in construction.

Applications of Round Aluminum Extrusions

Round aluminum profiles are used in various construction applications, showcasing their versatility and functionality. Some common applications include:

- Structural Support: Round aluminum profiles are often used as columns, beams, and trusses in building frameworks. Their strength and lightweight nature make them ideal for supporting heavy loads while minimizing overall weight.

- Railings and Fencing: The smooth, rounded edges of aluminum profiles make them an excellent choice for railings and fencing. They provide safety and security while enhancing the aesthetic appeal of outdoor spaces.

- Window and Door Frames: Round aluminum profiles are commonly used in window and door frames due to their durability and resistance to weathering. They can be designed to accommodate various glazing options, providing energy efficiency and aesthetic appeal.

- Decorative Elements: Architects often use round aluminum profiles for decorative features, such as canopies, awnings, and architectural accents. Their versatility allows for creative design solutions that enhance the overall appearance of a building.

Anodized Aluminum Extrusions

Anodization is a process that enhances the natural properties of aluminum, providing additional benefits for round aluminum profiles. During anodization, the aluminum surface is treated to create a thicker oxide layer, which improves corrosion resistance and durability.

Anodized round aluminum profiles are available in various colors and finishes, allowing for greater design flexibility. This process not only enhances the aesthetic appeal of the profiles but also increases their resistance to scratches and wear, making them suitable for high-traffic areas.

Design Considerations for Aluminum Extrusions

When designing with round aluminum profiles, several key factors should be considered to optimize performance and cost-effectiveness:

- Load-Bearing Capacity: Understanding the load requirements of a project is essential when selecting round aluminum profiles. Engineers should calculate the expected loads and choose profiles that can safely support them.

- Environmental Conditions: The environmental conditions in which the profiles will be used should also be considered. Factors such as exposure to moisture, chemicals, and UV radiation can impact the performance and longevity of aluminum profiles.

- Aesthetic Preferences: Designers should consider the overall aesthetic goals of the project when selecting round aluminum profiles. The smooth, rounded edges can complement various architectural styles, but the choice of finishes and colors can further enhance the design.

- Cost Considerations: While round aluminum profiles offer numerous benefits, it is essential to balance performance and cost. Builders should evaluate the total cost of materials, including any customization or finishing processes, to ensure the project remains within budget.

Conclusion

Round aluminum profiles offer a multitude of benefits for construction applications, including their lightweight nature, strength, corrosion resistance, and design versatility. The aluminum extrusion process allows for the creation of custom profiles that meet specific project requirements, making them an ideal choice for builders and architects alike. As sustainability becomes increasingly important in the construction industry, round aluminum profiles provide an eco-friendly option that contributes to green building practices.

By understanding the advantages and applications of round aluminum profiles, builders can make informed decisions that enhance the quality and durability of their projects. Whether used for structural support, decorative elements, or functional components, round aluminum profiles are a valuable addition to any construction endeavor.

Related Questions

1. What are the main advantages of using aluminum in construction?

Aluminum is lightweight, strong, corrosion-resistant, and highly versatile, making it an ideal material for various construction applications.

2. How does the anodization process enhance aluminum profiles?

Anodization creates a thicker oxide layer on aluminum, improving corrosion resistance, durability, and aesthetic appeal through various color options.

3. Can round aluminum profiles be customized for specific projects?

Yes, manufacturers can create custom round aluminum profiles to meet specific dimensions, shapes, and finishes required for various applications.

4. What are some common applications of round aluminum profiles in construction?

Round aluminum profiles are commonly used for structural support, railings, window and door frames, and decorative elements in buildings.

5. How does using aluminum contribute to sustainable construction practices?

Aluminum is highly recyclable, requiring less energy to recycle than to produce new aluminum, making it an environmentally friendly choice for builders.