Content Menu

● Understanding Aluminum Extrusion

● The Process of Aluminum Extrusion

● Key Benefits of Round Aluminum Extrusion Profiles

>> 1. Lightweight and Strong

>> 2. Corrosion Resistance

>> 3. Versatility in Design

>> 4. Cost-Effectiveness

>> 5. Excellent Thermal Conductivity

>> 6. Easy to Fabricate and Assemble

>> 7. Eco-Friendly Material

>> 8. Aesthetic Appeal

>> 9. High Strength and Durability

>> 10. Wide Range of Applications

● Conclusion

● Frequently Asked Questions

>> 1. What are the common applications of round aluminum extrusion profiles?

>> 2. How does the aluminum extrusion process work?

>> 3. What are the advantages of using aluminum over other materials?

>> 4. Can round aluminum extrusion profiles be customized?

>> 5. Is aluminum extrusion cost-effective?

Understanding Aluminum Extrusion

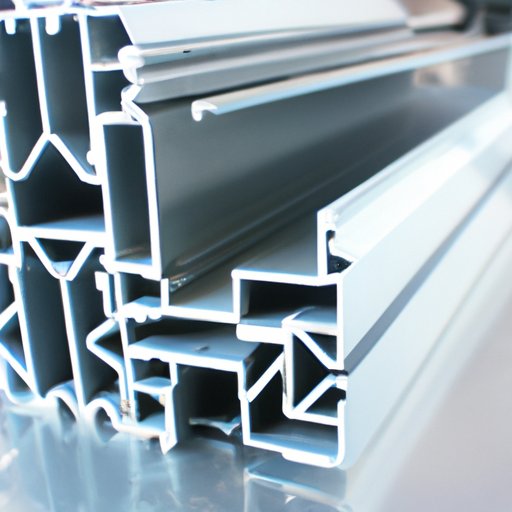

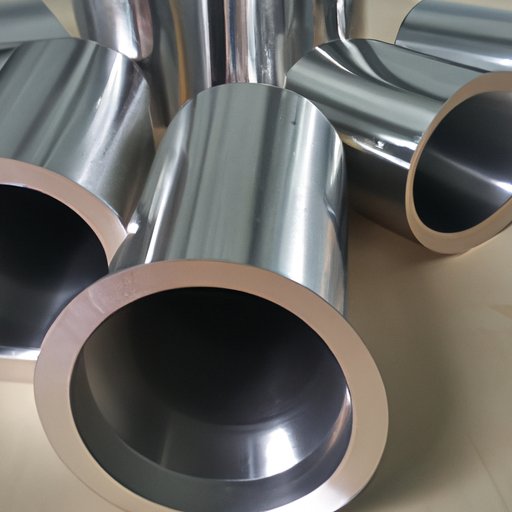

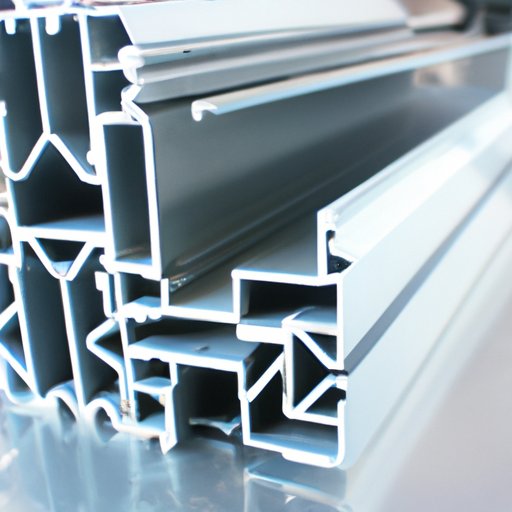

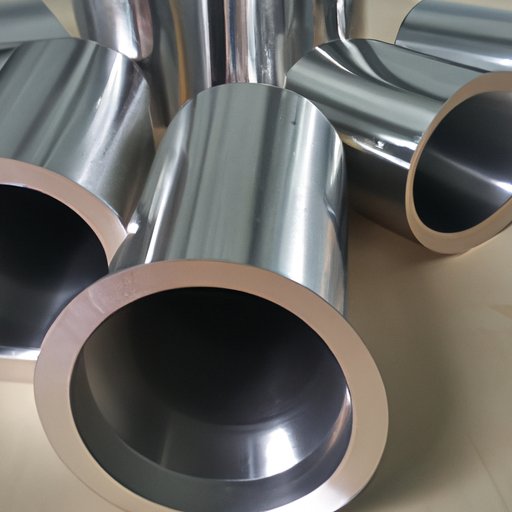

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This process is widely used in various industries due to its versatility, strength, and lightweight properties. Among the many shapes produced through aluminum extrusion, round profiles are particularly popular. This article explores the key benefits of using round aluminum extrusion profiles, highlighting their applications, advantages, and the reasons behind their growing popularity.

The Process of Aluminum Extrusion

The aluminum extrusion process involves several key steps that ensure the production of high-quality profiles.

1. Material Selection: The first step in the extrusion process is selecting the appropriate aluminum alloy. Different alloys offer varying properties, such as strength, corrosion resistance, and machinability. Common alloys used in extrusion include 6061 and 6063, which are known for their excellent mechanical properties and workability.

2. Heating: The selected aluminum alloy is heated to a specific temperature, typically between 350°C and 500°C, making it malleable and easier to shape. This heating process is crucial, as it allows the aluminum to flow smoothly through the die.

3. Extrusion: The heated aluminum is then forced through a die using a hydraulic press. The die determines the shape of the final product, which can be round, square, or any custom shape. The extrusion process can be done in two ways: direct extrusion, where the aluminum is pushed through the die, and indirect extrusion, where the die moves towards the aluminum.

4. Cooling: After extrusion, the profiles are cooled, typically using air or water, to solidify the shape. This cooling process is essential to ensure that the profiles maintain their dimensions and structural integrity.

5. Cutting and Finishing: Once cooled, the extruded profiles are cut to the desired length and may undergo additional finishing processes, such as anodizing or painting, to enhance their appearance and durability. Anodizing, in particular, provides a protective layer that increases corrosion resistance and allows for various color finishes.

Key Benefits of Round Aluminum Extrusion Profiles

1. Lightweight and Strong

One of the most significant advantages of round aluminum extrusion profiles is their lightweight nature. Aluminum is known for its high strength-to-weight ratio, making it an ideal material for applications where weight is a concern. This property is particularly beneficial in industries such as aerospace, automotive, and construction, where reducing weight can lead to improved fuel efficiency and easier handling. For example, in the aerospace industry, using lightweight materials can significantly reduce the overall weight of an aircraft, leading to lower fuel consumption and increased payload capacity.

2. Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, which helps prevent corrosion. This characteristic makes round aluminum extrusion profiles suitable for outdoor applications and environments where moisture and chemicals are present. Industries such as marine, automotive, and construction benefit from this property, as it ensures the longevity and durability of the products. For instance, aluminum boat frames and railings can withstand harsh marine environments without deteriorating, making them a preferred choice for boat manufacturers.

3. Versatility in Design

Round aluminum extrusion profiles offer significant design flexibility. They can be produced in various diameters and wall thicknesses, allowing for customization to meet specific project requirements. Additionally, the extrusion process enables the creation of complex shapes and features, such as grooves or channels, which can enhance functionality and aesthetics. Designers can leverage this versatility to create innovative products that stand out in the market, whether in architectural applications or consumer goods.

4. Cost-Effectiveness

The aluminum extrusion process is highly efficient, allowing for mass production of profiles at a relatively low cost. The ability to produce long lengths of material with minimal waste contributes to cost savings for manufacturers and end-users alike. Furthermore, the lightweight nature of aluminum can lead to reduced shipping and handling costs, making it an economical choice for various applications. In construction, for example, using aluminum profiles can lower overall project costs due to their ease of installation and reduced labor requirements.

5. Excellent Thermal Conductivity

Aluminum is an excellent conductor of heat, making round aluminum extrusion profiles ideal for applications requiring efficient heat dissipation. This property is particularly valuable in the electronics and automotive industries, where managing heat is crucial for performance and safety. Round profiles can be designed to maximize surface area, enhancing their thermal management capabilities. For instance, heat sinks made from round aluminum profiles are commonly used in electronic devices to dissipate heat effectively, ensuring optimal performance and longevity.

6. Easy to Fabricate and Assemble

Round aluminum extrusion profiles are easy to work with, allowing for straightforward fabrication and assembly. They can be easily cut, drilled, and machined to meet specific project requirements. This ease of fabrication reduces labor costs and time, making aluminum profiles a practical choice for manufacturers and builders. In construction, for example, aluminum profiles can be quickly assembled into frameworks, reducing project timelines and increasing efficiency.

7. Eco-Friendly Material

Aluminum is a sustainable material that can be recycled without losing its properties. The recycling process requires significantly less energy compared to primary aluminum production, making it an environmentally friendly choice. Using round aluminum extrusion profiles contributes to sustainability efforts, as they can be reused and recycled at the end of their life cycle. Many manufacturers are now focusing on using recycled aluminum in their products, further reducing their environmental impact.

8. Aesthetic Appeal

Round aluminum extrusion profiles can be finished in various ways, including anodizing, painting, or powder coating. These finishing options enhance the aesthetic appeal of the profiles, making them suitable for architectural applications, consumer products, and decorative elements. The ability to customize the appearance of aluminum profiles allows designers to create visually appealing products that meet branding and design requirements. For example, anodized aluminum profiles can be produced in a range of colors, allowing for creative design possibilities in modern architecture.

9. High Strength and Durability

Round aluminum extrusion profiles exhibit high strength and durability, making them suitable for demanding applications. The structural integrity of aluminum allows it to withstand significant loads and stresses, ensuring that products maintain their shape and functionality over time. This strength is particularly important in construction and industrial applications, where safety and reliability are paramount. For instance, aluminum scaffolding made from round profiles can support heavy loads while remaining lightweight and easy to transport.

10. Wide Range of Applications

Round aluminum extrusion profiles are used in various industries, including:

- Construction: Used in window frames, curtain walls, and structural components. The lightweight nature of aluminum allows for easier installation and reduced labor costs.

- Automotive: Employed in vehicle frames, heat exchangers, and decorative trim. The corrosion resistance of aluminum makes it ideal for automotive applications exposed to harsh environments.

- Aerospace: Utilized in aircraft components, structural elements, and interior fittings. The high strength-to-weight ratio of aluminum is crucial for aerospace applications.

- Electronics: Used in heat sinks, enclosures, and support structures. The excellent thermal conductivity of aluminum helps manage heat in electronic devices.

- Marine: Employed in boat frames, railings, and other components exposed to harsh environments. Aluminum's corrosion resistance makes it a preferred choice for marine applications.

Conclusion

Round aluminum extrusion profiles offer numerous benefits that make them a popular choice across various industries. Their lightweight nature, corrosion resistance, design versatility, cost-effectiveness, and eco-friendliness contribute to their growing use in modern manufacturing and construction. As industries continue to seek innovative solutions, round aluminum extrusion profiles will undoubtedly play a vital role in shaping the future of design and engineering.

Frequently Asked Questions

1. What are the common applications of round aluminum extrusion profiles?

Round aluminum extrusion profiles are commonly used in construction, automotive, aerospace, electronics, and marine industries for various structural and decorative applications.

2. How does the aluminum extrusion process work?

The aluminum extrusion process involves heating aluminum alloy, forcing it through a die to create a specific shape, cooling it, and then cutting it to the desired length.

3. What are the advantages of using aluminum over other materials?

Aluminum offers a high strength-to-weight ratio, excellent corrosion resistance, thermal conductivity, and is eco-friendly due to its recyclability.

4. Can round aluminum extrusion profiles be customized?

Yes, round aluminum extrusion profiles can be customized in terms of diameter, wall thickness, and surface finish to meet specific project requirements.

5. Is aluminum extrusion cost-effective?

Yes, the aluminum extrusion process is efficient and allows for mass production, resulting in lower costs for manufacturers and end-users.