Content Menu

● Introduction

● Benefits of Hydro Aluminum Profiles

>> Lightweight Yet Strong

>> Corrosion Resistance

>> Design Flexibility

>> Sustainability

>> Thermal Efficiency

>> Aesthetic Appeal

● The Aluminum Extrusion Process

● Custom Aluminum Extrusions

>> Case Studies

● Aluminum Extrusion Alloys

>> Common Alloys Used in Construction

>> Alloy Selection Considerations

● Applications of Aluminum Extrusions

>> Windows and Doors

>> Curtain Walls

>> Structural Components

>> Interior Applications

● Industry Trends and Future Outlook

>> Increased Demand for Sustainable Solutions

>> Innovations in Design and Technology

>> Focus on Energy Efficiency

>> Customization and Personalization

● Conclusion

● Related Questions

>> 1. What are the main advantages of using aluminum profiles in construction?

>> 2. How does the aluminum extrusion process work?

>> 3. What types of aluminum alloys are commonly used in construction?

>> 4. How can Hydro aluminum profiles contribute to sustainability in construction?

>> 5. What are some innovative applications of Hydro aluminum profiles in modern architecture?

Introduction

Aluminum has become a cornerstone material in the construction industry, thanks to its unique properties and versatility. Among the leading providers of aluminum solutions, Hydro stands out with its innovative aluminum extrusion processes. Hydro aluminum profiles are increasingly being utilized in various construction applications, offering numerous benefits that enhance both functionality and aesthetics. This article delves into the key advantages of using Hydro aluminum profiles in construction, exploring their applications, processes, and the future of aluminum in the building sector.

Benefits of Hydro Aluminum Profiles

Hydro aluminum profiles offer a range of benefits that make them an ideal choice for construction projects. These advantages include:

Lightweight Yet Strong

One of the most significant benefits of Hydro aluminum profiles is their lightweight nature combined with high strength. Aluminum is approximately one-third the weight of steel, making it easier to handle and install. This lightweight characteristic reduces transportation costs and allows for quicker assembly on-site. Despite being lightweight, aluminum profiles maintain excellent structural integrity, making them suitable for various load-bearing applications.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, which makes Hydro aluminum profiles highly resistant to corrosion. This property is particularly advantageous in construction, where materials are often exposed to harsh weather conditions. The longevity of aluminum profiles reduces maintenance costs and ensures that structures remain visually appealing over time.

Design Flexibility

Hydro aluminum extrusion allows for a high degree of design flexibility. The extrusion process enables the creation of complex shapes and profiles that can be tailored to meet specific architectural requirements. This versatility allows architects and designers to explore innovative designs without compromising on structural performance. Hydro offers a wide range of standard profiles and can also create custom solutions to meet unique project needs.

Sustainability

Sustainability is a growing concern in the construction industry, and Hydro aluminum profiles contribute positively to this trend. Aluminum is 100% recyclable without losing its properties, making it an environmentally friendly choice. Hydro is committed to sustainable practices, utilizing renewable energy sources in its production processes and promoting recycling initiatives. By choosing Hydro aluminum profiles, construction projects can significantly reduce their carbon footprint.

Thermal Efficiency

Hydro aluminum profiles can be designed to enhance thermal efficiency in buildings. The use of thermal breaks in aluminum windows and doors minimizes heat transfer, improving energy efficiency. This feature is crucial in modern construction, where energy conservation is a priority. By incorporating Hydro aluminum profiles, builders can create structures that meet stringent energy codes and provide comfortable living environments.

Aesthetic Appeal

In addition to their functional benefits, Hydro aluminum profiles offer aesthetic advantages. The sleek, modern appearance of aluminum enhances the visual appeal of buildings. Hydro provides a variety of finishes, including anodized and powder-coated options, allowing for customization that aligns with the overall design vision. This aesthetic versatility makes aluminum profiles suitable for both contemporary and traditional architectural styles.

The Aluminum Extrusion Process

Understanding the aluminum extrusion process is essential to appreciate the benefits of Hydro aluminum profiles fully. The process involves several key steps:

1. Billet Preparation: The process begins with the preparation of aluminum billets, which are cylindrical blocks of aluminum alloy. These billets are heated to a specific temperature to make them malleable.

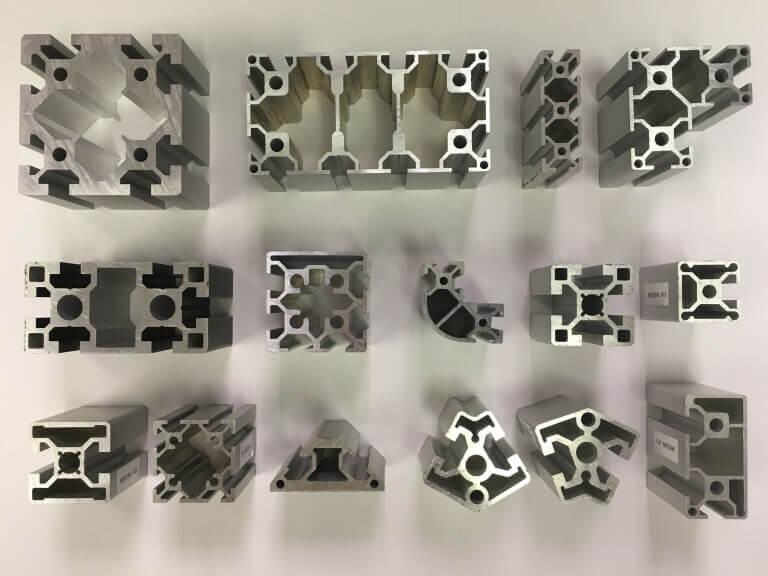

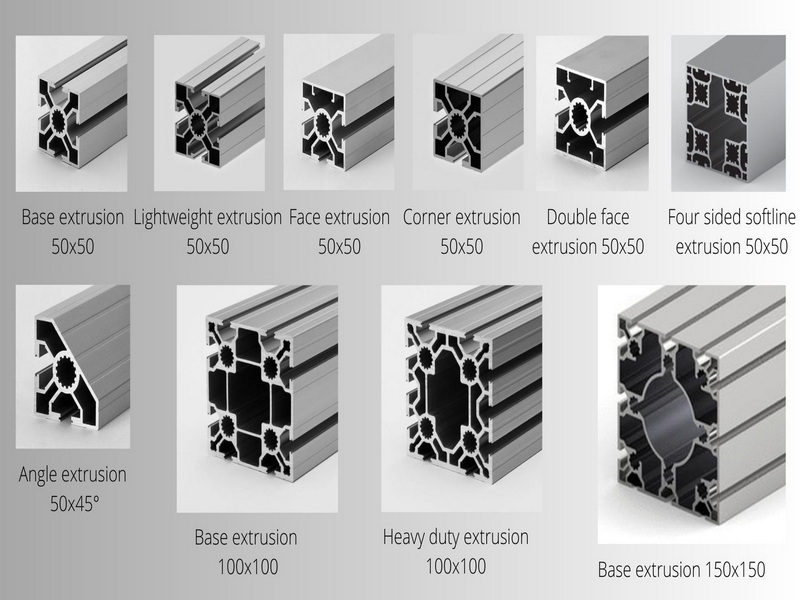

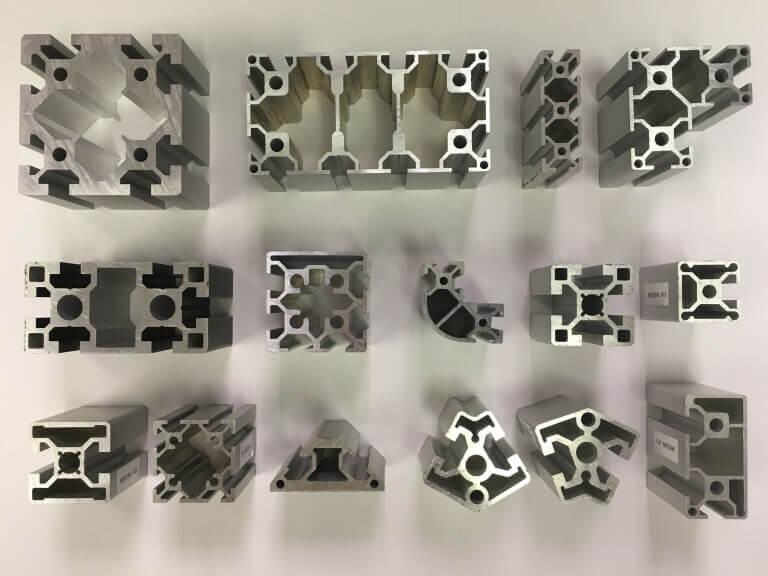

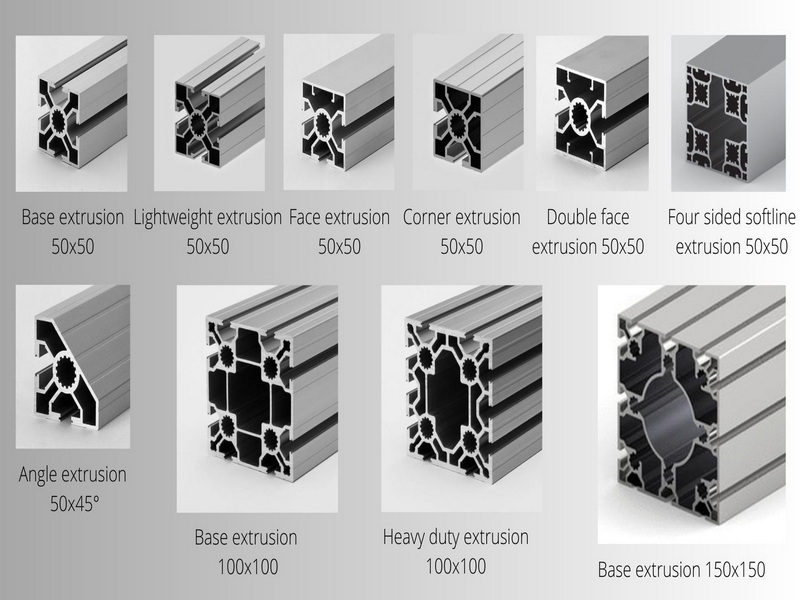

2. Extrusion: The heated billet is then placed in an extrusion press, where it is forced through a die. This die shapes the aluminum into the desired profile. The extrusion process can create a wide variety of shapes, from simple to complex designs.

3. Cooling: After extrusion, the profiles are cooled, typically using air or water. This cooling process solidifies the aluminum and helps maintain its shape.

4. Cutting and Finishing: Once cooled, the extruded profiles are cut to the required lengths. Additional finishing processes, such as anodizing or powder coating, can be applied to enhance the surface properties and aesthetics of the profiles.

5. Quality Control: Hydro places a strong emphasis on quality control throughout the extrusion process. Each profile undergoes rigorous testing to ensure it meets industry standards and customer specifications.

Custom Aluminum Extrusions

Hydro excels in providing custom aluminum extrusions tailored to specific project requirements. This capability is particularly beneficial for construction projects that demand unique solutions. Custom extrusions can be designed to accommodate various functions, such as structural support, thermal performance, and aesthetic considerations.

Case Studies

Several successful projects highlight the advantages of using Hydro custom aluminum extrusions:

- High-Rise Buildings: In urban environments, high-rise buildings often require innovative solutions to maximize space and enhance energy efficiency. Hydro aluminum profiles have been used in curtain wall systems, providing both structural support and aesthetic appeal.

- Residential Projects: Custom aluminum extrusions have been employed in residential construction, particularly in window and door systems. These profiles offer excellent thermal performance while allowing for sleek, modern designs.

- Commercial Spaces: In commercial construction, Hydro aluminum profiles are utilized in various applications, including storefronts and interior partitions. The versatility of aluminum allows for creative designs that enhance the overall functionality of the space.

Aluminum Extrusion Alloys

The choice of aluminum alloy is crucial in determining the performance characteristics of the extruded profiles. Hydro offers a range of aluminum alloys, each with unique properties suited for different applications.

Common Alloys Used in Construction

- 6061 Alloy: Known for its excellent mechanical properties and corrosion resistance, 6061 is widely used in structural applications, including beams and frames.

- 6063 Alloy: This alloy is favored for architectural applications due to its smooth surface finish and good extrudability. It is commonly used in window frames and decorative elements.

- 7005 Alloy: Often used in applications requiring high strength-to-weight ratios, 7005 is ideal for structural components in buildings.

Alloy Selection Considerations

When selecting an aluminum alloy for construction, several factors should be considered, including:

- Strength Requirements: The load-bearing capacity of the profile must align with the structural demands of the project.

- Corrosion Resistance: Depending on the environmental conditions, the alloy's resistance to corrosion may be a critical factor.

- Aesthetic Preferences: The chosen alloy should also accommodate the desired finish and appearance of the final product.

Applications of Aluminum Extrusions

Hydro aluminum profiles find applications across various sectors within the construction industry. Some notable applications include:

Windows and Doors

Aluminum profiles are commonly used in window and door systems due to their strength, durability, and thermal efficiency. Hydro's profiles can be designed to meet specific energy performance standards, making them ideal for residential and commercial buildings.

Curtain Walls

In high-rise buildings, curtain walls made from Hydro aluminum profiles provide an attractive façade while allowing natural light to penetrate the interior spaces. These systems are designed to withstand wind loads and thermal expansion, ensuring long-term performance.

Structural Components

Aluminum extrusions are increasingly being used as structural components in buildings. Their lightweight nature reduces the overall weight of the structure, while their strength ensures safety and stability.

Interior Applications

Hydro aluminum profiles are also utilized in interior applications, such as partitions, handrails, and ceiling systems. The versatility of aluminum allows for creative designs that enhance the functionality and aesthetics of interior spaces.

Industry Trends and Future Outlook

The aluminum extrusion industry is evolving, driven by technological advancements and changing market demands. Some key trends shaping the future of Hydro aluminum profiles in construction include:

Increased Demand for Sustainable Solutions

As sustainability becomes a priority in construction, the demand for eco-friendly materials is on the rise. Hydro's commitment to using renewable energy and promoting recycling aligns with this trend, positioning the company as a leader in sustainable aluminum solutions.

Innovations in Design and Technology

Advancements in design software and manufacturing technologies are enabling more complex and efficient aluminum profiles. Hydro is at the forefront of these innovations, continuously improving its extrusion processes to meet the evolving needs of the construction industry.

Focus on Energy Efficiency

With stricter energy codes being implemented globally, the focus on energy-efficient building materials is intensifying. Hydro aluminum profiles, with their thermal performance capabilities, are well-positioned to meet these demands.

Customization and Personalization

As construction projects become more specialized, the need for customized solutions is growing. Hydro's ability to provide tailored aluminum extrusions allows architects and builders to create unique designs that stand out in the market.

Conclusion

Hydro aluminum profiles offer a multitude of benefits that make them an excellent choice for construction projects. From their lightweight and corrosion-resistant properties to their design flexibility and sustainability, these profiles enhance both the functionality and aesthetics of buildings. As the construction industry continues to evolve, Hydro remains committed to providing innovative aluminum solutions that meet the demands of modern architecture.

Related Questions

1. What are the main advantages of using aluminum profiles in construction?

Aluminum profiles are lightweight, corrosion-resistant, and offer design flexibility, making them ideal for various construction applications.

2. How does the aluminum extrusion process work?

The aluminum extrusion process involves heating aluminum billets, forcing them through a die to create profiles, cooling them, and then cutting and finishing the profiles.

3. What types of aluminum alloys are commonly used in construction?

Common aluminum alloys used in construction include 6061, 6063, and 7005, each with unique properties suited for different applications.

4. How can Hydro aluminum profiles contribute to sustainability in construction?

Hydro aluminum profiles are 100% recyclable and produced using renewable energy, helping to reduce the carbon footprint of construction projects.

5. What are some innovative applications of Hydro aluminum profiles in modern architecture?

Hydro aluminum profiles are used in high-rise buildings, residential projects, and commercial spaces, providing structural support, thermal efficiency, and aesthetic appeal.