Content Menu

● Introduction

● Understanding Aluminum Extrusion

● Key Benefits of Aluminum Extrusion Profiles

>> Lightweight and Strong

>> Versatility in Design

>> Corrosion Resistance

>> Cost-Effectiveness

● Applications in Construction

● Conclusion

● Related Questions

>> 1. What are the environmental benefits of using aluminum extrusion profiles in construction?

>> 2. How do aluminum extrusion profiles compare to other materials in terms of thermal performance?

>> 3. Can aluminum extrusion shapes be used in high-rise buildings?

>> 4. What maintenance is required for aluminum extrusion profiles?

>> 5. Are custom aluminum extrusion shapes more expensive than standard profiles?

Introduction

Aluminum extrusion profiles have become a cornerstone in modern construction, offering a unique combination of strength, versatility, and cost-effectiveness. As the construction industry continues to evolve, the demand for materials that can meet both aesthetic and functional requirements has never been higher. Aluminum extrusion shapes are not only lightweight but also provide exceptional durability, making them an ideal choice for a wide range of applications. This article delves into the key benefits of using aluminum extrusion profiles in construction, exploring their properties, applications, and the reasons behind their growing popularity.

Understanding Aluminum Extrusion

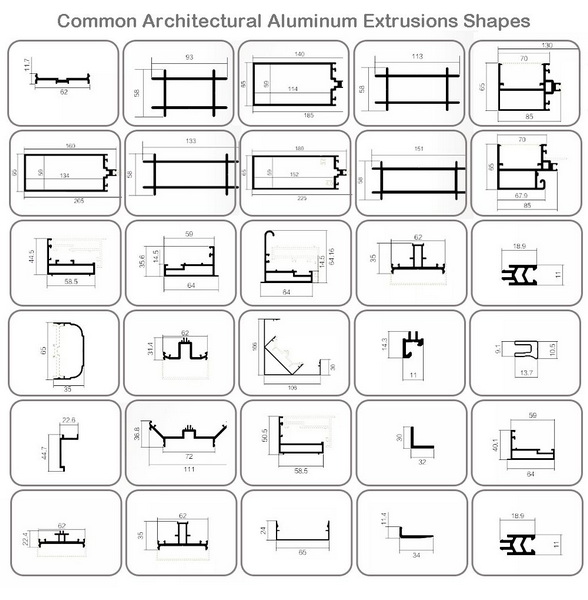

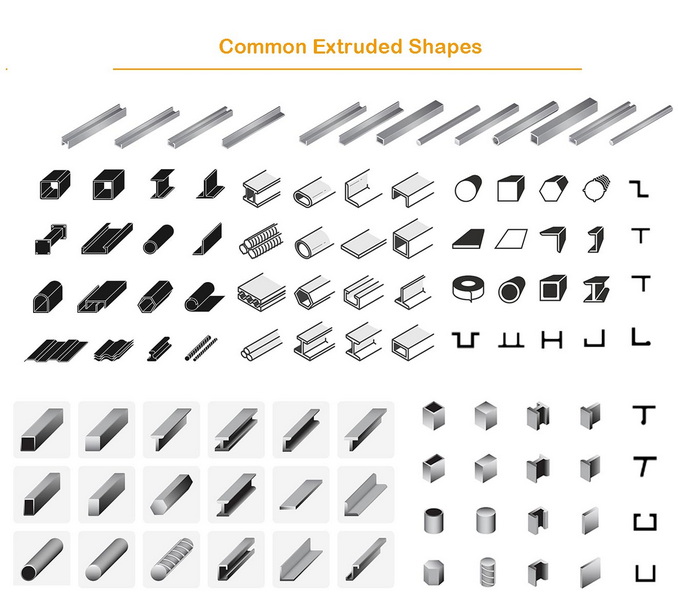

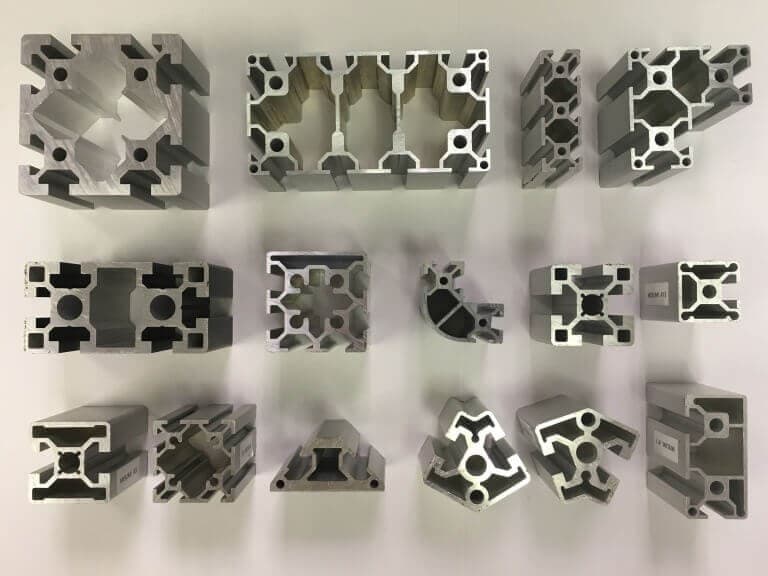

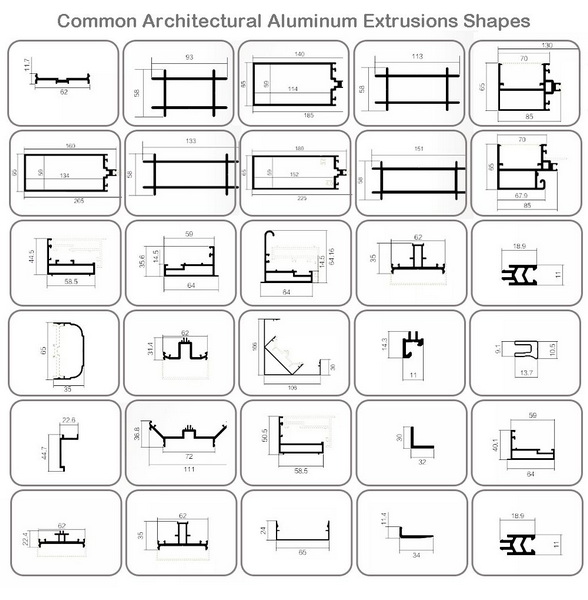

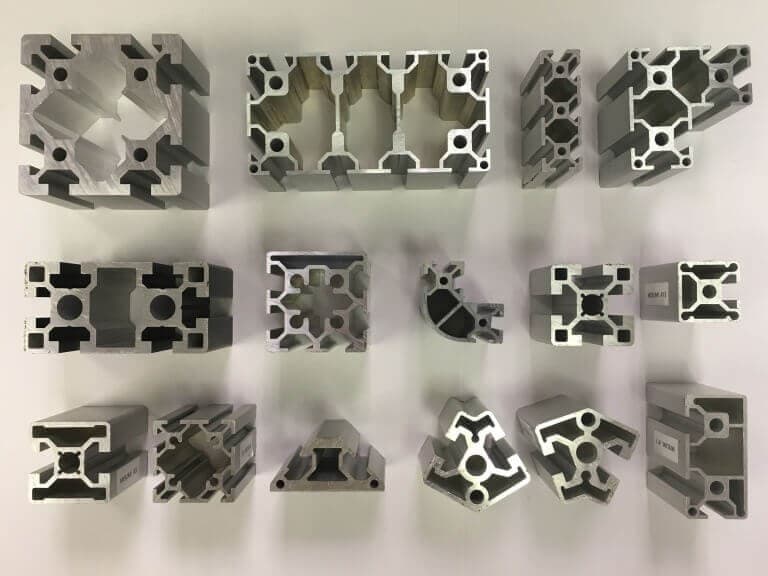

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy into a desired cross-sectional profile. This is achieved by forcing heated aluminum through a die, which gives it the desired shape. The process allows for the creation of complex shapes that would be difficult or impossible to achieve with other manufacturing methods.

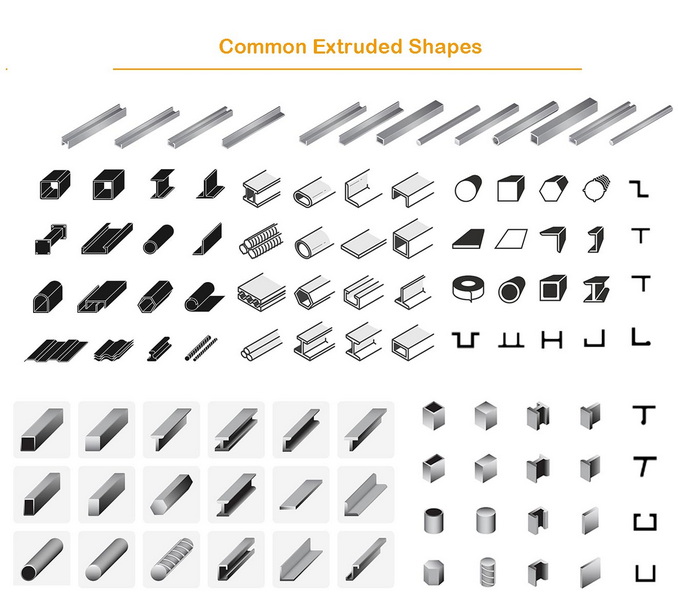

Aluminum extrusion profiles come in various forms, including standard shapes like angles, channels, and tubes, as well as custom designs tailored to specific project needs. The versatility of aluminum extrusion shapes makes them suitable for a wide range of applications, from structural components to decorative elements.

Key Benefits of Aluminum Extrusion Profiles

Lightweight and Strong

One of the most significant advantages of aluminum extrusion profiles is their lightweight nature combined with high strength. Aluminum has a remarkable strength-to-weight ratio, making it an ideal material for construction. This characteristic allows for easier handling and installation, reducing labor costs and time on site.

For instance, when used in structural applications, aluminum extrusion shapes can support substantial loads while remaining significantly lighter than traditional materials like steel or concrete. This property is particularly beneficial in high-rise buildings, where reducing the overall weight of the structure can lead to lower foundation costs and improved seismic performance.

Versatility in Design

Aluminum extrusion profiles offer unparalleled versatility in design. The extrusion process allows for the creation of intricate shapes and designs that can be customized to meet specific project requirements. Architects and designers can take advantage of this flexibility to create unique and aesthetically pleasing structures.

Custom aluminum extrusions can be designed to fit specific applications, whether it's for window frames, curtain walls, or decorative elements. The ability to produce complex shapes means that designers can push the boundaries of creativity while ensuring that the final product meets functional requirements.

Corrosion Resistance

Aluminum is naturally resistant to corrosion, thanks to a protective oxide layer that forms on its surface when exposed to air. This characteristic makes aluminum extrusion profiles an excellent choice for construction projects in harsh environments, such as coastal areas or regions with high humidity.

The corrosion resistance of aluminum means that structures can maintain their appearance and structural integrity over time, reducing the need for maintenance and replacement. This durability is particularly important for applications such as outdoor furniture, railings, and cladding, where exposure to the elements is a concern.

Cost-Effectiveness

When considering the overall lifecycle costs of construction materials, aluminum extrusion profiles often prove to be a cost-effective option. While the initial material cost may be higher than some alternatives, the long-term savings associated with reduced maintenance, lower energy consumption, and extended lifespan can outweigh these initial expenses.

Additionally, the lightweight nature of aluminum extrusion shapes can lead to savings in transportation and installation costs. The ease of handling and installation reduces labor time, further contributing to overall project savings.

Applications in Construction

Aluminum extrusion profiles are used in a wide variety of construction applications, showcasing their versatility and adaptability. Some common applications include:

- Window Frames: Aluminum extrusion shapes are widely used for window frames due to their strength, durability, and aesthetic appeal. They can be designed to accommodate various glazing options and provide excellent thermal performance.

- Structural Components: In commercial and residential buildings, aluminum extrusions are often used for structural elements such as beams, columns, and trusses. Their lightweight nature allows for efficient designs that do not compromise on strength.

- Curtain Walls: Aluminum extrusion profiles are a popular choice for curtain wall systems, providing a sleek and modern appearance while allowing for large expanses of glass. This application enhances natural light and improves energy efficiency.

- Railings and Fencing: The corrosion resistance of aluminum makes it an ideal material for railings and fencing, particularly in outdoor settings. Aluminum extrusion shapes can be designed to meet safety standards while providing an attractive finish.

- Decorative Elements: Architects often use aluminum extrusion profiles for decorative features, such as canopies, sunshades, and architectural accents. The ability to create custom shapes allows for unique design solutions that enhance the overall aesthetic of a building.

Conclusion

In conclusion, aluminum extrusion profiles offer a multitude of benefits that make them an ideal choice for construction projects. Their lightweight and strong nature, versatility in design, corrosion resistance, and cost-effectiveness contribute to their growing popularity in the industry. As architects and builders continue to seek innovative solutions that meet both functional and aesthetic requirements, aluminum extrusion shapes will undoubtedly play a crucial role in the future of construction.

Related Questions

1. What are the environmental benefits of using aluminum extrusion profiles in construction?

Aluminum is a highly recyclable material, and using aluminum extrusion profiles can contribute to sustainable building practices. The recycling process requires only a fraction of the energy needed to produce new aluminum, reducing the overall carbon footprint of construction projects.

2. How do aluminum extrusion profiles compare to other materials in terms of thermal performance?

Aluminum extrusion profiles can be designed with thermal breaks to improve energy efficiency. This feature helps to minimize heat transfer, making them suitable for energy-efficient building designs compared to traditional materials.

3. Can aluminum extrusion shapes be used in high-rise buildings?

Yes, aluminum extrusion profiles are commonly used in high-rise buildings due to their lightweight nature and high strength. They can support significant loads while reducing the overall weight of the structure, which is crucial for tall buildings.

4. What maintenance is required for aluminum extrusion profiles?

Aluminum extrusion profiles require minimal maintenance due to their corrosion resistance. Regular cleaning to remove dirt and debris is usually sufficient to maintain their appearance and performance.

5. Are custom aluminum extrusion shapes more expensive than standard profiles?

While custom aluminum extrusion shapes may have a higher initial cost due to the design and manufacturing process, the long-term benefits, such as improved performance and reduced maintenance, often justify the investment.