Content Menu

● Introduction

● Understanding 8080 Aluminum Profiles

● Benefits of Using 8080 Aluminum Profiles

>> Strength and Durability

>> Lightweight Nature

>> Corrosion Resistance

>> Versatility in Design

>> Cost-Effectiveness

● Conclusion

● Related Questions

>> 1. What are the main applications of 8080 aluminum profiles in construction?

>> 2. How does the T-slot design of 8080 aluminum profiles enhance their usability?

>> 3. Are 8080 aluminum profiles suitable for outdoor use?

>> 4. How do 8080 aluminum profiles compare to steel in terms of weight and strength?

>> 5. What factors should be considered when choosing aluminum profiles for a construction project?

Introduction

Aluminum extrusion has become a cornerstone in modern construction, offering a blend of strength, versatility, and lightweight properties that traditional materials often cannot match. Among the various profiles available, the 8080 aluminum profile stands out due to its unique specifications and applications. This article delves into the key benefits of using 8080 aluminum profiles in construction, exploring their structural integrity, lightweight nature, corrosion resistance, design versatility, and cost-effectiveness.

Understanding 8080 Aluminum Profiles

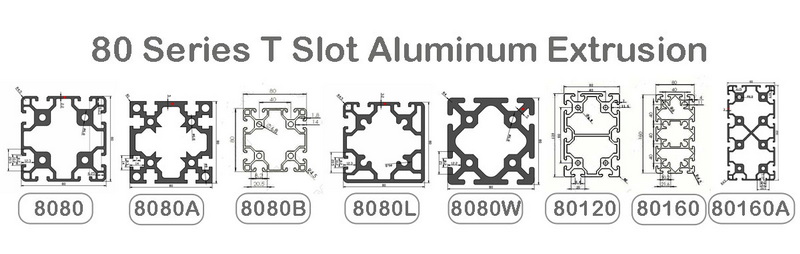

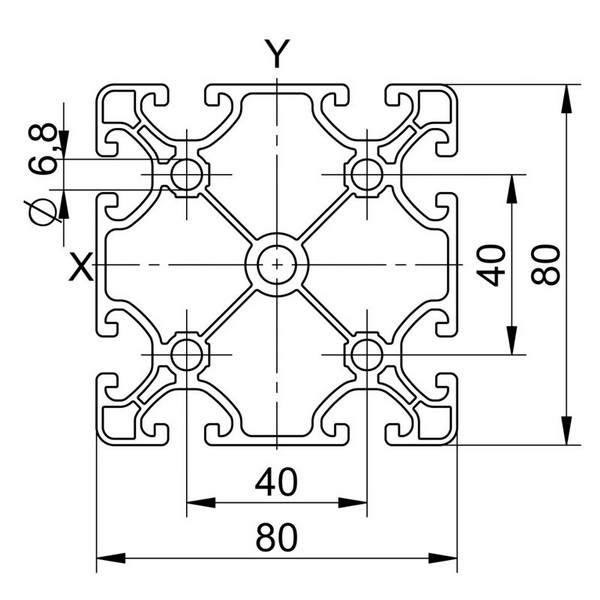

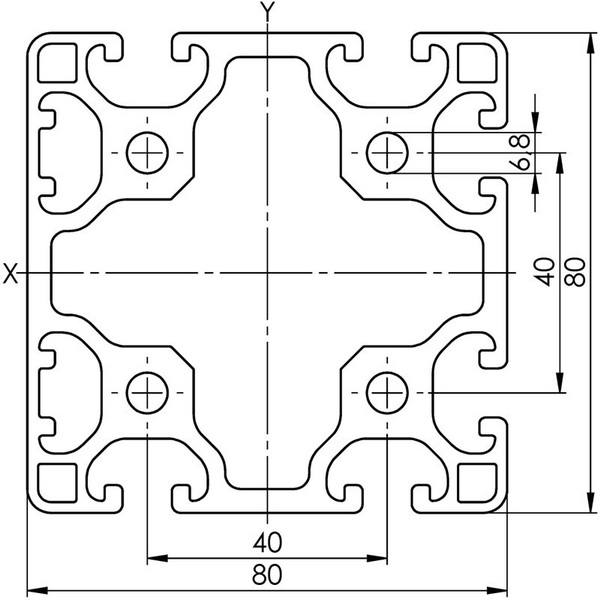

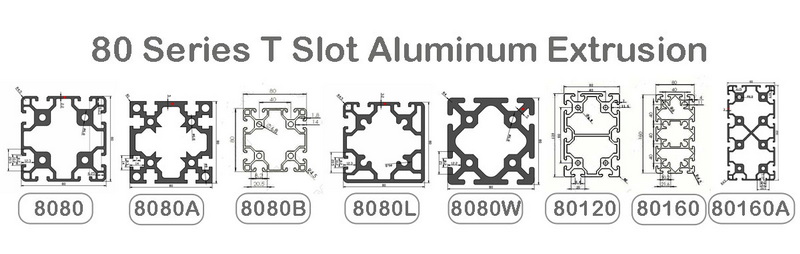

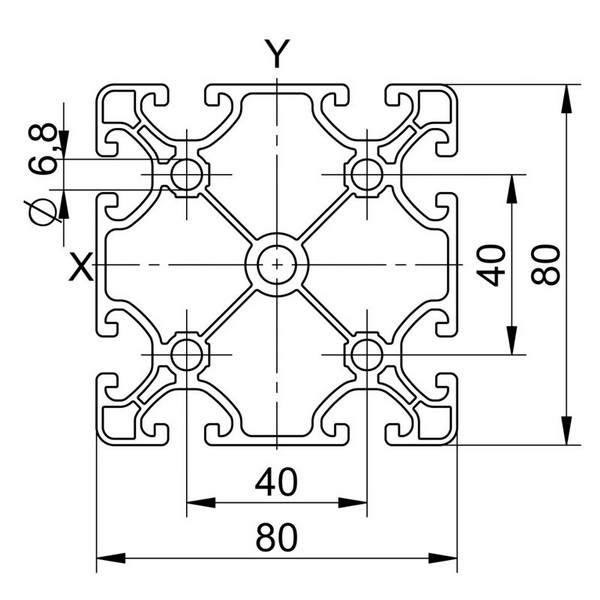

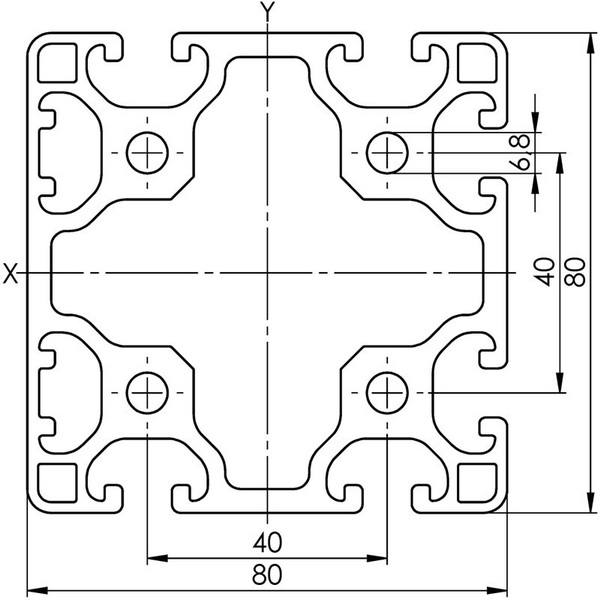

The 8080 aluminum profile is part of the 80 series of aluminum extrusions, characterized by its dimensions of 80mm x 80mm. This profile is designed with a T-slot configuration, allowing for easy assembly and integration into various structures. The T-slot design enables the attachment of other components without the need for additional hardware, making it a favorite among engineers and designers.

The 8080 profile is often used in applications that require robust structural support, such as frames for machinery, workstations, and even architectural elements. Its compatibility with other 80 series profiles enhances its versatility, allowing for a wide range of configurations and designs.

Benefits of Using 8080 Aluminum Profiles

Strength and Durability

One of the primary advantages of 8080 aluminum profiles is their exceptional strength and durability. Aluminum, as a material, is known for its high strength-to-weight ratio, making it ideal for construction applications where structural integrity is paramount. The 8080 profile can withstand significant loads, making it suitable for heavy-duty applications.

For instance, in industrial settings, 8080 aluminum profiles are often used to create frames for machinery and equipment. Their ability to support heavy weights without bending or warping ensures that structures remain stable and safe over time. Additionally, aluminum's inherent resistance to rust and corrosion further enhances the longevity of these profiles, reducing the need for frequent replacements or repairs.

Lightweight Nature

Another significant benefit of 8080 aluminum profiles is their lightweight nature. Compared to traditional materials like steel or wood, aluminum is considerably lighter, which translates to easier handling and installation. This characteristic is particularly advantageous in construction projects where time and labor costs are critical factors.

The lightweight nature of 8080 aluminum profiles also contributes to lower transportation costs. When transporting materials to a construction site, the reduced weight can lead to savings in fuel and logistics. Moreover, lighter materials can simplify the design of supporting structures, allowing for more innovative architectural solutions.

Corrosion Resistance

Aluminum is naturally resistant to corrosion, thanks to a protective oxide layer that forms on its surface when exposed to air. This property is especially beneficial in construction, where materials are often subjected to harsh environmental conditions. The 8080 aluminum profile's corrosion resistance makes it an ideal choice for outdoor applications, such as in the construction of pergolas, canopies, and other structures exposed to the elements.

In addition to outdoor use, the corrosion resistance of 8080 aluminum profiles is advantageous in industrial environments where exposure to chemicals and moisture is common. By using aluminum profiles, builders can ensure that their structures maintain their integrity and appearance over time, reducing maintenance costs and extending the lifespan of the construction.

Versatility in Design

The design versatility of 8080 aluminum profiles is one of their most appealing features. The T-slot design allows for easy customization and modification, enabling builders to create complex structures with relative ease. This flexibility is particularly valuable in modular construction, where components can be reconfigured or expanded as needed.

For example, in the creation of workstations or assembly lines, 8080 aluminum profiles can be used to build adjustable frames that accommodate different equipment layouts. This adaptability not only enhances functionality but also allows for efficient use of space in manufacturing and industrial settings.

Moreover, the aesthetic appeal of aluminum profiles can enhance the overall look of a construction project. The sleek, modern appearance of 8080 aluminum profiles can complement various architectural styles, making them a popular choice for both commercial and residential applications.

Cost-Effectiveness

When considering the overall cost of construction materials, 8080 aluminum profiles offer significant long-term savings. While the initial investment may be higher than some traditional materials, the durability and low maintenance requirements of aluminum profiles lead to reduced costs over time.

The lightweight nature of 8080 aluminum profiles also contributes to cost savings during installation. With easier handling and faster assembly, labor costs can be minimized, allowing projects to be completed more efficiently. Additionally, the corrosion resistance of aluminum reduces the need for protective coatings or treatments, further lowering maintenance expenses.

In summary, the cost-effectiveness of 8080 aluminum profiles makes them an attractive option for builders looking to balance quality and budget.

Conclusion

In conclusion, the 8080 aluminum profile offers a multitude of benefits that make it an excellent choice for construction projects. Its strength and durability ensure structural integrity, while its lightweight nature facilitates easier handling and installation. The corrosion resistance of aluminum enhances the longevity of structures, and the design versatility allows for innovative solutions in various applications. Finally, the cost-effectiveness of 8080 aluminum profiles makes them a smart investment for builders and contractors alike.

As the construction industry continues to evolve, the demand for materials that combine performance, aesthetics, and sustainability will only grow. The 8080 aluminum profile stands out as a prime example of how modern materials can meet these demands, paving the way for future innovations in construction.

Related Questions

1. What are the main applications of 8080 aluminum profiles in construction?

The main applications of 8080 aluminum profiles include creating frames for machinery, workstations, modular structures, and architectural elements such as canopies and pergolas.

2. How does the T-slot design of 8080 aluminum profiles enhance their usability?

The T-slot design allows for easy assembly and integration of various components without the need for additional hardware, making it simple to customize and modify structures.

3. Are 8080 aluminum profiles suitable for outdoor use?

Yes, 8080 aluminum profiles are highly suitable for outdoor use due to their natural corrosion resistance, making them ideal for structures exposed to the elements.

4. How do 8080 aluminum profiles compare to steel in terms of weight and strength?

While steel is generally stronger, 8080 aluminum profiles offer a high strength-to-weight ratio, making them lighter and easier to handle, which can be advantageous in many construction applications.

5. What factors should be considered when choosing aluminum profiles for a construction project?

Factors to consider include the specific application requirements, load-bearing capacity, environmental conditions, design flexibility, and overall cost-effectiveness.