Content Menu

● Introduction

● Understanding 4080 Aluminum Extrusion

● Benefits of Using 4080 Aluminum Extrusion

>> Versatility

>> Strength and Durability

>> Ease of Assembly

>> Common Applications of 4080 Aluminum Extrusion

● Choosing the Right 4080 Aluminum Profile

● Conclusion

● Related Questions

>> 1. What industries commonly use 4080 aluminum extrusion?

>> 2. How does the T-slot design benefit assembly?

>> 3. Can 4080 aluminum extrusion be used outdoors?

>> 4. What are the load capacities of 4080 aluminum extrusion?

>> 5. How can I customize 4080 aluminum extrusion for my project?

Introduction

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This technique is widely used across various industries due to its versatility, strength, and lightweight properties. Among the many profiles available, the 4080 aluminum extrusion stands out for its unique features and applications. This article explores the key benefits of using 4080 aluminum extrusion in your projects, highlighting its versatility, strength, ease of assembly, and common applications.

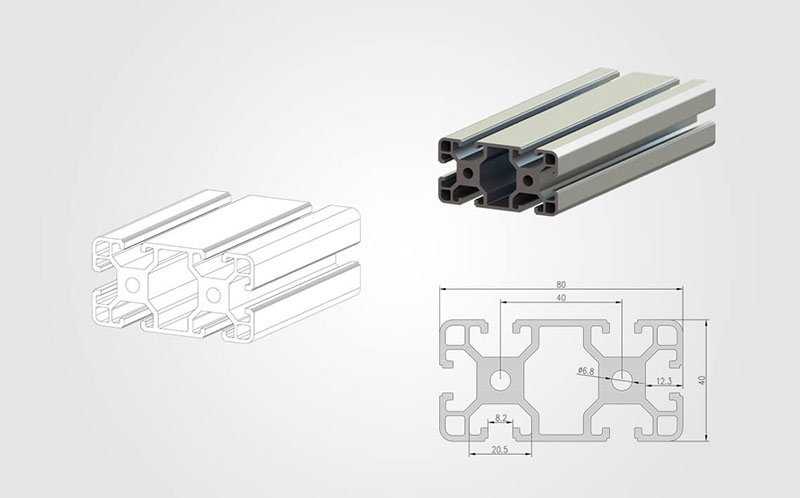

Understanding 4080 Aluminum Extrusion

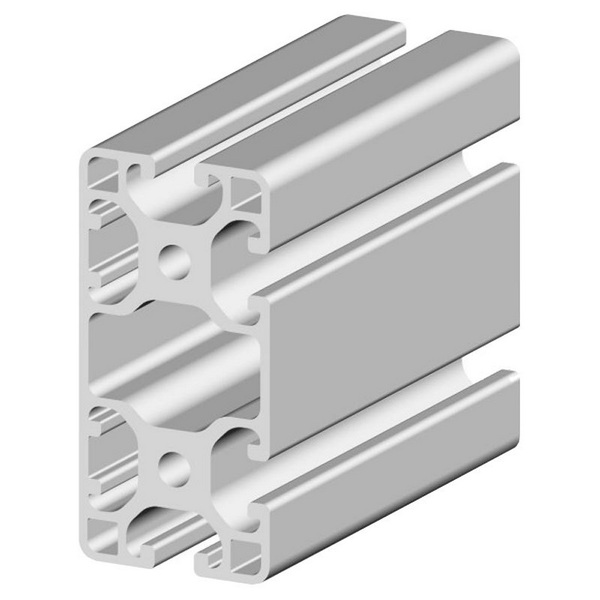

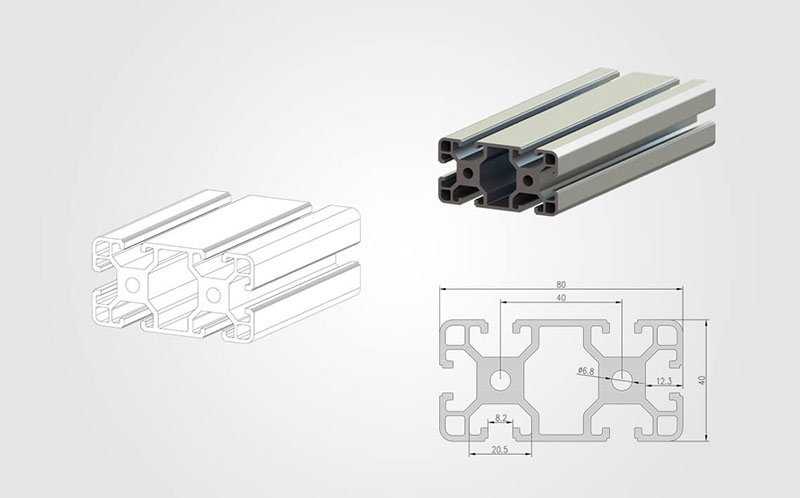

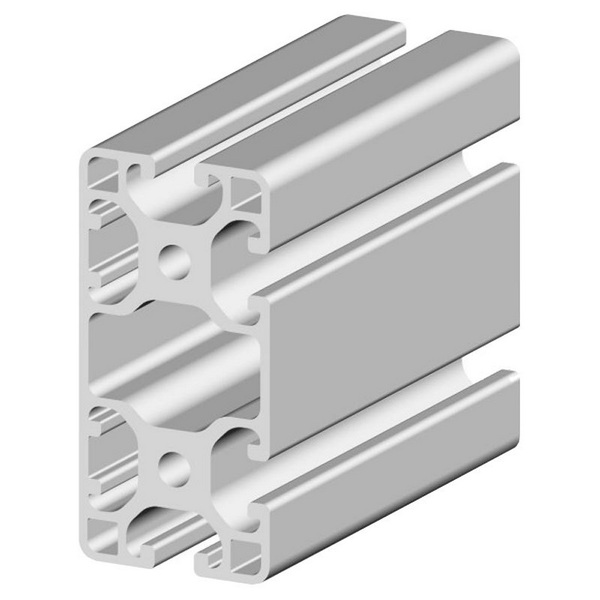

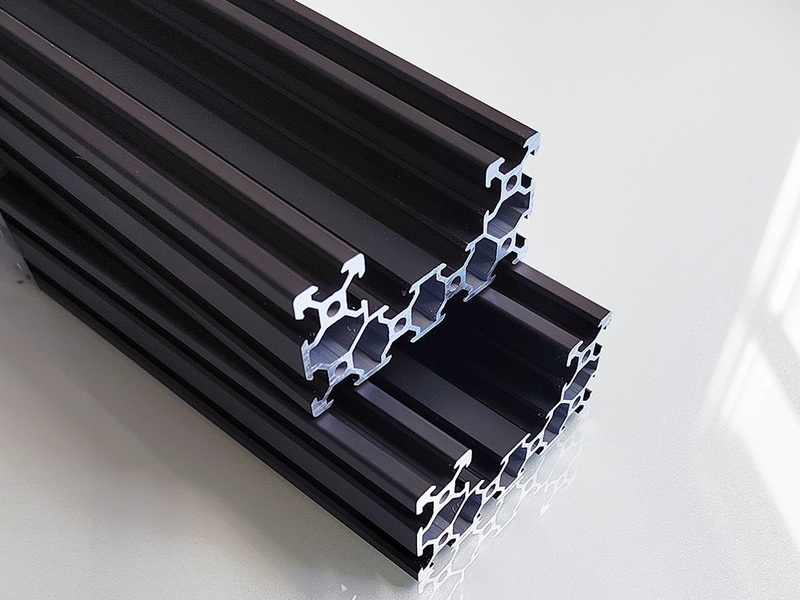

The 4080 aluminum extrusion profile is characterized by its dimensions, which measure 40mm by 80mm. This profile is part of the T-slot aluminum extrusion family, which allows for easy assembly and customization. The T-slot design features grooves along the length of the profile, enabling the attachment of various components without the need for additional hardware.

One of the significant advantages of the 4080 profile is its compatibility with other aluminum extrusions, making it an ideal choice for modular construction. This flexibility allows engineers and designers to create complex structures with relative ease.

Benefits of Using 4080 Aluminum Extrusion

Versatility

One of the primary benefits of 4080 aluminum extrusion is its versatility. This profile can be used in a wide range of applications, from manufacturing and construction to robotics and automation. The ability to customize the profile for specific needs makes it a popular choice among engineers and designers.

For instance, in manufacturing, 4080 aluminum extrusions can be used to create frames for machinery, workstations, and conveyor systems. In construction, they can be utilized for building structures, such as scaffolding and support frames. The adaptability of this profile allows it to fit seamlessly into various projects, regardless of the industry.

Strength and Durability

Another significant advantage of 4080 aluminum extrusion is its strength and durability. Aluminum is known for its excellent strength-to-weight ratio, making it an ideal material for structural applications. The 4080 profile is designed to withstand heavy loads, making it suitable for demanding environments.

The durability of aluminum also means that structures made from 4080 extrusions are resistant to corrosion and wear. This characteristic is particularly beneficial in outdoor applications where exposure to the elements can lead to degradation over time. By using 4080 aluminum extrusion, you can ensure that your projects will stand the test of time.

Ease of Assembly

The T-slot design of 4080 aluminum extrusion significantly simplifies the assembly process. The grooves along the profile allow for easy attachment of brackets, connectors, and other components without the need for drilling or welding. This feature not only saves time during assembly but also reduces the overall cost of the project.

Additionally, the modular nature of the 4080 profile means that components can be easily reconfigured or replaced as needed. This flexibility is particularly advantageous in environments where designs may need to be adjusted or updated frequently.

Common Applications of 4080 Aluminum Extrusion

The versatility and strength of 4080 aluminum extrusion make it suitable for a wide range of applications. Here are some common uses:

- CNC Machines: The 4080 profile is often used in the construction of CNC machines due to its rigidity and ability to support heavy components. The T-slot design allows for easy mounting of motors, rails, and other essential parts.

- Automation Systems: In automation, 4080 aluminum extrusions are used to create frames for robotic arms and conveyor systems. The lightweight nature of aluminum helps improve the efficiency of these systems.

- Framing Systems: The 4080 profile is ideal for building custom framing systems for various projects. Its strength and modularity allow for the creation of robust structures that can be tailored to specific needs.

- Workstations: Many manufacturers use 4080 aluminum extrusion to build ergonomic workstations. The ability to adjust the height and configuration of these workstations enhances productivity and comfort for workers.

Choosing the Right 4080 Aluminum Profile

When selecting the right 4080 aluminum profile for your project, several factors should be considered:

- Load Requirements: Assess the weight and load requirements of your application. The 4080 profile is designed to handle significant loads, but it's essential to ensure it meets your specific needs.

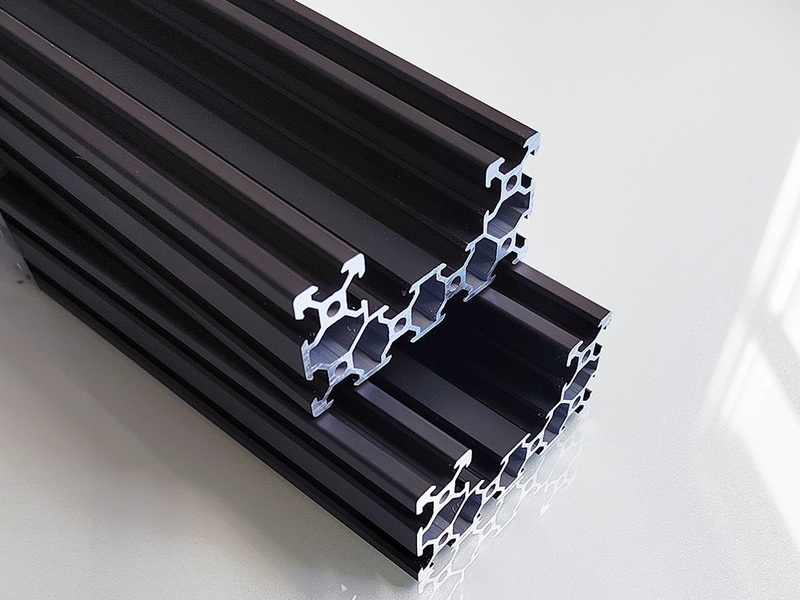

- Environmental Conditions: Consider the environment in which the aluminum extrusion will be used. If the application is outdoors, ensure that the profile is treated to resist corrosion.

- Customization Needs: Determine if you need to customize the profile for your project. The modular nature of 4080 aluminum extrusion allows for easy modifications, so consider how you might need to adapt it in the future.

- Budget: Finally, consider your budget. While aluminum extrusions can be more expensive than other materials, their durability and versatility often justify the investment.

Conclusion

In conclusion, the 4080 aluminum extrusion profile offers numerous benefits that make it an excellent choice for a wide range of projects. Its versatility, strength, ease of assembly, and adaptability to various applications make it a preferred option among engineers and designers. Whether you are working on a manufacturing project, constructing a building, or designing an automation system, the 4080 aluminum extrusion can provide the support and flexibility you need.

By understanding the key benefits and applications of 4080 aluminum extrusion, you can make informed decisions that enhance the quality and efficiency of your projects. As you explore the possibilities of this remarkable material, consider how it can be integrated into your future designs.

Related Questions

1. What industries commonly use 4080 aluminum extrusion?

The 4080 aluminum extrusion is commonly used in manufacturing, construction, robotics, and automation industries due to its versatility and strength.

2. How does the T-slot design benefit assembly?

The T-slot design allows for easy attachment of components without the need for drilling or welding, saving time and reducing costs during assembly.

3. Can 4080 aluminum extrusion be used outdoors?

Yes, 4080 aluminum extrusion is resistant to corrosion, making it suitable for outdoor applications when properly treated.

4. What are the load capacities of 4080 aluminum extrusion?

The load capacities of 4080 aluminum extrusion depend on the specific application and configuration, but it is designed to handle significant loads effectively.

5. How can I customize 4080 aluminum extrusion for my project?

You can customize 4080 aluminum extrusion by using various connectors, brackets, and accessories that fit the T-slot design, allowing for flexible configurations.