Content Menu

● Key Benefits of 4040 Aluminum Extrusions

>> Versatility

>> Strength and Durability

>> Lightweight Nature

● Common Applications of 4040 Aluminum Extrusions

>> Industrial Frameworks

>> DIY Projects

>> Furniture and Displays

● How to Select the Right 4040 Aluminum Profile

>> Understanding Your Project Requirements

>> Sourcing Quality Extrusions

● Conclusion

● Related Questions

>> 1. What are the main advantages of using aluminum extrusions over other materials?

>> 2. Can 4040 aluminum extrusions be used outdoors?

>> 3. How do I cut 4040 aluminum extrusions?

>> 4. Are 4040 aluminum extrusions recyclable?

>> 5. What types of fasteners are compatible with 4040 aluminum extrusions?

Key Benefits of 4040 Aluminum Extrusions

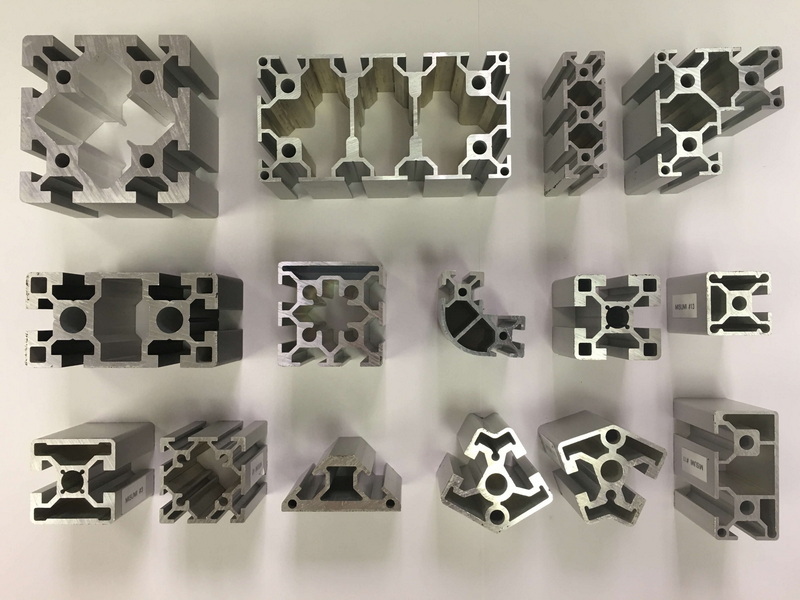

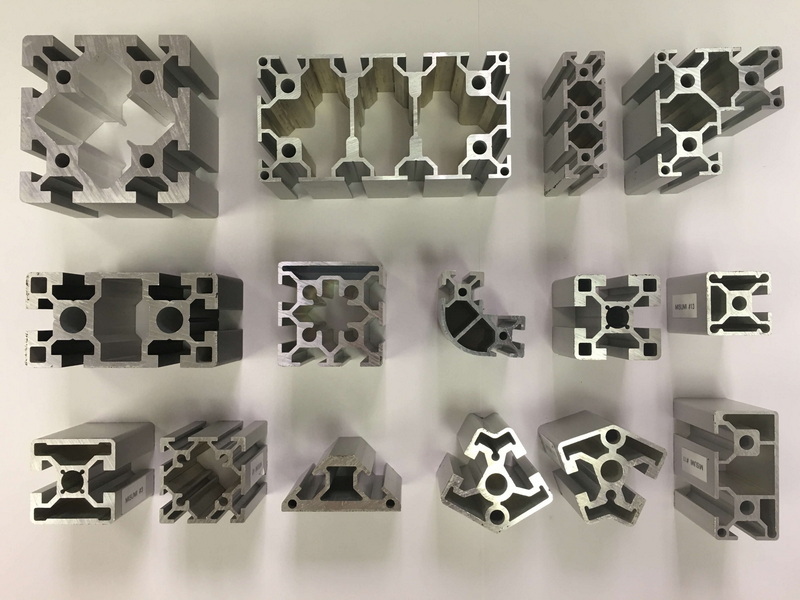

Versatility

One of the most significant advantages of 4040 aluminum extrusions is their versatility. These profiles can be used in a wide range of applications, from industrial frameworks to DIY projects. The T-slot design allows for easy assembly and disassembly, making it ideal for modular construction. Whether you are building a machine frame, a workstation, or a custom display, the 4040 aluminum extrusion can adapt to your needs.

The ability to connect multiple profiles at various angles without the need for specialized tools or fasteners simplifies the construction process. This adaptability is particularly beneficial in environments where modifications and adjustments are frequently required.

Strength and Durability

4040 aluminum extrusions are known for their impressive strength-to-weight ratio. Made from high-quality aluminum alloy, these profiles can withstand significant loads while remaining lightweight. This characteristic is crucial in applications where structural integrity is paramount, such as in automation systems and industrial machinery.

The durability of 4040 aluminum extrusions also means they are resistant to corrosion and wear, making them suitable for both indoor and outdoor use. This longevity reduces the need for frequent replacements, ultimately saving time and money in the long run.

Lightweight Nature

The lightweight nature of 4040 aluminum extrusions is another key benefit. Unlike steel or other heavier materials, aluminum allows for easier handling and transportation. This feature is particularly advantageous in projects where weight is a critical factor, such as in aerospace or automotive applications.

Additionally, the reduced weight of aluminum extrusions can lead to lower shipping costs and easier installation. This aspect is especially beneficial for DIY enthusiasts and small businesses looking to minimize expenses while maximizing efficiency.

Common Applications of 4040 Aluminum Extrusions

Industrial Frameworks

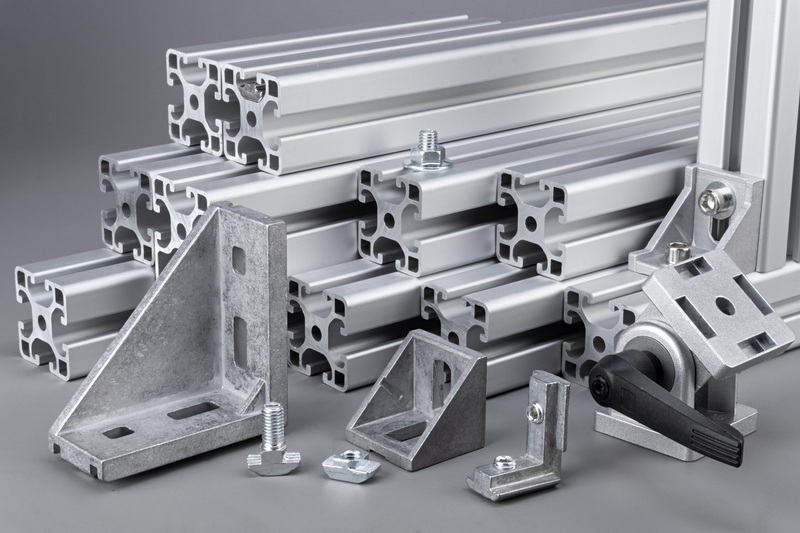

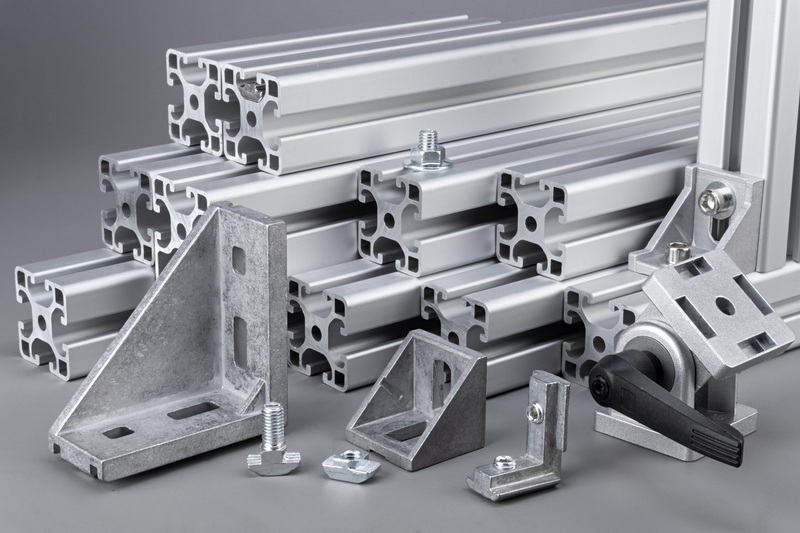

4040 aluminum extrusions are widely used in industrial frameworks due to their strength and versatility. They can be employed to create machine frames, conveyor systems, and workstations. The ability to customize the design and dimensions of the profiles allows engineers to create structures that meet specific requirements.

For instance, in automation systems, 4040 aluminum extrusions can be used to build robust frames that support various components, such as motors, sensors, and control panels. The modular nature of these profiles enables easy integration of additional features or modifications as needed.

DIY Projects

The popularity of 4040 aluminum extrusions extends to the DIY community. Hobbyists and makers appreciate the ease of use and flexibility these profiles offer. From building custom furniture to creating unique art installations, the possibilities are endless.

For example, a DIY enthusiast might use 4040 aluminum extrusions to construct a custom shelving unit. The T-slot design allows for adjustable shelves, making it easy to modify the unit as storage needs change. This adaptability is a significant draw for those looking to create personalized solutions for their homes or workshops.

Furniture and Displays

In the realm of furniture design, 4040 aluminum extrusions are increasingly being used to create modern, sleek pieces. The clean lines and minimalist aesthetic of aluminum profiles make them an attractive choice for contemporary furniture. Designers can leverage the strength and lightweight nature of these extrusions to create functional yet stylish pieces.

Moreover, 4040 aluminum extrusions are commonly used in exhibition displays and trade show booths. Their modular design allows for quick assembly and disassembly, making them ideal for events where portability is essential. The ability to customize the layout and design of the display ensures that businesses can effectively showcase their products and services.

How to Select the Right 4040 Aluminum Profile

Understanding Your Project Requirements

When selecting the right 4040 aluminum profile for your project, it is essential to understand your specific requirements. Consider factors such as load capacity, environmental conditions, and design specifications.

For instance, if you are building a frame that will support heavy machinery, you may need to choose a profile with a higher load-bearing capacity. Conversely, for lighter applications, a standard 4040 aluminum extrusion may suffice.

Sourcing Quality Extrusions

Finding reliable suppliers and manufacturers is crucial when sourcing 4040 aluminum extrusions. Look for companies that specialize in aluminum profiles and have a proven track record of quality. Reading customer reviews and seeking recommendations can help you identify reputable sources.

Additionally, consider the availability of customization options. Many suppliers offer the ability to cut and machine profiles to your specifications, ensuring that you receive the exact dimensions and features you need for your project.

Conclusion

In conclusion, 4040 aluminum extrusions offer a multitude of benefits that make them an excellent choice for various projects. Their versatility, strength, lightweight nature, and wide range of applications make them a go-to option for engineers, designers, and DIY enthusiasts alike. Whether you are constructing an industrial framework, embarking on a DIY project, or designing modern furniture, 4040 aluminum extrusions can provide the solutions you need.

As you explore the potential of 4040 aluminum extrusions in your projects, consider the specific requirements and applications that best suit your needs. With the right approach and quality materials, you can leverage the advantages of these profiles to create innovative and functional designs.

Related Questions

1. What are the main advantages of using aluminum extrusions over other materials?

Aluminum extrusions offer a superior strength-to-weight ratio, corrosion resistance, and versatility compared to materials like steel or plastic. They are also easier to work with and can be customized to meet specific project needs.

2. Can 4040 aluminum extrusions be used outdoors?

Yes, 4040 aluminum extrusions are resistant to corrosion, making them suitable for outdoor applications. However, it is essential to consider the environmental conditions and potential exposure to harsh elements.

3. How do I cut 4040 aluminum extrusions?

4040 aluminum extrusions can be cut using various tools, including miter saws, band saws, or hacksaws. It is important to use the appropriate blade designed for cutting aluminum to ensure clean cuts.

4. Are 4040 aluminum extrusions recyclable?

Yes, aluminum is highly recyclable, and 4040 aluminum extrusions can be recycled without losing their properties. This makes them an environmentally friendly choice for construction and manufacturing.

5. What types of fasteners are compatible with 4040 aluminum extrusions?

T-slot nuts and bolts are commonly used with 4040 aluminum extrusions. These fasteners allow for easy assembly and disassembly, making them ideal for modular designs.