Content Menu

● Introduction

● Benefits of Using 20x20 Aluminum Profiles

>> Structural Integrity

>> Lightweight Nature

>> Design Flexibility

>> Cost-Effectiveness

>> Ease of Assembly

>> Environmental Sustainability

● Conclusion

● Related Questions

>> 1. What are the common applications for 20x20 aluminum profiles?

>> 2. How do I cut 20x20 aluminum profiles?

>> 3. Can I paint or anodize 20x20 aluminum profiles?

>> 4. Are 20x20 aluminum profiles compatible with other materials?

>> 5. What tools do I need to assemble 20x20 aluminum profiles?

Introduction

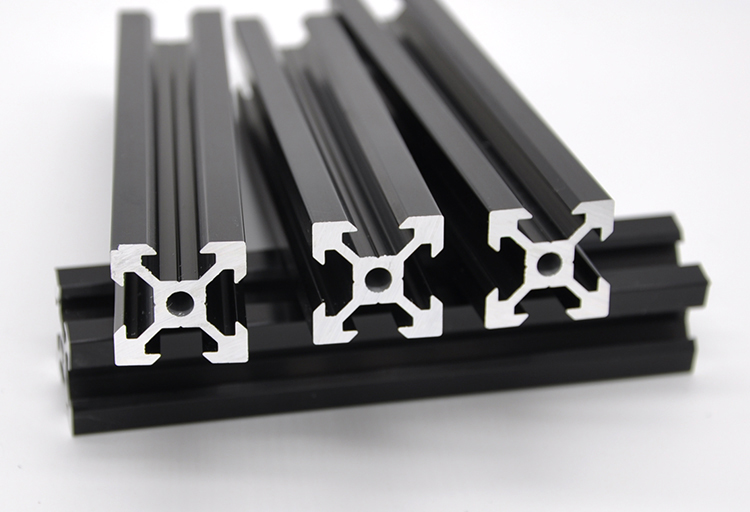

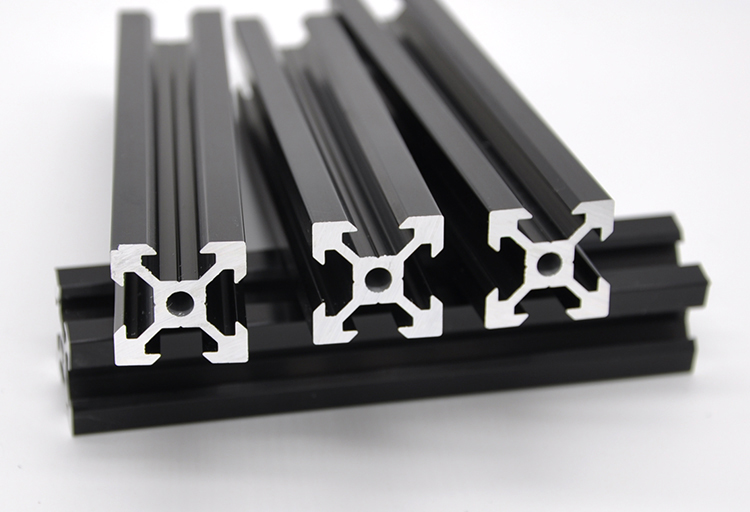

Aluminum extrusion has become a cornerstone in modern manufacturing and construction, offering a versatile solution for a wide range of applications. Among the various sizes available, the 20x20 aluminum profile stands out due to its unique combination of strength, lightweight nature, and adaptability. This article explores the key benefits of using 20x20 aluminum profiles in your projects, highlighting their structural integrity, design flexibility, and cost-effectiveness.

Benefits of Using 20x20 Aluminum Profiles

Structural Integrity

One of the primary advantages of 20x20 aluminum profiles is their exceptional structural integrity. Aluminum is known for its strength-to-weight ratio, making it an ideal material for various applications. The 20x20 profile provides a robust framework that can support significant loads while remaining lightweight. This characteristic is particularly beneficial in industries such as construction, automotive, and aerospace, where structural reliability is paramount.

The design of the 20x20 aluminum extrusion allows for easy integration into various structures, providing stability and support. Whether used in building frames, machinery, or custom fixtures, these profiles ensure that projects maintain their integrity over time. The ability to withstand environmental factors such as corrosion and temperature fluctuations further enhances their durability, making them a long-lasting choice for any project.

Lightweight Nature

The lightweight nature of 20x20 aluminum profiles is another significant benefit. Unlike steel or other heavy materials, aluminum is easy to handle and transport, reducing labor costs and improving efficiency during the construction process. This lightweight characteristic allows for quicker assembly and disassembly, making it an excellent choice for temporary structures or projects that require frequent modifications.

In addition, the reduced weight of aluminum profiles contributes to lower shipping costs and easier installation. This advantage is particularly relevant in industries where time and budget constraints are critical. By utilizing 20x20 aluminum profiles, project managers can streamline their operations and enhance overall productivity.

Design Flexibility

One of the standout features of 20x20 aluminum profiles is their design flexibility. The T-slot design allows for easy customization and modification, enabling users to create unique structures tailored to their specific needs. This adaptability is particularly beneficial for DIY enthusiasts and professionals alike, as it opens up a world of possibilities for creative projects.

The modular nature of 20x20 aluminum profiles means that they can be easily assembled and reconfigured. This feature is ideal for applications such as workstations, display stands, and machinery frames, where adjustments may be necessary over time. The ability to add or remove components without compromising the overall structure makes these profiles a practical choice for evolving project requirements.

Cost-Effectiveness

When considering materials for construction or manufacturing, cost is always a significant factor. 20x20 aluminum profiles offer a cost-effective solution without sacrificing quality. The initial investment in aluminum extrusion may be higher than some alternatives, but the long-term savings are substantial.

The durability and low maintenance requirements of aluminum profiles mean that they do not need frequent replacements or repairs. This longevity translates to lower lifecycle costs, making them a wise investment for businesses and individuals alike. Additionally, the lightweight nature of aluminum reduces shipping and handling costs, further enhancing its cost-effectiveness.

Ease of Assembly

Another key benefit of using 20x20 aluminum profiles is the ease of assembly. The T-slot design allows for quick and straightforward connections, eliminating the need for complex tools or extensive labor. This user-friendly assembly process is particularly advantageous for those who may not have extensive construction experience.

The ability to easily connect and disconnect components means that projects can be modified or expanded as needed. This flexibility is essential in dynamic environments where requirements may change frequently. Whether building a simple frame or a complex structure, the ease of assembly associated with 20x20 aluminum profiles simplifies the entire process.

Environmental Sustainability

In today's world, environmental sustainability is a crucial consideration for any project. Aluminum is a highly recyclable material, and using 20x20 aluminum profiles contributes to a more sustainable approach to construction and manufacturing. The recycling process for aluminum requires significantly less energy compared to producing new aluminum from raw materials.

By choosing aluminum profiles, you are not only benefiting from their physical properties but also making a positive impact on the environment. This commitment to sustainability can enhance your project's reputation and appeal to environmentally conscious consumers.

Conclusion

In conclusion, the benefits of using 20x20 aluminum profiles in your projects are numerous and significant. From their structural integrity and lightweight nature to their design flexibility and cost-effectiveness, these profiles offer a versatile solution for a wide range of applications. The ease of assembly and environmental sustainability further enhance their appeal, making them an excellent choice for both professionals and DIY enthusiasts.

As you consider materials for your next project, keep in mind the advantages that 20x20 aluminum profiles can provide. Their unique properties and adaptability make them a valuable asset in any construction or manufacturing endeavor.

Related Questions

1. What are the common applications for 20x20 aluminum profiles?

20x20 aluminum profiles are commonly used in various applications, including industrial machinery frames, workstations, display stands, and custom enclosures. Their versatility allows them to be adapted for numerous projects.

2. How do I cut 20x20 aluminum profiles?

Cutting 20x20 aluminum profiles can be done using a miter saw or a band saw with a fine-toothed blade. It's essential to secure the profile properly and wear safety gear during the cutting process.

3. Can I paint or anodize 20x20 aluminum profiles?

Yes, 20x20 aluminum profiles can be painted or anodized to enhance their appearance and provide additional protection against corrosion. Anodizing also allows for a variety of color options.

4. Are 20x20 aluminum profiles compatible with other materials?

Yes, 20x20 aluminum profiles can be easily integrated with other materials such as wood, plastic, and steel. This compatibility allows for creative and functional designs in various projects.

5. What tools do I need to assemble 20x20 aluminum profiles?

To assemble 20x20 aluminum profiles, you will typically need basic tools such as an Allen wrench, a screwdriver, and a measuring tape. Additional tools may be required depending on the complexity of the project.