Content Menu

● Versatility in Design

● Strength and Durability

● Ease of Assembly

● Cost-Effectiveness

● Compatibility with CAD Software

● Customization Options

● Lightweight Nature

● Eco-Friendly Material

● Aesthetic Appeal

● Applications Across Industries

● Conclusion

● Frequently Asked Questions

>> 1. What is the maximum length for a 20x20 aluminum extrusion?

>> 2. Can 20x20 aluminum extrusions be used outdoors?

>> 3. How do I cut 20x20 aluminum extrusions?

>> 4. Are there specific connectors for 20x20 aluminum extrusions?

>> 5. What finishes are available for 20x20 aluminum extrusions?

Aluminum extrusions have become a cornerstone in modern engineering and design, particularly in the realm of Computer-Aided Design (CAD). Among the various sizes and profiles available, the 20x20 aluminum extrusion stands out due to its versatility, strength, and ease of use. This article explores the key benefits of using 20x20 aluminum extrusions in CAD projects, highlighting their applications, advantages, and the reasons why they are favored by engineers and designers alike.

Versatility in Design

One of the most significant advantages of 20x20 aluminum extrusions is their versatility. These extrusions can be used in a wide range of applications, from structural frames to custom enclosures. The square profile allows for easy integration into various designs, making it suitable for both industrial and consumer products. Designers can create complex structures without the need for extensive modifications, as the extrusion can be cut and assembled in numerous configurations.

The adaptability of the 20x20 profile means it can be used in everything from robotics to furniture design. For instance, in robotics, the extrusions can form the frame of a robot, providing a lightweight yet sturdy structure that can support various components. In furniture design, the clean lines of the aluminum can create modern, minimalist pieces that are both functional and aesthetically pleasing.

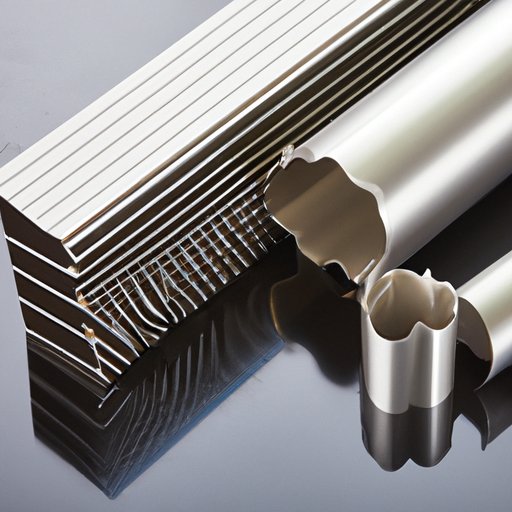

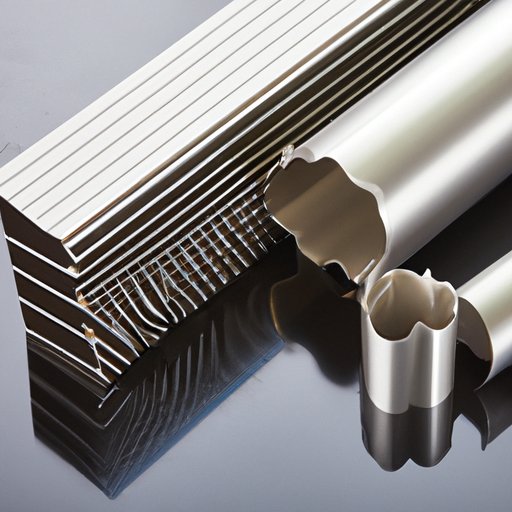

Strength and Durability

Aluminum is known for its excellent strength-to-weight ratio, and the 20x20 extrusion is no exception. This profile provides substantial structural integrity while remaining lightweight, making it ideal for applications where weight is a critical factor. The durability of aluminum also means that structures made from these extrusions can withstand harsh environmental conditions, including moisture, corrosion, and temperature fluctuations.

In industries such as aerospace and automotive, where performance and safety are paramount, the strength of 20x20 aluminum extrusions ensures that components can endure significant stress without failure. This reliability is crucial for maintaining the integrity of complex systems and ensuring the safety of end-users.

Ease of Assembly

Another key benefit of using 20x20 aluminum extrusions in CAD projects is the ease of assembly. The T-slot design allows for quick and straightforward connections between different components. This feature significantly reduces assembly time and labor costs, making it an attractive option for both small-scale and large-scale projects. Additionally, the ability to disassemble and reconfigure structures easily means that designs can be modified or expanded as needed.

The straightforward assembly process is particularly beneficial in prototyping and iterative design. Engineers can quickly build and test their designs, making adjustments as necessary without the need for specialized tools or extensive labor. This flexibility accelerates the development cycle, allowing for faster innovation and time-to-market.

Cost-Effectiveness

When considering materials for CAD projects, cost is always a factor. 20x20 aluminum extrusions offer a cost-effective solution without compromising quality. The manufacturing process for aluminum extrusions is efficient, which helps keep production costs low. Furthermore, the longevity and durability of aluminum mean that projects require less maintenance over time, leading to further savings.

In addition to direct cost savings, the use of aluminum extrusions can also lead to reduced waste during the manufacturing process. The ability to create custom lengths and profiles minimizes excess material, contributing to a more sustainable production approach.

Compatibility with CAD Software

The integration of 20x20 aluminum extrusions into CAD software is seamless. Most CAD programs have libraries of standard profiles, including the 20x20 extrusion, allowing designers to easily incorporate these components into their projects. This compatibility streamlines the design process, enabling engineers to visualize their projects accurately and make necessary adjustments before production.

Moreover, the ability to simulate the performance of aluminum extrusions within CAD software allows for better decision-making during the design phase. Engineers can analyze stress points, weight distribution, and overall structural integrity, ensuring that the final product meets all necessary specifications and standards.

Customization Options

Aluminum extrusions can be customized to meet specific project requirements. The 20x20 profile can be modified in terms of length, surface finish, and additional features such as holes or grooves. This level of customization allows designers to create unique solutions tailored to their needs, enhancing the functionality and aesthetics of their projects.

For example, custom machining can be applied to create specific mounting points or to integrate other components seamlessly. This flexibility is particularly valuable in specialized applications, such as medical devices or custom machinery, where standard solutions may not suffice.

Lightweight Nature

The lightweight nature of aluminum extrusions is particularly beneficial in applications where weight reduction is crucial. For instance, in the aerospace and automotive industries, every gram counts. The 20x20 aluminum extrusion provides a robust solution without adding unnecessary weight, making it an ideal choice for these sectors.

This lightweight characteristic also contributes to energy efficiency. In transportation applications, reducing weight can lead to lower fuel consumption and emissions, aligning with global sustainability goals. As industries increasingly focus on reducing their environmental impact, the use of lightweight materials like aluminum becomes even more critical.

Eco-Friendly Material

Aluminum is a highly recyclable material, making it an environmentally friendly choice for construction and manufacturing. Using 20x20 aluminum extrusions in CAD projects not only supports sustainable practices but also reduces the carbon footprint associated with production. This aspect is increasingly important as industries strive to adopt greener practices.

The recycling process for aluminum is efficient and requires only a fraction of the energy needed to produce new aluminum from ore. This energy savings translates into lower greenhouse gas emissions, making aluminum a preferred material for environmentally conscious companies.

Aesthetic Appeal

The clean lines and modern appearance of aluminum extrusions contribute to their aesthetic appeal. The 20x20 profile can be finished in various ways, including anodizing or powder coating, to enhance its visual characteristics. This versatility allows designers to create visually appealing products that meet both functional and aesthetic requirements.

In architectural applications, aluminum extrusions can be used to create striking facades or interior elements that combine beauty with functionality. The ability to customize finishes means that designers can match the aluminum to other materials or color schemes, ensuring a cohesive look throughout a project.

Applications Across Industries

The applications of 20x20 aluminum extrusions span numerous industries, including:

- Manufacturing: Used for machine frames, workstations, and conveyor systems.

- Automotive: Employed in vehicle structures and components.

- Aerospace: Utilized in lightweight structural components.

- Electronics: Used for enclosures and mounting systems.

- Furniture: Incorporated into modern furniture designs for both functionality and style.

In each of these sectors, the unique properties of 20x20 aluminum extrusions provide solutions that enhance performance, reduce costs, and improve overall design quality.

Conclusion

In summary, the 20x20 aluminum extrusion offers a multitude of benefits for CAD projects, including versatility, strength, ease of assembly, cost-effectiveness, and compatibility with design software. Its lightweight nature, customization options, and eco-friendly characteristics further enhance its appeal across various industries. As designers and engineers continue to seek innovative solutions, the 20x20 aluminum extrusion will undoubtedly remain a popular choice in the world of CAD.

Frequently Asked Questions

1. What is the maximum length for a 20x20 aluminum extrusion?

The maximum length can vary by manufacturer, but standard lengths are typically available in 1-meter, 2-meter, and 3-meter options.

2. Can 20x20 aluminum extrusions be used outdoors?

Yes, aluminum is resistant to corrosion, making it suitable for outdoor applications. However, a protective finish is recommended for prolonged exposure to harsh environments.

3. How do I cut 20x20 aluminum extrusions?

You can cut aluminum extrusions using a miter saw with a fine-toothed blade or a band saw. Ensure to measure accurately before cutting.

4. Are there specific connectors for 20x20 aluminum extrusions?

Yes, there are various connectors and brackets designed specifically for T-slot aluminum extrusions, allowing for secure and flexible assembly.

5. What finishes are available for 20x20 aluminum extrusions?

Common finishes include anodizing, powder coating, and mill finish, each offering different aesthetic and protective properties.