Content Menu

● Understanding Aluminum Extrusion

● Key Benefits of 20 Series Aluminum Extrusion

>> Versatility in Design

>> Lightweight Yet Strong

>> Corrosion Resistance

>> Ease of Fabrication and Assembly

>> Sustainability

>> Cost-Effectiveness

>> Aesthetic Appeal

>> Thermal Conductivity

>> Compatibility with Automation

>> Wide Range of Applications

● Conclusion

● Frequently Asked Questions

>> 1. What industries commonly use 20 series aluminum extrusion?

>> 2. Can 20 series aluminum extrusions be customized?

>> 3. How does aluminum extrusion compare to other materials?

>> 4. What finishing options are available for aluminum extrusions?

>> 5. Is aluminum extrusion environmentally friendly?

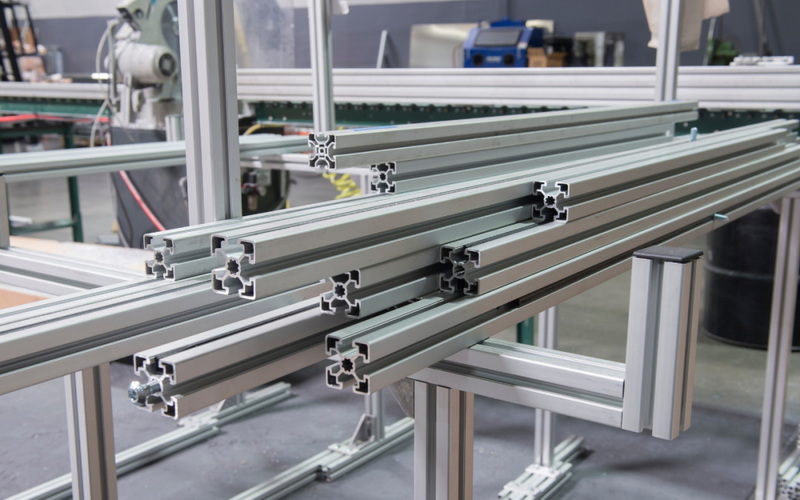

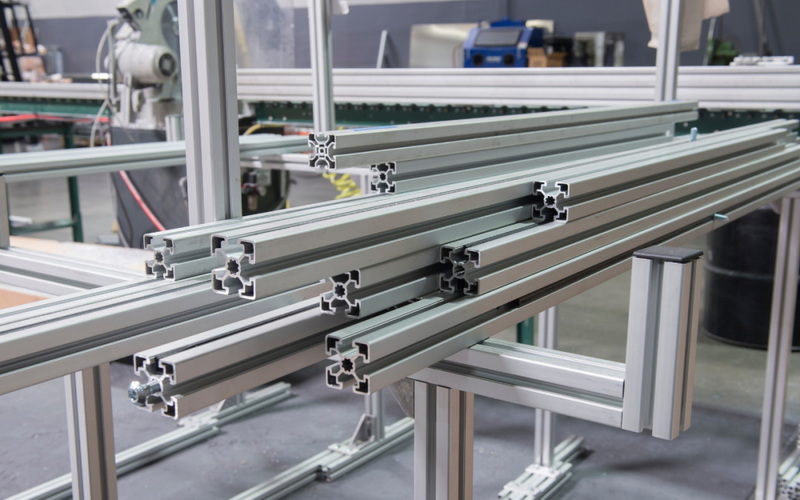

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. Among the various series of aluminum extrusions, the 20 series is particularly popular in industrial applications due to its unique properties and versatility. This article explores the key benefits of using 20 series aluminum extrusion in industrial settings, highlighting its applications, advantages, and the reasons behind its widespread use.

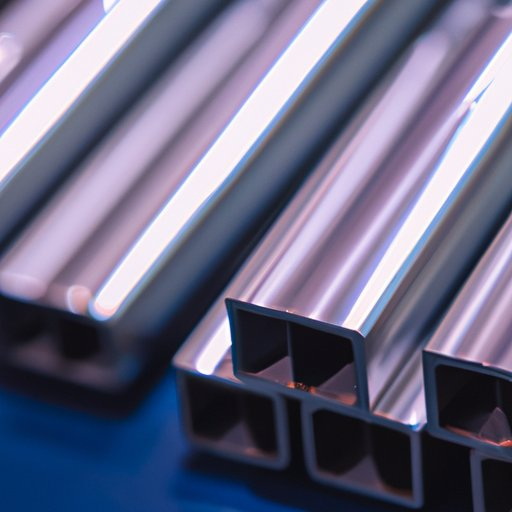

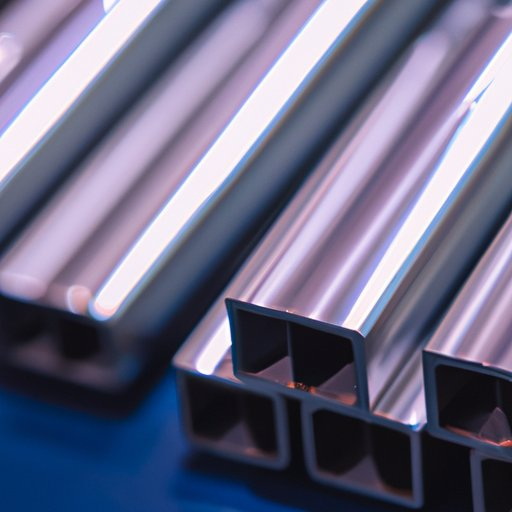

The process of aluminum extrusion involves forcing aluminum alloy through a die to create a specific shape. This method allows for the production of complex profiles that can be tailored to meet specific requirements. The resulting extrusions are lightweight, strong, and resistant to corrosion, making them ideal for various applications.

Key Benefits of 20 Series Aluminum Extrusion

Versatility in Design

One of the most significant advantages of 20 series aluminum extrusion is its versatility. The 20 series profiles can be designed to meet a wide range of specifications, making them suitable for various applications. Whether it's for structural components, frames, or enclosures, the adaptability of 20 series extrusions allows engineers and designers to create custom solutions that fit their needs.

The ability to create intricate designs without compromising strength is a game-changer in industries where precision and customization are paramount. For instance, in the automotive industry, 20 series aluminum extrusions can be used to manufacture lightweight frames that enhance fuel efficiency while maintaining structural integrity.

Lightweight Yet Strong

Aluminum is known for its lightweight properties, and the 20 series is no exception. The strength-to-weight ratio of aluminum extrusions is one of the highest among construction materials. This characteristic is particularly beneficial in industries where reducing weight is crucial, such as aerospace and automotive. The lightweight nature of 20 series aluminum extrusions allows for easier handling and installation, reducing labor costs and improving efficiency.

In aerospace applications, for example, every ounce counts. Using 20 series aluminum extrusions can significantly reduce the overall weight of aircraft, leading to lower fuel consumption and increased payload capacity. This advantage is not only economically beneficial but also contributes to environmental sustainability by reducing carbon emissions.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, which helps prevent corrosion. This property is especially important in industrial applications where components may be exposed to harsh environments. The 20 series aluminum extrusion is highly resistant to corrosion, making it suitable for outdoor applications and environments with high humidity or exposure to chemicals.

For instance, in marine applications, where components are constantly exposed to saltwater, the corrosion resistance of aluminum extrusions ensures longevity and reliability. This durability reduces the need for frequent replacements, ultimately saving costs and resources.

Ease of Fabrication and Assembly

The 20 series aluminum extrusions can be easily cut, drilled, and machined, allowing for quick fabrication and assembly. This ease of use translates to shorter lead times and reduced production costs. Additionally, the availability of various connectors and fasteners designed specifically for aluminum extrusions simplifies the assembly process, making it more efficient.

In manufacturing environments where time is of the essence, the ability to quickly assemble components can lead to significant productivity gains. For example, in the construction of modular buildings, 20 series aluminum extrusions can be rapidly assembled on-site, reducing construction time and labor costs.

Sustainability

Aluminum is a highly recyclable material, and using 20 series aluminum extrusions contributes to sustainability efforts in manufacturing. The recycling process for aluminum requires only a fraction of the energy needed to produce new aluminum from ore. This characteristic makes aluminum extrusions an environmentally friendly choice for manufacturers looking to reduce their carbon footprint.

Moreover, the long lifespan of aluminum products means that they do not need to be replaced frequently, further contributing to sustainability. By choosing 20 series aluminum extrusions, companies can align their operations with green initiatives and appeal to environmentally conscious consumers.

Cost-Effectiveness

While the initial cost of aluminum extrusions may be higher than some other materials, the long-term benefits often outweigh the initial investment. The durability, low maintenance requirements, and energy efficiency of aluminum extrusions can lead to significant cost savings over time. Additionally, the lightweight nature of aluminum can reduce shipping costs and improve overall project economics.

In many cases, the total cost of ownership for aluminum extrusions is lower than that of other materials, making them a smart investment for businesses. For example, in the automotive industry, the use of lightweight aluminum components can lead to lower fuel costs over the vehicle's lifespan, offsetting the initial material costs.

Aesthetic Appeal

Aluminum extrusions can be finished in various ways, including anodizing, painting, and powder coating. This versatility in finishing options allows manufacturers to create visually appealing products that meet aesthetic requirements. The sleek appearance of 20 series aluminum extrusions makes them suitable for applications where design and aesthetics are essential, such as in consumer products and architectural elements.

In architectural applications, for instance, aluminum extrusions can be used to create modern facades that enhance the visual appeal of buildings while providing structural support. The ability to customize finishes also allows for branding opportunities, as companies can match their products to their corporate colors.

Thermal Conductivity

Aluminum has excellent thermal conductivity, making it an ideal choice for applications that require heat dissipation. The 20 series aluminum extrusions can be used in heat sinks and other thermal management solutions, ensuring efficient heat transfer and maintaining optimal operating temperatures for various devices.

In electronics, for example, aluminum extrusions are often used in heat sinks to dissipate heat generated by components, preventing overheating and ensuring reliable performance. This application is critical in maintaining the longevity and efficiency of electronic devices.

Compatibility with Automation

In modern manufacturing environments, automation plays a crucial role in improving efficiency and productivity. The 20 series aluminum extrusions are compatible with various automation systems, allowing for seamless integration into automated production lines. This compatibility enhances the overall efficiency of manufacturing processes and reduces the need for manual labor.

As industries continue to adopt automation technologies, the demand for components that can easily integrate into these systems will grow. The 20 series aluminum extrusions provide a reliable solution for manufacturers looking to enhance their production capabilities.

Wide Range of Applications

The versatility and benefits of 20 series aluminum extrusions make them suitable for a wide range of applications across various industries. From automotive and aerospace to construction and consumer products, the 20 series can be found in numerous applications, demonstrating its adaptability and effectiveness.

In the construction industry, for example, 20 series aluminum extrusions are often used in the fabrication of window frames, curtain walls, and structural supports. Their lightweight nature and strength make them ideal for these applications, providing both functionality and aesthetic appeal.

Conclusion

In conclusion, the 20 series aluminum extrusion offers numerous benefits that make it an ideal choice for industrial applications. Its versatility in design, lightweight yet strong properties, corrosion resistance, ease of fabrication, sustainability, cost-effectiveness, aesthetic appeal, thermal conductivity, compatibility with automation, and wide range of applications all contribute to its popularity in various industries. As manufacturers continue to seek innovative solutions, the 20 series aluminum extrusion will undoubtedly remain a key player in the world of industrial applications.

Frequently Asked Questions

1. What industries commonly use 20 series aluminum extrusion?

The 20 series aluminum extrusion is commonly used in industries such as automotive, aerospace, construction, and consumer products due to its versatility and strength.

2. Can 20 series aluminum extrusions be customized?

Yes, 20 series aluminum extrusions can be customized to meet specific design requirements, allowing for tailored solutions in various applications.

3. How does aluminum extrusion compare to other materials?

Aluminum extrusion offers a superior strength-to-weight ratio, corrosion resistance, and ease of fabrication compared to many other materials, making it a preferred choice in many applications.

4. What finishing options are available for aluminum extrusions?

Aluminum extrusions can be finished through anodizing, painting, and powder coating, providing aesthetic appeal and additional protection against corrosion.

5. Is aluminum extrusion environmentally friendly?

Yes, aluminum is highly recyclable, and using aluminum extrusions contributes to sustainability efforts in manufacturing by reducing energy consumption and waste.