Content Menu

● Introduction to Eurotech Extrusion Machinery

>> Key Features of Eurotech Extrusion Machinery

● Technological Advancements

● Customer-Centric Approach

>> Customer Testimonials

● Contributions to Sustainability

>> Bio-Based Materials Processing

>> Recycled Materials Integration

● Future Developments and Trends

>> 3D Printing and Extrusion

● Eurotech's Role in the Circular Economy

>> Energy Efficiency and Waste Reduction

● Conclusion

● Frequently Asked Questions

>> 1. What types of extrusion machinery does Eurotech offer?

>> 2. How does Eurotech contribute to sustainability in the plastics industry?

>> 3. What technological advancements does Eurotech integrate into their machinery?

>> 4. What kind of customer support does Eurotech provide?

>> 5. Can Eurotech machinery handle a variety of thermoplastic materials?

● Citations:

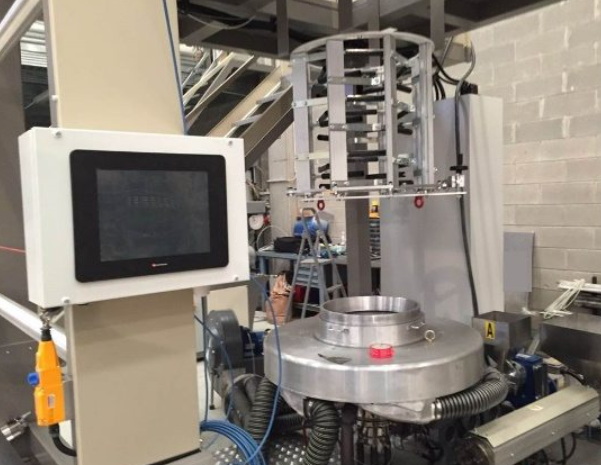

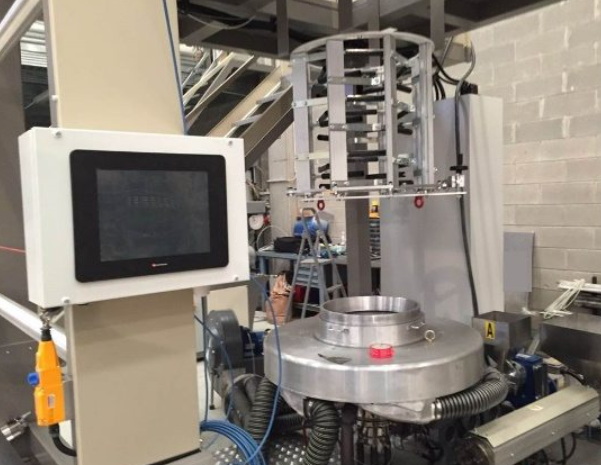

Eurotech Extrusion Machinery has been a leading provider of innovative extrusion solutions since 1999, catering to the needs of laboratories, R&D departments, and industrial production lines. Their expertise lies in designing and manufacturing customized extrusion lines for processing thermoplastic materials, including bio-based and recycled materials. This article will delve into the key benefits of Eurotech Extrusion Machinery, highlighting their technological advancements, customer-centric approach, and contributions to sustainable practices.

Introduction to Eurotech Extrusion Machinery

Eurotech Extrusion Machinery Srl specializes in providing complete extrusion solutions and systems for various sectors of plastic extrusion technologies. Their focus on innovation and customer satisfaction has made them a reliable partner for companies involved in the production and processing of thermoplastic materials. With over 30 years of experience in the field, their technicians bring extensive knowledge to the design and engineering of extrusion machinery.

Key Features of Eurotech Extrusion Machinery

1. Customized Solutions: Eurotech offers tailored solutions to meet specific customer needs, ensuring that each machine is designed to optimize production processes for different types of thermoplastic materials.

2. State-of-the-Art Technology: They incorporate the latest technologies to enhance efficiency, precision, and sustainability in extrusion processes. This includes advanced control systems and materials handling capabilities.

3. Focus on Sustainability: Eurotech emphasizes the use of recycled and bio-based materials, contributing to a more environmentally friendly production process.

Technological Advancements

Eurotech Extrusion Machinery integrates cutting-edge technologies into their systems to improve performance and efficiency. Some notable technological advancements include:

- Advanced Control Systems: Eurotech uses programmable logic controllers (PLCs) which provide precise temperature control, intuitive interfaces, and responsive alarm systems. These features enhance operational efficiency and reduce downtime.

- Data Acquisition and Analysis: Their machines often come equipped with data acquisition capabilities, allowing for real-time monitoring of pressure and temperature curves. This data is crucial for optimizing extrusion processes and ensuring consistent product quality.

- Automation and AI: The future of extrusion technology involves integrating automation and artificial intelligence (AI) to achieve more precise control over processes. AI algorithms can recognize patterns in production data, helping to optimize processes, reduce material waste, and increase efficiency[2].

Customer-Centric Approach

Eurotech prioritizes customer satisfaction by offering customized solutions that meet specific needs. Their machines are designed to be versatile, accommodating a wide range of polymers and applications, from blown film to sheet extrusion.

Customer Testimonials

Eurotech's commitment to innovation and customer service has earned them a strong reputation among clients. For instance, their collaboration with various partners has been praised for providing quick feedback and updates based on customer requests.

Contributions to Sustainability

Eurotech Extrusion Machinery plays a significant role in promoting sustainable practices within the plastics industry. They focus on processing recycled and bio-based materials, which reduces reliance on virgin plastics and supports a more circular economy.

Bio-Based Materials Processing

Eurotech has successfully processed multilayer transparent bio-based barrier films in collaboration with other industry leaders. These films offer excellent gas and aroma barriers while being compostable, reducing environmental impact.

Recycled Materials Integration

By integrating recycled materials into their production lines, Eurotech helps reduce the demand for virgin plastics. This approach not only diminishes environmental impact but also supports the circular economy by encouraging the reuse and recycling of plastic products[3].

Future Developments and Trends

The future of extrusion technology looks promising, with advancements in new materials and technologies. Bioplastics, high-performance polymers, and the integration of 3D printing with extrusion processes are opening up new possibilities for more efficient and environmentally friendly manufacturing[2].

3D Printing and Extrusion

The combination of 3D printing technologies with traditional extrusion processes allows for the creation of complex geometries that were previously difficult or impossible to extrude. This integration opens up new possibilities in manufacturing, enabling the production of customized products with unique properties[2].

Eurotech's Role in the Circular Economy

Eurotech Extrusion Machinery is committed to enhancing circular economy processes through sustainable plastic processing. They develop equipment that supports the research and improvement of recycled and bio-based material usage, aligning with the "ZERO WASTE MISSION" of the Syncro Group[5].

Energy Efficiency and Waste Reduction

In addition to using recycled materials, Eurotech aims to minimize energy consumption and waste generation during the extrusion process. This approach not only reduces environmental impact but also leads to cost savings, demonstrating that environmental responsibility can go hand in hand with economic benefits[3].

Conclusion

Eurotech Extrusion Machinery offers a comprehensive range of benefits, from technological innovation to sustainability and customer satisfaction. Their commitment to providing customized solutions and embracing advanced technologies positions them as a leader in the extrusion machinery sector.

Frequently Asked Questions

1. What types of extrusion machinery does Eurotech offer?

Eurotech Extrusion Machinery offers a variety of extrusion solutions, including single-screw and twin-screw extruders, as well as complete lines for blown film, cast film, sheet, and profile extrusion. Their machinery is designed for both laboratory and industrial-scale production.

2. How does Eurotech contribute to sustainability in the plastics industry?

Eurotech contributes to sustainability by focusing on the processing of recycled and bio-based materials. This approach helps reduce the industry's reliance on virgin plastics and supports a more circular economy.

3. What technological advancements does Eurotech integrate into their machinery?

Eurotech integrates advanced control systems, data acquisition capabilities, and automation technologies into their machinery. These features enhance operational efficiency and optimize extrusion processes.

4. What kind of customer support does Eurotech provide?

Eurotech is known for its customer-centric approach, offering customized solutions tailored to meet specific client needs. They prioritize customer satisfaction and provide ongoing support to ensure optimal machine performance.

5. Can Eurotech machinery handle a variety of thermoplastic materials?

Yes, Eurotech Extrusion Machinery is designed to handle a wide range of thermoplastic materials, including recycled and bio-based polymers. Their machines are versatile and can be configured to process different materials efficiently.

Citations:

[1] https://www.eurexma.com/en

[2] https://kama-packaging.com/en/the-future-of-extrusion-technology-new-materials-and-technologies/

[3] http://www.adeptcorp.com/sustainable-plastic-extrusion-practices/

[4] https://www.eurexma.com/en/pages/716-company

[5] https://it.linkedin.com/company/eurexma

[6] https://www.eurotech.com/wp-content/uploads/2023/12/2022_Eurotech_Sustainability_Pathway-1.pdf

[7] https://test.gojakagenzia.com/wp-content/uploads/2020/10/Eurotech_Product_Portfolio_2020.pdf

[8] https://machinesitalia.org/company/eurotech-extrusion-machinery-srl

[9] https://www.eurotech.com/wp-content/uploads/2024/12/2023_ETH_Global_Compact.pdf

[10] https://www.sukano.com/en/company/news/goodbye-petroleum-hello-bio

[11] https://marktech.com.tw/download/Marketing_Content/28_Success-story_Eurotech_763298.pdf

[12] https://www.eurotech-group.co.uk/news/exciting-developments-at-the-eurotech-group/

[13] https://eurotechmachinery.com/why-eurotech/

[14] https://www.eurotech.com/industries/

[15] https://www.eurotec-ep.com/en/

[16] https://eurotechmachinery.com

[17] https://it.linkedin.com/in/luca-lepori-b6b259b4

[18] https://ditchcarbon.com/organizations/eurotech

[19] https://www.eurotec.team/en/about-us/production

[20] https://it.linkedin.com/in/paolo-azzoni-a443614a