Content Menu

● Introduction

● Understanding Custom Aluminum Profiles

● Benefits of Custom Aluminum Profiles

>> Design Flexibility

>> Cost-Effectiveness

>> Lightweight and Durable

>> Corrosion Resistance

● Applications of Custom Aluminum Profiles

● Choosing the Right Manufacturer

● Conclusion

● Related Questions

>> 1. What industries benefit the most from custom aluminum profiles?

>> 2. How does the aluminum extrusion process work?

>> 3. What are the environmental benefits of using aluminum?

>> 4. Can custom aluminum profiles be designed for specific applications?

>> 5. What factors should I consider when choosing a custom aluminum profile manufacturer?

Introduction

In the realm of modern manufacturing, the significance of materials cannot be overstated. Among these materials, aluminum stands out due to its unique properties and versatility. Custom aluminum profiles, created through the aluminum extrusion process, have become increasingly popular across various industries. This article delves into the key benefits of custom aluminum profiles, exploring their design flexibility, cost-effectiveness, lightweight durability, corrosion resistance, and diverse applications.

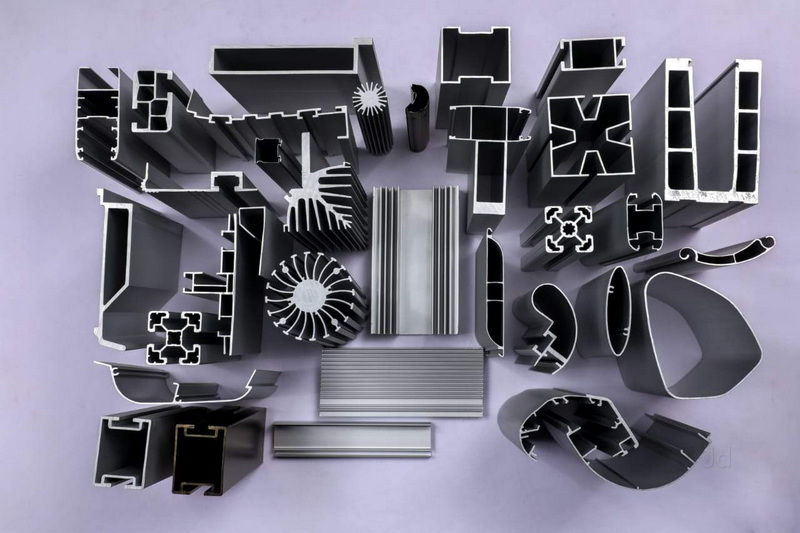

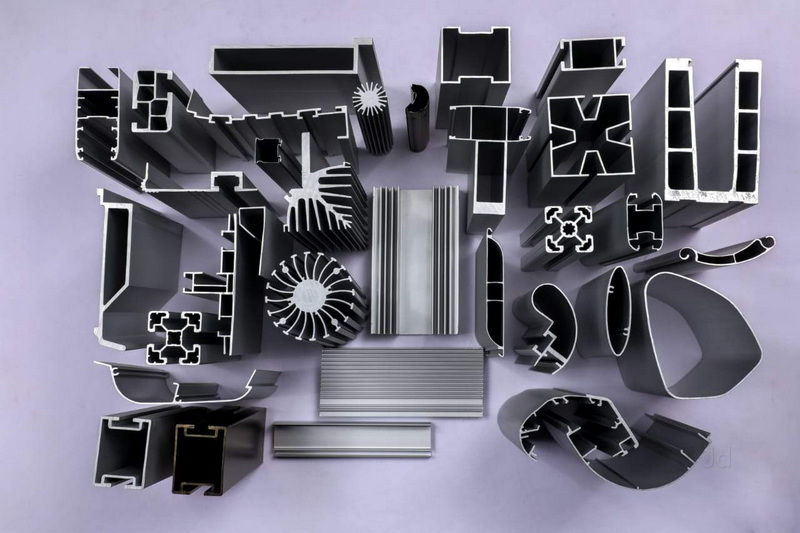

Understanding Custom Aluminum Profiles

Custom aluminum profiles are specifically designed shapes made from aluminum through a process known as extrusion. During this process, aluminum billets are heated and forced through a die, resulting in a continuous profile that can be cut to desired lengths. This method allows for the creation of complex shapes that meet specific design requirements, making custom aluminum profiles an ideal choice for a wide range of applications.

The aluminum extrusion process is not only efficient but also environmentally friendly. Aluminum is 100% recyclable, and the extrusion process generates minimal waste, making it a sustainable option for manufacturers looking to reduce their environmental footprint.

Benefits of Custom Aluminum Profiles

Design Flexibility

One of the most significant advantages of custom aluminum profiles is their design flexibility. Manufacturers can create intricate shapes and designs that are tailored to specific applications. This flexibility allows for innovation in product design, enabling engineers and designers to push the boundaries of what is possible.

For instance, in the automotive industry, custom aluminum profiles can be designed to fit unique vehicle structures, enhancing both aesthetics and functionality. Similarly, in the construction sector, architects can utilize custom profiles to create visually appealing and structurally sound buildings.

Cost-Effectiveness

Custom aluminum profiles can be a cost-effective solution for manufacturers. While the initial investment in custom tooling may be higher than standard profiles, the long-term savings can be substantial. Custom profiles often lead to reduced material waste, as they are designed to meet specific requirements without excess material.

Moreover, the efficiency of the aluminum extrusion process means that manufacturers can produce large quantities of custom profiles quickly. This speed not only reduces labor costs but also shortens lead times, allowing companies to respond swiftly to market demands.

Lightweight and Durable

Aluminum is renowned for its strength-to-weight ratio, making custom aluminum profiles an excellent choice for applications where weight is a critical factor. The lightweight nature of aluminum allows for easier handling and transportation, which is particularly beneficial in industries such as aerospace and automotive.

Despite being lightweight, custom aluminum profiles are incredibly durable. They can withstand significant stress and strain, making them suitable for structural applications. This durability ensures that products made from custom aluminum profiles have a long lifespan, reducing the need for frequent replacements.

Corrosion Resistance

Another key benefit of custom aluminum profiles is their inherent corrosion resistance. Aluminum naturally forms a protective oxide layer when exposed to air, which helps prevent rust and degradation. This property is particularly advantageous in environments where exposure to moisture and chemicals is common.

To enhance corrosion resistance further, custom aluminum profiles can undergo anodizing or other finishing processes. These treatments not only improve the material's resistance to corrosion but also enhance its aesthetic appeal, allowing for a variety of colors and finishes.

Applications of Custom Aluminum Profiles

Custom aluminum profiles find applications across numerous industries, showcasing their versatility and adaptability. Here are some notable examples:

- Aerospace: In the aerospace industry, custom aluminum profiles are used in aircraft frames, wings, and fuselage components. Their lightweight and strong properties contribute to fuel efficiency and overall performance.

- Automotive: Custom profiles are utilized in vehicle structures, including chassis and body components. The ability to design profiles that meet specific safety and performance standards is crucial in this industry.

- Construction: Architects and builders use custom aluminum profiles for window frames, curtain walls, and structural supports. The design flexibility allows for innovative architectural solutions.

- Electronics: Custom aluminum profiles are often used in the manufacturing of electronic enclosures and heat sinks. Their thermal conductivity helps dissipate heat, ensuring the longevity of electronic components.

- Furniture: In the furniture industry, custom aluminum profiles are used to create modern and stylish designs. Their lightweight nature makes them easy to handle, while their durability ensures long-lasting products.

Choosing the Right Manufacturer

Selecting the right manufacturer for custom aluminum profiles is crucial to ensuring quality and reliability. Here are some key factors to consider:

- Experience and Expertise: Look for manufacturers with a proven track record in producing custom aluminum profiles. Their experience can significantly impact the quality of the final product.

- Quality Control: Ensure that the manufacturer has stringent quality control measures in place. This includes regular inspections and testing of materials to meet industry standards.

- Customization Options: Choose a manufacturer that offers a wide range of customization options, including different shapes, sizes, and finishes. This flexibility allows you to create profiles that meet your specific needs.

- Customer Support: A manufacturer that provides excellent customer support can help you navigate the design and production process more smoothly. Look for companies that are responsive and willing to collaborate on your project.

Conclusion

Custom aluminum profiles offer numerous benefits that make them an essential component in modern manufacturing. Their design flexibility, cost-effectiveness, lightweight durability, and corrosion resistance make them suitable for a wide range of applications across various industries. As manufacturers continue to innovate and push the boundaries of design, the demand for custom aluminum profiles is likely to grow, solidifying their place in the future of manufacturing.

Related Questions

1. What industries benefit the most from custom aluminum profiles?

Custom aluminum profiles are widely used in industries such as aerospace, automotive, construction, electronics, and furniture, where their unique properties can be fully utilized.

2. How does the aluminum extrusion process work?

The aluminum extrusion process involves heating aluminum billets and forcing them through a die to create continuous profiles that can be cut to specific lengths.

3. What are the environmental benefits of using aluminum?

Aluminum is 100% recyclable, and the extrusion process generates minimal waste, making it an environmentally friendly choice for manufacturers.

4. Can custom aluminum profiles be designed for specific applications?

Yes, custom aluminum profiles can be tailored to meet specific design requirements, allowing for innovation and creativity in product development.

5. What factors should I consider when choosing a custom aluminum profile manufacturer?

Consider the manufacturer's experience, quality control measures, customization options, and customer support when selecting a manufacturer for custom aluminum profiles.