Content Menu

● 1. Introduction to PVC Pipe Extrusion

● 2. Key Components of the PVC Pipe Extrusion Line

● 3. Benefits of China PVC Pipe Extrusion Production Line

>> - High Efficiency and Productivity

>> - Cost-Effectiveness

>> - Versatility in Applications

>> - Durability and Longevity

>> - Lightweight Nature

>> - Environmental Benefits

● 4. Technological Advancements in Extrusion Lines

● 5. Conclusion

● FAQ

>> 1. What types of pipes can be produced using a China PVC pipe extrusion production line?

>> 2. How does automation improve the efficiency of the PVC pipe extrusion process?

>> 3. Are there environmental benefits associated with using PVC pipes?

>> 4. What are some key technological advancements in modern PVC pipe extrusion lines?

>> 5. Why is China a leader in PVC pipe extrusion technology?

● Citations:

The PVC pipe extrusion production line has become a cornerstone in the manufacturing of pipes used across various industries. China, being a leading manufacturer, has developed advanced technologies that enhance the efficiency and quality of PVC pipe production. This article explores the key benefits of the China PVC pipe extrusion production line, its operational mechanisms, and its significance in modern manufacturing.

1. Introduction to PVC Pipe Extrusion

PVC (Polyvinyl Chloride) is a widely used thermoplastic material known for its durability, lightweight nature, and resistance to corrosion. The process of extrusion involves forcing melted PVC through a die to create pipes of various shapes and sizes. The China PVC pipe extrusion production line integrates several components that work together to ensure efficient and high-quality production.

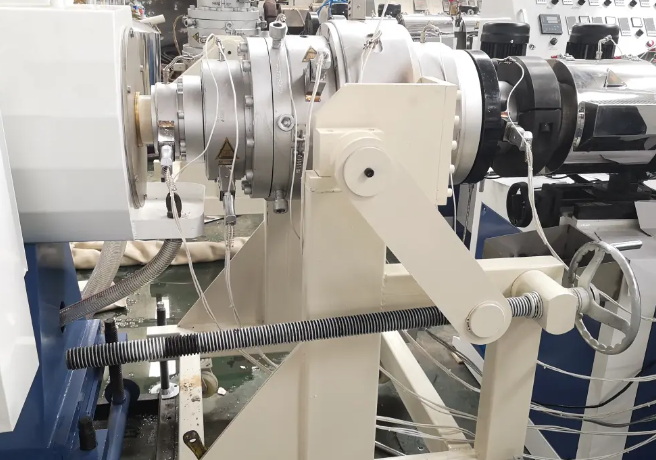

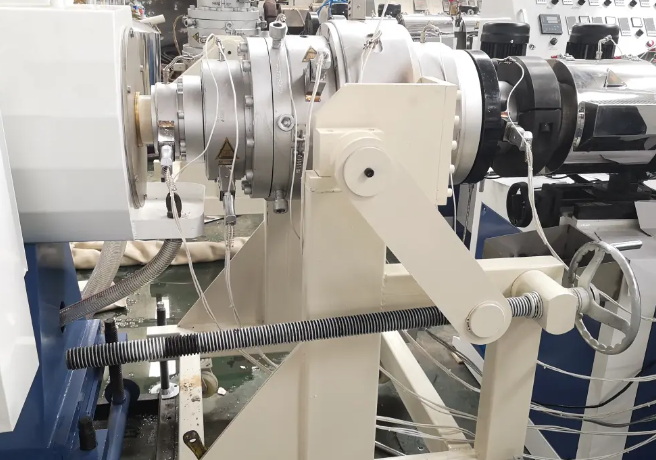

2. Key Components of the PVC Pipe Extrusion Line

Understanding the components of the PVC pipe extrusion line is essential to appreciate its benefits:

- Extruder: The heart of the production line, where raw PVC is melted and mixed.

- Die Head: Shapes the melted PVC into the desired pipe form.

- Calibration Tank: Cools and sets the shape of the extruded pipes.

- Haul-off Unit: Pulls the cooled pipes from the die head at a controlled speed.

- Cutting Machine: Cuts pipes to specified lengths.

Each component plays a crucial role in ensuring that the final product meets quality standards while optimizing production efficiency.

3. Benefits of China PVC Pipe Extrusion Production Line

- High Efficiency and Productivity

The China PVC pipe extrusion production line is designed for continuous operation, allowing for high output rates. This efficiency is achieved through:

- Automated processes that reduce manual labor.

- Advanced control systems that synchronize different stages of production.

- Cost-Effectiveness

Using PVC as a raw material is economically advantageous due to its low cost compared to other materials like metal or concrete. Additionally, the automation in Chinese production lines minimizes labor costs and reduces waste, further enhancing profitability.

- Versatility in Applications

PVC pipes produced through this extrusion process are suitable for various applications, including:

- Water supply systems

- Irrigation

- Drainage

- Electrical conduits

This versatility makes them an ideal choice for different industries.

- Durability and Longevity

Pipes manufactured from PVC exhibit excellent resistance to corrosion, chemicals, and environmental factors. This durability ensures a longer lifespan for installations, reducing maintenance costs over time.

- Lightweight Nature

PVC pipes are significantly lighter than traditional materials like metal or concrete. This characteristic simplifies handling, transportation, and installation processes, leading to faster project completion times.

- Environmental Benefits

The use of PVC pipes contributes to sustainable practices in construction and infrastructure development. They are recyclable and can be reprocessed into new products, minimizing waste in landfills.

4. Technological Advancements in Extrusion Lines

China's investment in research and development has led to significant advancements in extrusion technology:

- Computer-Aided Design (CAD): Enhances the precision of die designs for uniform material distribution.

- Real-Time Monitoring Systems: Allow for immediate adjustments during production to maintain quality standards.

- Material Formulation Innovations: Developments in PVC formulations improve processing efficiency and product performance.

These innovations ensure that the China PVC pipe extrusion production line remains competitive on a global scale.

5. Conclusion

The China PVC pipe extrusion production line offers numerous benefits, including high efficiency, cost-effectiveness, versatility, durability, lightweight characteristics, and environmental sustainability. As technology continues to evolve, these production lines will likely become even more advanced, further solidifying China's position as a leader in the global market for PVC pipe manufacturing.

FAQ

1. What types of pipes can be produced using a China PVC pipe extrusion production line?

The China PVC pipe extrusion production line can produce various types of pipes for applications such as water supply systems, irrigation systems, drainage solutions, and electrical conduits.

2. How does automation improve the efficiency of the PVC pipe extrusion process?

Automation reduces manual labor requirements, minimizes errors during production, synchronizes operations across different stages, and enhances overall output rates.

3. Are there environmental benefits associated with using PVC pipes?

Yes, PVC pipes are recyclable and can be reprocessed into new products, contributing to sustainable practices by reducing waste in landfills.

4. What are some key technological advancements in modern PVC pipe extrusion lines?

Key advancements include computer-aided design (CAD) for precise die designs, real-time monitoring systems for quality control, and improved material formulations for better processing efficiency.

5. Why is China a leader in PVC pipe extrusion technology?

China's leadership in this field is due to significant investments in manufacturing capabilities, technological advancements, cost-effective production methods, and a growing domestic market demand for plastic pipes across various industries.

Citations:

[1] https://www.jwellextrusions.com/the-characteristics-of-pvc-pipe-extrusion-production-line-and-the-formation-of-extrusion-touch.html

[2] https://www.youtube.com/watch?v=KMsCEDwKl28

[3] https://jieyatwinscrew.com/blog/pvc-pipe-extruder-machine/

[4] https://trustymachine.en.made-in-china.com/product-group/selJPCyrHpUt/PVC-Pipe-Extrusion-line-1.html

[5] https://www.jwellextrusions.com/function-introduction-of-pvc-pipe-extrusion-line.html

[6] https://www.youtube.com/watch?v=Hc8uH3lth1s

[7] https://www.qiangshengplas.com/news/introduction-key-features-and-applications-of-china-plastic-pipe-extrusion-line/

[8] https://www.youtube.com/watch?v=H5dHDd2u6-A

[9] https://www.verifiedmarketresearch.com/product/plastic-pipe-extrusion-production-line-market/

[10] https://www.youtube.com/watch?v=7ihRBuS9U10

[11] https://www.youtube.com/watch?v=yQj6X4Ceq24