Content Menu

● Introduction to Plastic Extrusion Machinery

>> Technical Features of China Plastic Extrusion Machinery

● Advantages of China Plastic Extrusion Machinery

>> 1. Efficiency and Speed

>> 2. Cost-Effectiveness

>> 3. Environmental Benefits

>> 4. Customization and Flexibility

>> 5. Consistent Quality

● Applications of China Plastic Extrusion Machinery

● Leading Manufacturers of China Plastic Extrusion Machinery

● Market Trends and Future Outlook

● Challenges and Opportunities

● Conclusion

● FAQs

>> 1. What is the main function of plastic extrusion machinery?

>> 2. How does China plastic extrusion machinery contribute to environmental sustainability?

>> 3. What types of industries benefit from using China plastic extrusion machinery?

>> 4. What are the key technical features of China plastic extrusion machinery?

>> 5. How does China plastic extrusion machinery enhance production efficiency?

● Citations:

The plastic extrusion industry in China has experienced significant growth over the years, driven by advancements in technology and the increasing demand for high-quality plastic products. China plastic extrusion machinery has become a cornerstone in the global manufacturing sector, offering numerous benefits that make it a preferred choice for industries worldwide. This article will delve into the key advantages of China plastic extrusion machinery, exploring its efficiency, versatility, cost-effectiveness, and environmental benefits.

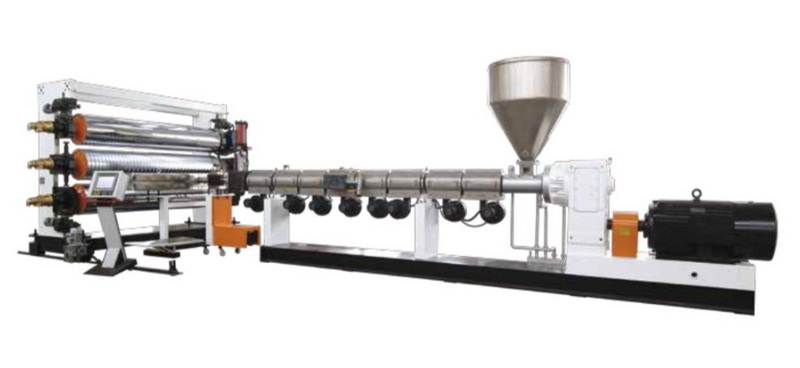

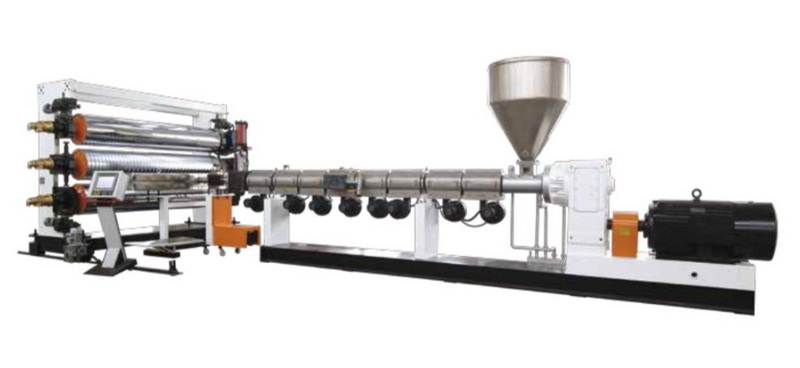

Introduction to Plastic Extrusion Machinery

Plastic extrusion is a process that involves melting plastic material and shaping it into a continuous profile. This process is highly efficient and can produce a wide range of products, from simple pipes and tubes to complex profiles and sheets. China plastic extrusion machinery is designed to optimize this process, ensuring high-quality output with minimal waste.

Technical Features of China Plastic Extrusion Machinery

China plastic extrusion machinery is characterized by its advanced technical features, which include:

- Modular Design: Modular production allows for customization and flexibility, enabling manufacturers to adapt machines to specific production needs. This modularity also helps in reducing development cycles and costs. For instance, manufacturers like JWELL Machinery have adopted modular production methods to meet diverse customer requirements[4].

- High Efficiency: These machines are designed for high output and low energy consumption, making them cost-effective and environmentally friendly. The use of advanced technologies such as high-torque gearboxes enhances their efficiency and durability[4].

- Versatility: They can process a wide variety of plastic materials, including thermoplastics and biodegradable plastics, allowing for diverse product offerings. This versatility is crucial in meeting the varied demands of industries such as construction, packaging, and automotive[2][3].

Advantages of China Plastic Extrusion Machinery

1. Efficiency and Speed

China plastic extrusion machinery is renowned for its ability to produce large volumes of plastic products quickly and efficiently. This high-speed production capability is crucial for meeting tight deadlines and maintaining competitiveness in the market. The machines are capable of continuous operation, reducing downtime and increasing overall productivity[1][2].

2. Cost-Effectiveness

The cost-effectiveness of China plastic extrusion machinery is another significant advantage. By reducing labor costs and minimizing waste, these machines help manufacturers lower their overall production costs. Additionally, the ability to produce high-quality products at lower costs makes them more competitive in the global market[6].

3. Environmental Benefits

The use of China plastic extrusion machinery also offers environmental benefits. These machines are designed to be energy-efficient and reduce waste, making them a more sustainable choice for manufacturing. The recycling capabilities of some machines further enhance their eco-friendliness by reducing plastic waste[3][4].

4. Customization and Flexibility

Manufacturers can customize China plastic extrusion machinery to meet specific production requirements. This flexibility allows for the production of a wide range of products with varying textures and colors. Modular designs enable easy modification and adaptation to different production needs, ensuring that manufacturers can quickly respond to market changes[4].

5. Consistent Quality

These machines ensure consistent product quality by maintaining uniform thickness and shape throughout the production process. This consistency is crucial for meeting industry standards and customer expectations. The advanced control systems in these machines ensure that products meet precise specifications, reducing the need for rework and improving overall efficiency[2].

Applications of China Plastic Extrusion Machinery

China plastic extrusion machinery is widely used across various industries, including:

- Construction: For producing pipes, tubes, and profiles used in plumbing and electrical systems. The demand for durable and affordable plastic products in construction drives the growth of the plastic extrusion machine market in China[3].

- Packaging: For manufacturing plastic films and sheets used in packaging products. The rise in e-commerce has led to higher demand for plastic packaging, such as films, containers, and bottles[3].

- Automotive: For producing lightweight plastic components that improve fuel efficiency. The automotive industry's shift towards lightweight materials has increased the need for plastic extrusion machines capable of producing durable plastic parts[3][5].

Leading Manufacturers of China Plastic Extrusion Machinery

Some of the prominent manufacturers of China plastic extrusion machinery include:

- JWELL Machinery: Known for its high-quality extrusion lines and innovative technologies. JWELL's machines are designed to meet the diverse needs of the global market, with a focus on efficiency and customization[2][4].

- USEON: Specializes in providing a wide range of extrusion solutions, catering to various industries. USEON's machines are recognized for their reliability and versatility in processing different plastic materials[2].

- Cowin Extrusion: Offers advanced extrusion technology with a focus on high-performance applications. Cowin's machines are designed to enhance production efficiency and product quality[2].

Market Trends and Future Outlook

The plastic extrusion machine market is experiencing significant growth, driven by increasing demand across various regions. China holds the largest share in the market, with other countries like Brazil, India, and South Korea showing high growth rates[3]. The focus on sustainability and environmental friendliness is driving innovation in the industry, with manufacturers developing machines capable of processing recycled plastics and biodegradable materials[3][5].

Technological advancements are also playing a crucial role in the market's growth. Modern plastic extrusion machines are designed with energy-saving features, making them more efficient in terms of energy consumption compared to older models[2][5]. The integration of advanced technologies such as modular production and high-torque gearboxes further enhances the efficiency and durability of these machines[4].

Challenges and Opportunities

Despite the growth and advantages of China plastic extrusion machinery, the industry faces several challenges. Environmental concerns and regulatory restrictions are significant challenges that manufacturers must address. However, these challenges also present opportunities for innovation and growth. The development of environmentally friendly machines and sustainable production processes can help mitigate these challenges while enhancing the industry's competitiveness[7].

The increasing demand for plastic products globally, coupled with advancements in technology, provides a promising outlook for the future of China plastic extrusion machinery. As manufacturers continue to innovate and improve efficiency, the market is expected to expand further, with China remaining a major player in the global plastic extrusion machine market[3][7].

Conclusion

In conclusion, China plastic extrusion machinery offers a multitude of benefits that make it a preferred choice for manufacturers worldwide. Its efficiency, cost-effectiveness, environmental sustainability, customization options, and consistent product quality are just a few of the advantages that set it apart. As the demand for high-quality plastic products continues to rise, the importance of China plastic extrusion machinery in meeting this demand will only grow.

FAQs

1. What is the main function of plastic extrusion machinery?

Plastic extrusion machinery is used to shape plastic materials into continuous profiles, sheets, films, and various other forms by forcing melted plastic through a die[2].

2. How does China plastic extrusion machinery contribute to environmental sustainability?

China plastic extrusion machinery contributes to environmental sustainability by being energy-efficient and minimizing waste during production, making it a more eco-friendly option compared to traditional manufacturing methods[3][4].

3. What types of industries benefit from using China plastic extrusion machinery?

Industries such as construction, packaging, and automotive benefit significantly from using China plastic extrusion machinery for producing essential components like pipes, packaging materials, and vehicle parts[3][5].

4. What are the key technical features of China plastic extrusion machinery?

Key technical features include modular design, high efficiency, versatility in processing different plastic materials, and advanced control systems that ensure consistent product quality[2][4].

5. How does China plastic extrusion machinery enhance production efficiency?

China plastic extrusion machinery enhances production efficiency by allowing for high-speed production, reducing labor costs, and minimizing material waste, which together contribute to faster and more cost-effective manufacturing processes[1][2].

Citations:

[1] https://www.redsungearbox.com/news/china-plastic-extrusion-machine-manufacturers-suppliers-and-factory/

[2] https://www.sourcifychina.com/plastic-extrusion-machine-guide-in-depth/

[3] https://www.futuremarketinsights.com/reports/plastic-extrusion-machine-market

[4] https://www.jwellmachine.com/development-and-breakthrough-of-china-plastic-extrusion-machine/

[5] https://www.alliedmarketresearch.com/plastic-extrusion-machine-market

[6] https://www.jwellmachine.com/popular-china-plastic-extrusion-machine-dominates-the-global-market/

[7] https://mobilityforesights.com/product/china-plastic-extrusion-machines-market/

[8] https://www.beierplas.com/extrusion-machinery/plastic-profile-extrusion-line/

[9] https://www.puruimachinery.com/plastic-extrusion-machinery/

[10] https://www.redsungearbox.com/china-twin-screw-extruder-and-plastic-extrusion-machinery/

[11] https://www.grandviewresearch.com/horizon/outlook/plastic-extrusion-machinery-market/china

[12] https://www.6wresearch.com/industry-report/china-plastic-extrusion-machines-market-outlook

[13] https://www.grandviewresearch.com/horizon/outlook/extrusion-machinery-market/china

[14] https://www.blessonextrusion.com/advantages-of-pvc-pipe-extrusion-line/