Content Menu

● Introduction

● Understanding Aluminum Extrusion Technology

>> Key Components of an Extrusion Press

● Benefits of Investing in Used Equipment

● Maintenance and Operation

● Applications and Industries

>> Production Capabilities

● Selection Criteria

● Technology Integration

● Environmental Considerations

● Future Trends

● Conclusion

● Frequently Asked Questions

>> Q1: What is the typical lifespan of a Used Aluminum Extrusion Press?

>> Q2: How does the cost of a used press compare to new equipment?

>> Q3: What are the key maintenance requirements?

>> Q4: Can a Used Aluminum Extrusion Press be upgraded?

>> Q5: What should buyers check before purchasing?

Introduction

The Used Aluminum Extrusion Press industry has become increasingly significant in modern manufacturing, offering cost-effective solutions for businesses looking to enhance their production capabilities. This comprehensive guide explores the various aspects of used aluminum extrusion equipment, from technical specifications to practical applications.

Understanding Aluminum Extrusion Technology

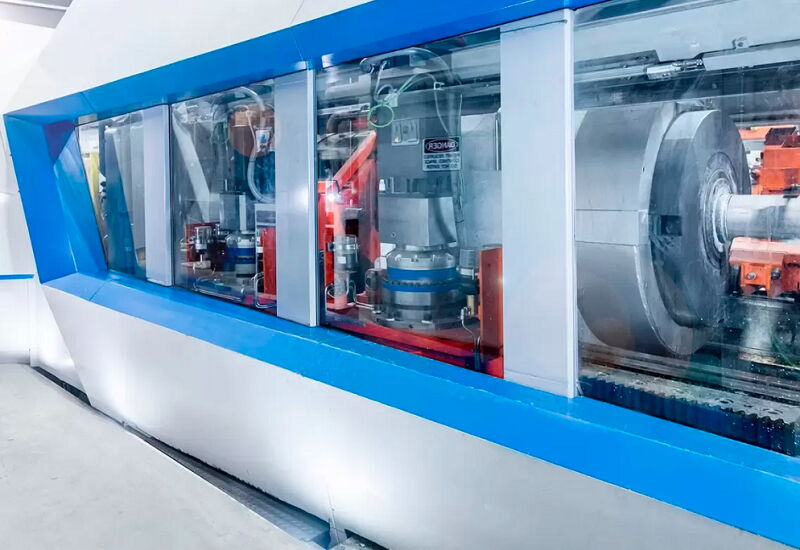

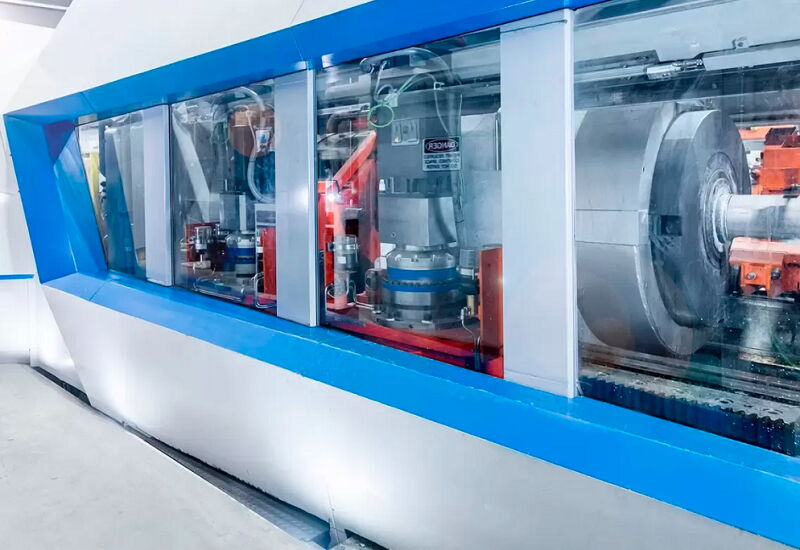

A Used Aluminum Extrusion Press represents a significant investment in manufacturing capability. These machines are designed to transform aluminum billets into precise profiles through a controlled extrusion process. The technology behind these systems has evolved significantly, making even pre-owned equipment a viable option for many businesses.

Key Components of an Extrusion Press

Modern Used Aluminum Extrusion Press systems typically include:

- Main cylinder and ram

- Container and liner

- Die holder and die

- Handling systems

- Control systems

- Cooling mechanisms

Benefits of Investing in Used Equipment

Choosing a Used Aluminum Extrusion Press offers numerous advantages:

- Cost-effectiveness

- Immediate availability

- Proven performance history

- Lower initial investment

- Faster return on investment

- Access to established technology

Maintenance and Operation

Proper maintenance of a Used Aluminum Extrusion Press is crucial for optimal performance. Regular maintenance procedures include:

- Hydraulic system checks

- Die maintenance

- Container liner inspection

- Ram alignment verification

- Control system updates

- Safety system testing

Applications and Industries

Used Aluminum Extrusion Press equipment serves various industries:

- Construction

- Automotive manufacturing

- Aerospace

- Solar energy

- Transportation

- Consumer goods

- Industrial machinery

Production Capabilities

Modern Used Aluminum Extrusion Press systems can handle:

- Complex profile designs

- Various alloy types

- Different production volumes

- Multiple finish options

- Custom specifications

- Precision tolerances

Selection Criteria

When choosing a Used Aluminum Extrusion Press, consider:

- Press capacity and size

- Hydraulic system condition

- Control system technology

- Maintenance history

- Available documentation

- Manufacturer reputation

- Support availability

Technology Integration

Modern Used Aluminum Extrusion Press systems often feature:

- Digital control systems

- Automated handling

- Quality monitoring

- Production tracking

- Energy management

- Safety interlocks

Environmental Considerations

Using a Used Aluminum Extrusion Press contributes to sustainability through:

- Reduced resource consumption

- Energy efficiency

- Material recycling

- Waste minimization

- Extended equipment lifecycle

- Smaller carbon footprint

Future Trends

The Used Aluminum Extrusion Press market is evolving with:

- Smart manufacturing integration

- Enhanced automation

- Improved energy efficiency

- Advanced control systems

- Better material handling

- Increased productivity

Conclusion

The Used Aluminum Extrusion Press market continues to provide valuable opportunities for manufacturers seeking to enhance their production capabilities. With proper research, maintenance, and operation, these systems can deliver excellent return on investment while supporting sustainable manufacturing practices.

Frequently Asked Questions

Q1: What is the typical lifespan of a Used Aluminum Extrusion Press?

A1: With proper maintenance and regular updates, a Used Aluminum Extrusion Press can operate effectively for 20-30 years. The actual lifespan depends on usage patterns, maintenance quality, and operating conditions.

Q2: How does the cost of a used press compare to new equipment?

A2: A Used Aluminum Extrusion Press typically costs 40-60% less than new equipment, making it an attractive option for businesses looking to expand their production capabilities while managing costs.

Q3: What are the key maintenance requirements?

A3: Essential maintenance includes regular hydraulic system checks, die maintenance, alignment verification, and control system updates. A comprehensive maintenance schedule should be followed to ensure optimal performance.

Q4: Can a Used Aluminum Extrusion Press be upgraded?

A4: Yes, most Used Aluminum Extrusion Press systems can be upgraded with modern control systems, automation features, and safety equipment to improve performance and efficiency.

Q5: What should buyers check before purchasing?

A5: Important factors include operational history, maintenance records, hydraulic system condition, control system status, available documentation, and the reputation of both the original manufacturer and the seller.