Content Menu

● Understanding Aluminum and Fire Hazards

● Regulatory Frameworks Governing Fire Safety

● Essential Fire Safety Measures

>> 1. Comprehensive Fire Safety Plans

>> 2. Installation of Fire Suppression Systems

>> 3. Proper Ventilation

>> 4. Regular Maintenance and Housekeeping

● Personal Protective Equipment (PPE)

● Best Practices for Safe Operations

● Training and Awareness Programs

● Incident Reporting Procedures

● Role of Technology in Enhancing Fire Safety

● Collaboration with Fire Safety Experts

● Conclusion

● FAQ

>> 1. What types of fires are common in the aluminum extrusion industry?

>> 2. How can I ensure proper ventilation in my facility?

>> 3. What kind of fire extinguishers should be used?

>> 4. Are there specific regulations for handling aluminum dust?

>> 5. How often should fire drills be conducted?

● Citations:

The aluminum extrusion industry plays a pivotal role in manufacturing various products used across multiple sectors, including construction, transportation, and consumer goods. However, with the benefits of aluminum come inherent fire risks that necessitate stringent fire safety standards. This article delves into the fire safety standards applicable to the aluminum extrusion industry, exploring preventive measures, regulatory frameworks, and best practices to ensure a safe working environment.

Understanding Aluminum and Fire Hazards

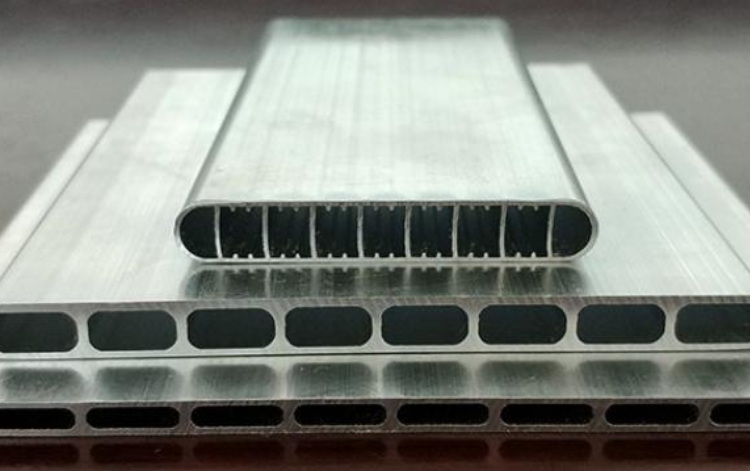

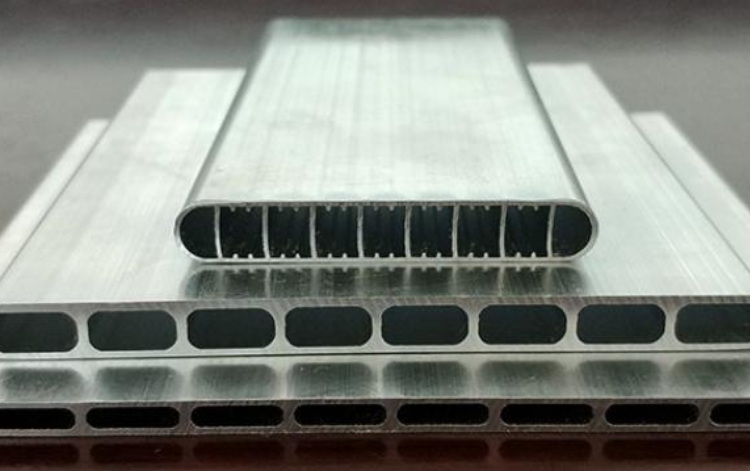

Aluminum is generally considered a non-combustible material; however, it can pose significant fire hazards under certain conditions. When finely divided or in molten form, aluminum can ignite and cause fires or explosions. The risks are heightened during processes like welding, cutting, and machining, where sparks and heat are prevalent.

Key Fire Hazards in Aluminum Extrusion:

- Sparks from Welding and Cutting: These can ignite flammable materials nearby.

- Dust Accumulation: Aluminum dust is combustible and can lead to dust deflagration if not managed properly.

- Molten Aluminum Spills: These can cause severe burns and ignite surrounding materials.

Regulatory Frameworks Governing Fire Safety

Various organizations set forth guidelines and regulations that govern fire safety in the aluminum extrusion industry. These include:

- National Fire Protection Association (NFPA): The NFPA provides standards such as NFPA 484, which addresses the fire hazards of aluminum dust.

- Occupational Safety and Health Administration (OSHA): OSHA mandates safe work practices to reduce fire risks associated with metalworking operations.

- American National Standards Institute (ANSI): ANSI standards often complement NFPA guidelines to ensure comprehensive safety measures.

Essential Fire Safety Measures

To mitigate fire risks in the aluminum extrusion industry, several safety measures should be adopted:

1. Comprehensive Fire Safety Plans

Every facility should have a detailed fire safety plan that includes:

- Regular Training: Employees must be trained on fire safety protocols, including how to use fire extinguishers effectively.

- Emergency Evacuation Procedures: Clear procedures should be established for evacuating personnel in case of a fire.

- Fire Drills: Conducting regular fire drills ensures that employees are familiar with emergency protocols.

2. Installation of Fire Suppression Systems

Effective fire suppression systems are crucial for minimizing damage during a fire incident. Key components include:

- Automatic Sprinkler Systems: These systems activate when a certain temperature is reached, helping to control or extinguish fires quickly.

- Class D Fire Extinguishers: Specifically designed for metal fires, these extinguishers are essential in areas where aluminum is processed.

3. Proper Ventilation

Good ventilation is vital to prevent the accumulation of flammable gases and fumes generated during machining processes.

- Local Exhaust Ventilation Systems: These systems capture harmful airborne particles at their source, protecting workers from respiratory hazards.

4. Regular Maintenance and Housekeeping

Maintaining a clean workspace is critical in preventing fires:

- Dust Control: Regularly clean areas where aluminum dust may accumulate to reduce combustion risks.

- Equipment Maintenance: Ensure that machines are well-maintained to prevent overheating and potential ignition sources.

Personal Protective Equipment (PPE)

The use of appropriate PPE is essential for worker safety in the aluminum extrusion industry. Workers should wear:

- Fire-resistant Clothing: This protects against burns from sparks or molten aluminum.

- Safety Goggles: To shield eyes from flying particles during cutting or grinding processes.

- Respirators: Necessary when working in environments with hazardous fumes or dust.

Best Practices for Safe Operations

Implementing best practices can significantly enhance fire safety in aluminum extrusion facilities:

- Conduct Risk Assessments: Regularly assess potential fire hazards in the workplace and implement corrective actions.

- Establish Material Handling Protocols: Properly handle and store flammable materials away from heat sources.

- Monitor Work Processes: Ensure that all processes involving heat generation are closely monitored for any signs of overheating or ignition.

Training and Awareness Programs

Training programs are vital for instilling a culture of safety within the workplace. These programs should cover:

- Fire Safety Education: Employees should learn about the specific fire hazards associated with aluminum extrusion processes and how to mitigate them effectively.

- Emergency Response Training: Workers must understand their roles during an emergency, including how to use firefighting equipment correctly and how to assist others during an evacuation.

Incident Reporting Procedures

Establishing clear incident reporting procedures is essential for continuous improvement in safety standards:

- Encourage Reporting: Employees should feel empowered to report near misses or unsafe conditions without fear of reprisal.

- Investigate Incidents Thoroughly: Conduct thorough investigations into any incidents or near misses to identify root causes and implement corrective actions promptly.

Role of Technology in Enhancing Fire Safety

Advancements in technology have significantly improved safety measures within the aluminum extrusion industry:

- Fire Detection Systems: Modern systems utilize advanced sensors that can detect heat or smoke early, allowing for quicker responses to potential fires.

- Automated Dust Collection Systems: These systems not only improve air quality but also reduce the risk of dust explosions by minimizing dust accumulation in work areas.

Collaboration with Fire Safety Experts

Engaging with fire safety experts can provide valuable insights into enhancing safety protocols:

- Regular Audits: Conducting audits with external experts can help identify vulnerabilities within existing safety measures.

- Customized Training Programs: Experts can tailor training programs specific to the unique challenges faced by an aluminum extrusion facility.

Conclusion

Fire safety in the aluminum extrusion industry is paramount due to the unique hazards associated with working with this material. By adhering to established regulations, implementing comprehensive safety measures, fostering a culture of safety among employees, and leveraging technology, companies can significantly reduce the risk of fire incidents. Continuous training and awareness are critical components of an effective fire safety strategy that not only protects workers but also safeguards valuable assets and ensures operational continuity.

FAQ

1. What types of fires are common in the aluminum extrusion industry?

Fires in the aluminum extrusion industry typically arise from sparks generated during welding or cutting processes, as well as from combustible aluminum dust accumulation.

2. How can I ensure proper ventilation in my facility?

Implement local exhaust ventilation systems to capture harmful fumes at their source and ensure general ventilation is adequate throughout the workspace.

3. What kind of fire extinguishers should be used?

Class D fire extinguishers are specifically designed for metal fires and should be readily available in areas where aluminum is processed.

4. Are there specific regulations for handling aluminum dust?

Yes, OSHA and NFPA provide guidelines on managing combustible dust hazards, including regular cleaning protocols and employee training on dust control measures.

5. How often should fire drills be conducted?

Fire drills should be conducted at least twice a year to ensure all employees are familiar with evacuation procedures and emergency protocols.

Citations:

[1] https://www.austgen.com.au/what-safety-precautions-are-crucial-during-aluminum-fabrication-processes/

[2] https://www.chaluminium.com/what-are-the-safety-considerations-for-working-with-aluminum-multi-port-extrusions

[3] https://axaxl.com/-/media/axaxl/files/pdfs/prc-guidelines/prc-17/prc17130aluminumindustryabstractv1.pdf?sc_lang=en&hash=9686E8ED795CA35B7B96403CF7B5D715

[4] https://www.decorativeimaging.com.au/news/which-types-of-aluminium-cladding-are-fire-safe/

[5] https://www.mecalux.com/logistics-items/fire-protection-measures-for-metal-racks-and-warehouses

[6] https://gtoaluminum.com/alumminum-cladding-resistance/

[7] https://www.hydro.com/globalassets/01-products--services/extruded-profiles/americas/ena-resources/safety-data-sheets/2-509-6xxx-annodized-aluminum-parts.pdf

[8] https://www.outashi.com/blog/safety-precautions-in-operating-aluminum-extrusion-machine-id35.html