Content Menu

● Introduction

● Understanding Aluminum Extrusion Accessories

● Key Accessories for Aluminum Extrusions

>> T-Slot Connectors

>> Brackets and Supports

>> Fasteners and Hardware

>> Modular Systems

>> Custom Aluminum Extrusions

● Choosing the Right Accessories for Your Project

● Applications of Aluminum Extrusion Accessories

● Conclusion

● Related Questions

>> 1. What types of aluminum extrusion accessories are available?

>> 2. How do I choose the right fasteners for my aluminum extrusion project?

>> 3. Can I use aluminum extrusion accessories in outdoor applications?

>> 4. What are the benefits of using modular aluminum systems?

>> 5. How can custom aluminum extrusions improve my project?

Introduction

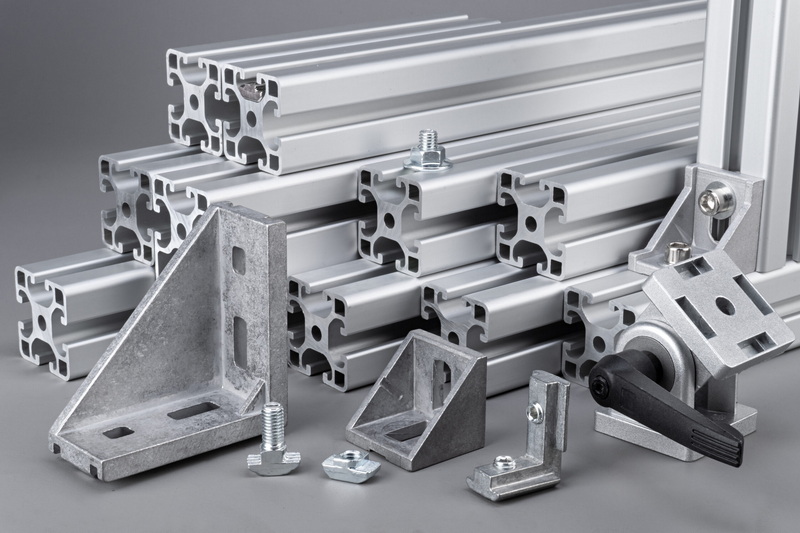

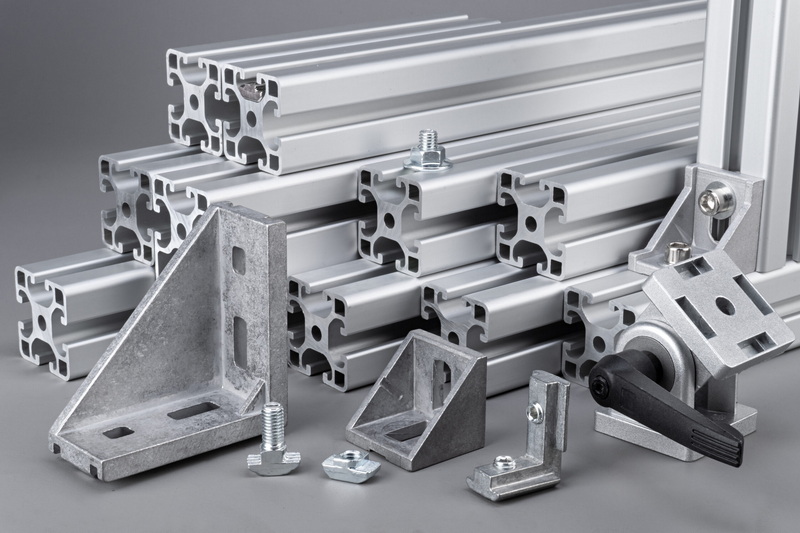

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This versatile method is widely used in various industries, including construction, automotive, and electronics, due to aluminum's lightweight, strength, and corrosion resistance. However, to maximize the potential of aluminum extrusions, it is essential to utilize the right aluminum extrusion accessories. These accessories not only enhance the functionality of the extrusions but also ensure structural integrity and ease of assembly. In this article, we will explore the essential aluminum extrusion accessories that can elevate your next project.

Understanding Aluminum Extrusion Accessories

Aluminum extrusion accessories are components that complement aluminum profiles, providing support, connection, and assembly capabilities. These accessories come in various forms, including connectors, brackets, fasteners, and specialized hardware. They are typically made from high-quality aluminum or other durable materials to ensure longevity and reliability in various applications.

The importance of these accessories cannot be overstated. They play a crucial role in the assembly process, allowing for quick and efficient construction of structures, frames, and systems. By selecting the right accessories, you can enhance the performance and aesthetics of your aluminum extrusion projects.

Key Accessories for Aluminum Extrusions

T-Slot Connectors

T-slot connectors are one of the most essential aluminum extrusion accessories. These connectors are designed to fit into the T-slots of aluminum profiles, allowing for easy assembly and disassembly of structures. They come in various shapes and sizes, including corner connectors, flat connectors, and angle connectors.

The primary benefit of using T-slot connectors is their versatility. They enable users to create complex structures with minimal tools and effort. Additionally, T-slot connectors provide a strong and stable connection, ensuring that the assembled structure can withstand various loads and stresses.

Brackets and Supports

Brackets and supports are crucial for providing structural integrity to aluminum extrusion assemblies. There are several types of brackets available, including corner brackets, mounting brackets, and support brackets. Each type serves a specific purpose, depending on the design and requirements of the project.

Corner brackets are commonly used to reinforce joints between two aluminum profiles, ensuring a strong connection. Mounting brackets allow for the attachment of additional components, such as shelves or panels, to the aluminum frame. Support brackets are essential for stabilizing longer spans, preventing sagging or bending under load.

Using the right brackets and supports can significantly enhance the durability and stability of your aluminum extrusion projects.

Fasteners and Hardware

Fasteners and hardware are vital components in any aluminum extrusion assembly. They include screws, nuts, bolts, and washers, which are used to secure various parts together. The choice of fasteners is critical, as they must be compatible with the aluminum profiles and capable of handling the expected loads.

When selecting fasteners, consider factors such as material, size, and thread type. Stainless steel fasteners are often recommended for their corrosion resistance and strength. Additionally, using the correct size and type of fastener ensures a secure and stable connection, reducing the risk of failure in the assembly.

Modular Systems

Modular aluminum systems are designed to provide flexibility and adaptability in various applications. These systems consist of pre-engineered components that can be easily assembled and reconfigured as needed. Modular systems are particularly popular in industries such as manufacturing, warehousing, and retail, where space and layout requirements may change frequently.

The primary advantage of modular aluminum systems is their ease of use. They allow for quick assembly and disassembly, making it simple to adapt to changing needs. Additionally, these systems often incorporate various aluminum extrusion accessories, enhancing their functionality and versatility.

Custom Aluminum Extrusions

Custom aluminum extrusions are tailored to meet specific project requirements. These extrusions can be designed to accommodate unique shapes, sizes, and features, making them ideal for specialized applications. When combined with the right aluminum extrusion accessories, custom extrusions can create highly efficient and effective solutions.

Working with a manufacturer that offers custom aluminum extrusions allows you to optimize your design and ensure that all components fit together seamlessly. This can lead to improved performance and reduced assembly time, ultimately saving costs in the long run.

Choosing the Right Accessories for Your Project

When selecting aluminum extrusion accessories for your project, several factors should be considered to ensure compatibility and performance. Here are some key considerations:

- Load Capacity: Assess the expected loads and stresses that the assembly will encounter. Choose accessories that can handle these loads without compromising structural integrity.

- Environmental Conditions: Consider the environment in which the assembly will be used. If it will be exposed to moisture or corrosive substances, opt for corrosion-resistant materials, such as stainless steel or anodized aluminum.

- Compatibility: Ensure that the accessories you choose are compatible with the specific aluminum profiles you are using. This includes checking dimensions, slot sizes, and connection types.

- Ease of Assembly: Look for accessories that facilitate quick and easy assembly. This can save time and labor costs during the construction process.

- Aesthetics: If the appearance of the assembly is important, consider how the accessories will impact the overall look. Choose accessories that complement the design of the aluminum profiles.

Applications of Aluminum Extrusion Accessories

Aluminum extrusion accessories are used in a wide range of industries and applications. Here are some examples:

- Automotive Industry: Aluminum extrusions are commonly used in vehicle frames, body panels, and structural components. Accessories such as brackets and fasteners are essential for assembling these parts securely.

- Construction: In construction, aluminum extrusions are used for window frames, curtain walls, and structural supports. Accessories play a crucial role in ensuring the stability and durability of these structures.

- Robotics: Aluminum extrusion accessories are widely used in robotics for building frames and supports for robotic arms and other components. The lightweight nature of aluminum allows for efficient movement and operation.

- Retail Displays: Many retail environments utilize aluminum extrusions for display fixtures and shelving. Accessories such as connectors and brackets help create attractive and functional displays.

- Industrial Equipment: In manufacturing and industrial settings, aluminum extrusions are used for machine frames, workstations, and conveyor systems. Accessories are essential for assembling these systems efficiently.

Conclusion

In conclusion, aluminum extrusion accessories are essential components that enhance the functionality, stability, and efficiency of aluminum profiles in various applications. By understanding the different types of accessories available and how to choose the right ones for your project, you can significantly improve the performance of your aluminum extrusion assemblies. Whether you are working in construction, automotive, robotics, or any other industry, investing in high-quality aluminum extrusion accessories will lead to better results and greater satisfaction in your projects.

Related Questions

1. What types of aluminum extrusion accessories are available?

Aluminum extrusion accessories include T-slot connectors, brackets, supports, fasteners, and modular systems. Each type serves a specific purpose in enhancing the functionality and stability of aluminum profiles.

2. How do I choose the right fasteners for my aluminum extrusion project?

When selecting fasteners, consider factors such as material, size, and thread type. Stainless steel fasteners are often recommended for their strength and corrosion resistance.

3. Can I use aluminum extrusion accessories in outdoor applications?

Yes, aluminum extrusion accessories can be used in outdoor applications, but it is essential to choose corrosion-resistant materials to withstand environmental conditions.

4. What are the benefits of using modular aluminum systems?

Modular aluminum systems offer flexibility and adaptability, allowing for quick assembly and reconfiguration as needed. They are ideal for industries where space and layout requirements may change frequently.

5. How can custom aluminum extrusions improve my project?

Custom aluminum extrusions are tailored to meet specific project requirements, allowing for optimized designs and seamless integration with accessories, ultimately improving performance and reducing assembly time.