Content Menu

● Understanding Aluminum Extrusion

>> Aluminum Extrusion Process

● Infinite Recyclability

● Energy Efficiency

● Reduced Waste Generation

● Corrosion Resistance

● Contribution to Renewable Energy Solutions

● Role in Sustainable Construction

● Economic Benefits Tied to Environmental Sustainability

● Challenges Facing Aluminum Extrusion

● Conclusion

● FAQ

>> 1. What is aluminum extrusion?

>> 2. Why is aluminum considered environmentally friendly?

>> 3. How does recycling aluminum benefit the environment?

>> 4. What applications benefit from using aluminum extrusions?

>> 5. How does using aluminum reduce carbon emissions?

● Citations:

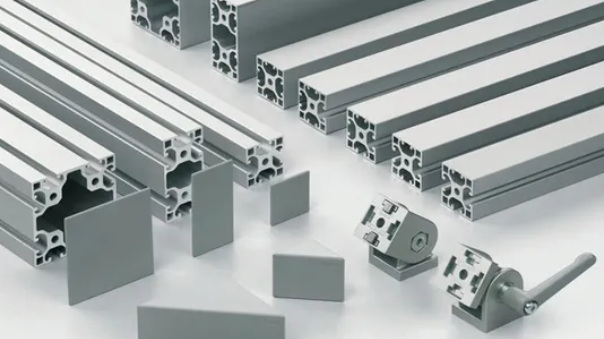

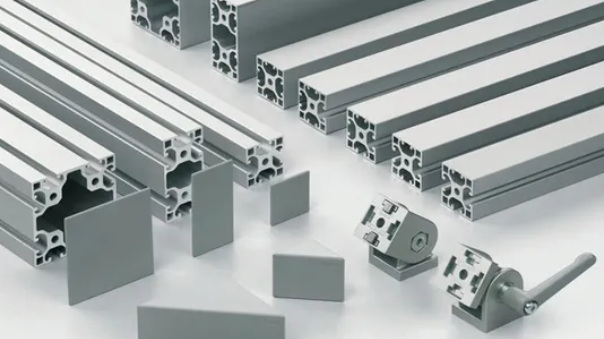

Aluminum extrusion is a manufacturing process that shapes aluminum into specific profiles by forcing it through a die. This method is not only efficient but also offers numerous environmental benefits, making aluminum extrusion material a sustainable choice for various industries. In this article, we will explore the various environmental advantages of using aluminum extrusion, including its recyclability, energy efficiency, and its role in reducing greenhouse gas emissions.

Understanding Aluminum Extrusion

Aluminum extrusion involves heating aluminum billets until they are malleable and then pushing them through a die to create desired shapes. This process can produce a wide variety of profiles, from simple bars to complex shapes used in construction and manufacturing. The versatility of aluminum extrusions allows for their application in diverse industries, including automotive, aerospace, construction, and renewable energy.

Aluminum Extrusion Process

The aluminum extrusion process can be broken down into several key steps:

1. Billet Preparation: Aluminum billets are preheated to a specific temperature to enhance their malleability.

2. Extrusion: The heated billet is placed in an extruder, where it is forced through a die under high pressure.

3. Cooling: After exiting the die, the extruded aluminum is cooled using air or water to solidify it into the desired shape.

4. Cutting and Finishing: The extruded profiles are cut to length and may undergo additional finishing processes such as anodizing or painting for enhanced durability and aesthetics.

This efficient production method not only conserves material but also allows for complex designs that can be tailored to specific applications.

Infinite Recyclability

One of the most significant environmental benefits of aluminum extrusion material is its infinite recyclability. Unlike many other materials that degrade when recycled, aluminum can be melted down and reused indefinitely without losing its inherent properties.

- Energy Savings: Recycling aluminum requires only about 5% of the energy needed for primary production. This drastic reduction in energy consumption translates into lower greenhouse gas emissions.

- Resource Conservation: By using recycled aluminum for extrusions, the demand for virgin materials is reduced, conserving natural resources and minimizing environmental degradation associated with mining activities.

- Closed-Loop Recycling: Many industries utilize closed-loop recycling systems where scrap aluminum from production processes is collected and reused in new products. This practice not only reduces waste but also ensures that the material remains within the manufacturing cycle.

Energy Efficiency

Aluminum extrusion is known for its energy efficiency throughout its lifecycle:

- Low Energy Consumption: The lightweight nature of aluminum means that products made from it require less energy to transport. For example, vehicles made with aluminum components consume less fuel due to their reduced weight.

- Thermal Efficiency: Aluminum has excellent thermal conductivity, which makes it ideal for applications like window frames and heat sinks. This property helps buildings maintain temperature more efficiently, reducing heating and cooling costs.

- Reflectivity: Aluminum's reflective properties can contribute to energy savings in buildings by reducing the need for artificial lighting during daytime hours. This can lead to lower electricity consumption and reduced operational costs.

Reduced Waste Generation

The production of aluminum extrusions generates minimal waste compared to other materials:

- High Strength-to-Weight Ratio: Aluminum's strength allows for thinner profiles that still meet structural requirements. This means less material is used overall, leading to reduced waste during manufacturing.

- Precision Fabrication: Aluminum extrusions can be designed to exact specifications, minimizing the need for additional processing or finishing. This precision reduces scrap rates and enhances overall sustainability.

- Minimized Off-Cuts: Innovative design techniques allow manufacturers to optimize the use of materials during production, further reducing off-cuts and waste generation.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, making it highly resistant to corrosion:

- Longevity: This corrosion resistance extends the lifespan of products made from aluminum extrusions, reducing the need for replacements and further minimizing resource consumption.

- Maintenance-Free: Many aluminum products require little to no maintenance over their lifespan, which not only saves time but also reduces the environmental impact associated with upkeep.

- Reusability: Due to its durability and resistance to degradation, aluminum can often be reused in different applications without significant loss of quality or performance.

Contribution to Renewable Energy Solutions

Aluminum extrusions play a crucial role in advancing renewable energy technologies:

- Solar Panel Frames: Lightweight and durable aluminum frames support solar panels, facilitating the growth of solar energy infrastructure. The use of aluminum in solar panel manufacturing helps reduce overall system weight while maintaining structural integrity.

- Wind Turbine Components: Aluminum's strength-to-weight ratio makes it an ideal choice for constructing components used in wind turbines, further promoting sustainable energy production. The lightweight nature of aluminum helps improve turbine efficiency by allowing for larger blades without significantly increasing structural loads.

- Energy Storage Systems: Aluminum is increasingly being used in battery enclosures and components for electric vehicles (EVs) and renewable energy storage systems due to its lightweight properties and thermal management capabilities.

Role in Sustainable Construction

The construction industry has increasingly adopted aluminum extrusions due to their sustainability benefits:

- Energy-Efficient Buildings: Using aluminum in building components such as windows and facades can significantly reduce a building's energy consumption over its lifetime. The thermal performance of aluminum frames helps maintain indoor temperatures and reduces reliance on heating and cooling systems.

- Sustainable Design Practices: Architects and builders are recognizing the advantages of integrating aluminum extrusions into green building designs, contributing to LEED certification and other sustainability standards. These practices not only enhance building performance but also promote environmental stewardship within the construction industry.

- Aesthetic Versatility: Aluminum extrusions can be finished in various ways (anodizing, powder coating), allowing architects to achieve desired aesthetics while maintaining sustainability goals. This versatility enables designers to create visually appealing structures that meet modern architectural standards without compromising on environmental responsibility.

Economic Benefits Tied to Environmental Sustainability

The economic implications of using aluminum extrusion material extend beyond initial cost savings:

- Job Creation: The growth of the aluminum recycling industry creates jobs in collection, processing, and manufacturing sectors. As demand for sustainable materials increases, so does employment within these fields.

- Market Demand for Sustainable Products: Consumers are increasingly seeking products made from sustainable materials. Companies that utilize aluminum extrusion can position themselves favorably in the market by promoting their commitment to environmental responsibility.

- Long-Term Cost Savings: While initial investments in sustainable materials may be higher, long-term savings from reduced energy consumption, maintenance costs, and waste management can outweigh these costs over time.

Challenges Facing Aluminum Extrusion

Despite its numerous benefits, there are challenges associated with aluminum extrusion that must be addressed:

- Energy Intensity of Production: While recycling requires significantly less energy than primary production, the initial extraction and processing of bauxite ore into alumina remain energy-intensive processes that contribute to greenhouse gas emissions.

- Transportation Emissions: Although lightweight aluminum reduces transportation emissions compared to heavier materials like steel or concrete, transporting raw materials still contributes to carbon footprints. Local sourcing strategies can help mitigate these impacts.

- Market Volatility: Fluctuations in global demand for aluminum can affect pricing stability and availability. Companies must navigate these market dynamics while maintaining sustainable practices.

Conclusion

In conclusion, the environmental benefits of using aluminum extrusion material are substantial. From its infinite recyclability and energy efficiency to its role in reducing waste generation and supporting renewable energy solutions, aluminum extrusion stands out as a sustainable choice across various industries. As we continue to seek environmentally responsible materials in manufacturing and construction, aluminum extrusion will play a pivotal role in promoting sustainability and reducing our ecological footprint. By addressing challenges related to production intensity and market volatility while emphasizing its advantages, industries can leverage aluminum extrusion as part of a broader strategy toward sustainability.

FAQ

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process that shapes aluminum by forcing it through a die to create specific profiles used in various applications.

2. Why is aluminum considered environmentally friendly?

Aluminum is environmentally friendly due to its infinite recyclability, low energy consumption during production and recycling processes, and its durability which reduces waste over time.

3. How does recycling aluminum benefit the environment?

Recycling aluminum saves approximately 95% of the energy required for primary production, significantly reduces greenhouse gas emissions, and conserves natural resources by decreasing the need for mining new materials.

4. What applications benefit from using aluminum extrusions?

Aluminum extrusions are widely used in construction (windows, doors), automotive (lightweight components), aerospace (aircraft parts), and renewable energy (solar panel frames).

5. How does using aluminum reduce carbon emissions?

Using lightweight aluminum components in vehicles improves fuel efficiency, which leads to lower carbon emissions during operation compared to heavier materials like steel.

Citations:

[1] https://kimsen.vn/the-benefits-of-aluminum-extrusion-for-sustainable-manufacturing-ne142.html

[2] https://www.nicerapid.com/project/the-impact-of-aluminum-extrusion-process-on-the-environment/

[3] https://kmcaluminium.com/embarking-on-a-greener-future-the-environmental-benefits-of-aluminium-production-and-recycling/

[4] https://www.alamy.com/stock-photo/aluminum-extrusion.html

[5] https://www.youtube.com/watch?v=iiGlq7408ME

[6] https://customaluminumextrusion.com/blog/benefits-of-aluminum-extrusions-for-the-environment

[7] https://aec.org/sites/default/files/styles/site_max/public/2022-05/aluminum_production_with_extrusion_infographic_sustainability_AEC.png?itok=3x1qUrQV&sa=X&ved=2ahUKEwi00fnEyq6KAxVZvokEHYW5A44Q_B16BAgCEAI

[8] https://www.freepik.com/free-photos-vectors/aluminum-extrusion

[9] https://www.youtube.com/watch?v=vHkwq_2yY9E

[10] https://www.retop-industry.com/news/aluminum-profile.html

[11] https://taberextrusions.com/environmental-advantages-of-aluminum-extrusions/