Content Menu

● Introduction

● Understanding 3030 Aluminum Profiles

● Benefits of Using 3030 Aluminum Profiles

>> Versatility

>> Strength and Durability

>> Lightweight

● Common Applications of 3030 Aluminum Profiles

>> Robotics

>> Furniture Design

>> Industrial Machinery

>> Automation Systems

>> Architectural Applications

>> DIY Projects

● How to Select the Right 3030 Aluminum Profile for Your Project

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using 3030 aluminum extrusions?

>> 2. Can 3030 aluminum profiles be customized for specific projects?

>> 3. What industries commonly use 3030 aluminum extrusions?

>> 4. How do I determine the right 3030 aluminum profile for my project?

>> 5. Are 3030 aluminum extrusions suitable for outdoor use?

Introduction

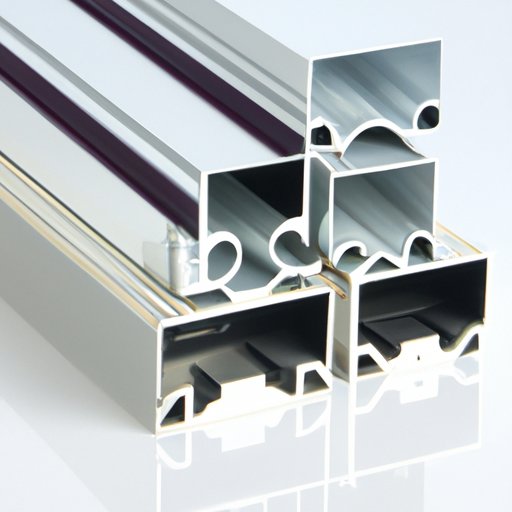

Aluminum extrusions have become a cornerstone in modern manufacturing and construction due to their versatility, strength, and lightweight properties. Among the various types of aluminum extrusions, the 3030 aluminum extrusion stands out for its unique dimensions and applications. This article delves into the common applications of 3030 aluminum extrusions, exploring their benefits, versatility, and the industries that utilize them.

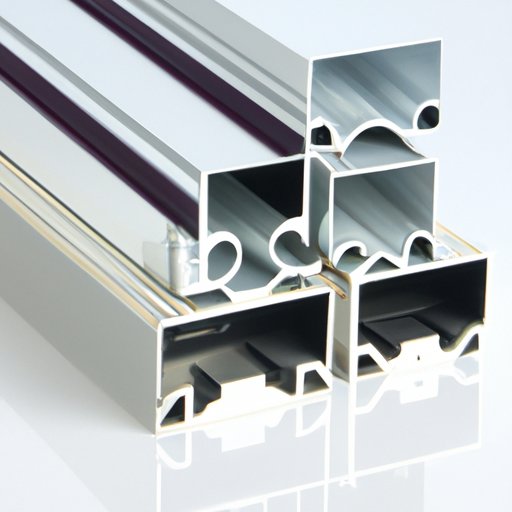

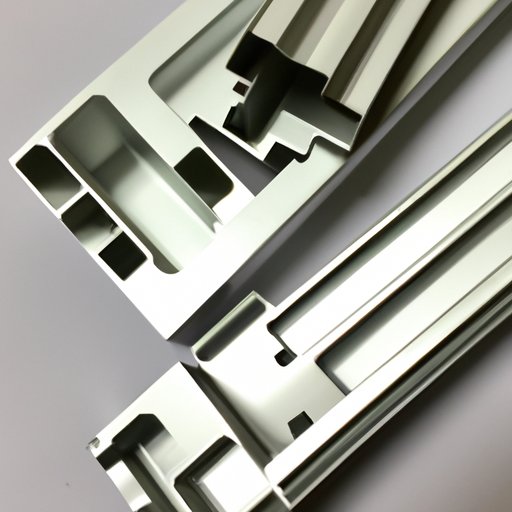

Understanding 3030 Aluminum Profiles

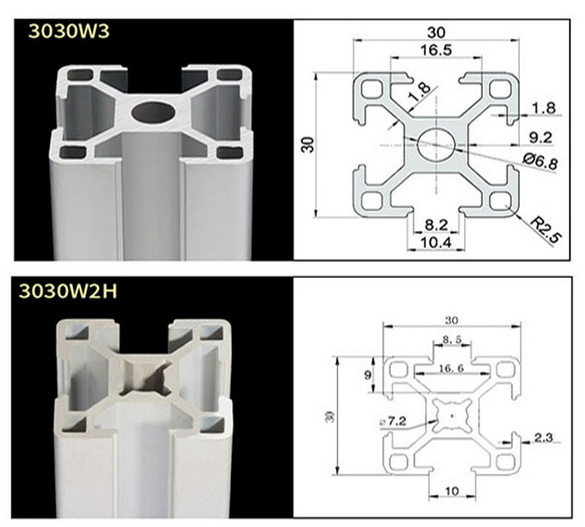

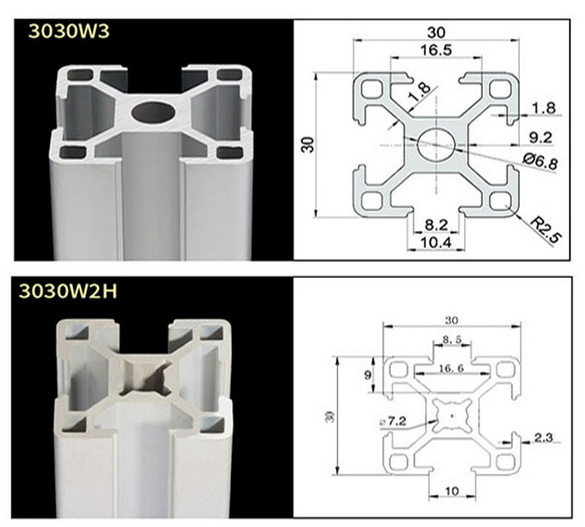

The 3030 aluminum profile is characterized by its dimensions of 30mm x 30mm, making it a popular choice for a variety of applications. Its square shape allows for easy assembly and integration into different structures. The profile is typically made from high-strength aluminum alloy, which provides excellent durability and resistance to corrosion.

One of the key features of the 3030 aluminum extrusion is its compatibility with T-slot framing systems. This design allows for the easy attachment of various components, making it ideal for modular construction. The 3030 profile can be used in conjunction with other aluminum profiles, such as 2020 and 4040, to create complex structures tailored to specific needs.

Benefits of Using 3030 Aluminum Profiles

Versatility

One of the most significant advantages of 3030 aluminum profiles is their versatility. They can be used in a wide range of applications, from industrial machinery to furniture design. The ability to customize the profiles further enhances their adaptability, allowing engineers and designers to create solutions that meet specific project requirements.

Strength and Durability

3030 aluminum extrusions are known for their strength and durability. The aluminum alloy used in these profiles provides a high strength-to-weight ratio, making them suitable for applications that require robust structural support without adding excessive weight. This characteristic is particularly beneficial in industries such as aerospace and automotive, where weight reduction is crucial for efficiency.

Lightweight

The lightweight nature of 3030 aluminum profiles makes them easy to handle and transport. This property is especially advantageous in construction and manufacturing, where reducing the weight of materials can lead to lower shipping costs and easier assembly. The lightweight design does not compromise strength, making 3030 aluminum extrusions an ideal choice for various applications.

Common Applications of 3030 Aluminum Profiles

Robotics

One of the most prominent applications of 3030 aluminum extrusions is in the field of robotics. The profiles are used to construct robot frames, providing a lightweight yet sturdy structure that can support various components such as motors, sensors, and control systems. The modular nature of the 3030 profile allows for easy adjustments and modifications, making it a favorite among robotics engineers.

Furniture Design

3030 aluminum profiles are increasingly being used in furniture design, particularly in modern and industrial-style furniture. The sleek appearance of aluminum combined with its strength makes it an attractive option for creating tables, chairs, and shelving units. Designers appreciate the ability to create custom pieces that are both functional and aesthetically pleasing.

Industrial Machinery

In industrial settings, 3030 aluminum extrusions are often used to build frames and supports for machinery. Their strength and durability make them suitable for heavy-duty applications, while their lightweight nature allows for easier installation and maintenance. The profiles can be used to create protective enclosures, conveyor systems, and workstations, enhancing the efficiency of manufacturing processes.

Automation Systems

Automation systems benefit significantly from the use of 3030 aluminum profiles. These profiles can be used to construct the framework for automated assembly lines, robotic arms, and conveyor systems. The ability to easily integrate sensors and other components into the T-slot design allows for efficient automation solutions that can be tailored to specific production needs.

Architectural Applications

In architecture, 3030 aluminum extrusions are used for various structural and decorative elements. They can be found in window frames, curtain walls, and even as part of the building's structural framework. The corrosion resistance of aluminum ensures that these components maintain their appearance and structural integrity over time, making them a reliable choice for architects and builders.

DIY Projects

The DIY community has embraced 3030 aluminum extrusions for various projects. Hobbyists and makers use these profiles to create everything from custom shelving units to intricate models. The ease of assembly and customization makes 3030 aluminum profiles a popular choice for those looking to build unique projects without the need for specialized tools or skills.

How to Select the Right 3030 Aluminum Profile for Your Project

When selecting a 3030 aluminum profile for a project, several factors should be considered:

- Load Requirements: Determine the weight and load that the profile will need to support. This will help in selecting the appropriate thickness and alloy.

- Environmental Conditions: Consider the environment in which the profile will be used. If it will be exposed to moisture or chemicals, ensure that the aluminum alloy is suitable for such conditions.

- Customization Needs: Assess whether the project requires custom lengths, cuts, or additional features. Many suppliers offer customization options for 3030 aluminum profiles.

- Assembly Requirements: Evaluate how the profiles will be assembled. The T-slot design allows for easy integration with other components, so consider the overall design of the project.

Conclusion

3030 aluminum extrusions are a versatile and valuable material in various industries, from robotics to architecture. Their unique properties, including strength, lightweight design, and adaptability, make them suitable for a wide range of applications. As technology continues to advance, the use of 3030 aluminum profiles is likely to expand, offering even more innovative solutions for engineers, designers, and DIY enthusiasts alike.

Frequently Asked Questions

1. What are the main advantages of using 3030 aluminum extrusions?

3030 aluminum extrusions offer several advantages, including versatility, strength, lightweight properties, and ease of assembly. These features make them suitable for a wide range of applications across various industries.

2. Can 3030 aluminum profiles be customized for specific projects?

Yes, 3030 aluminum profiles can be customized in terms of length, cuts, and additional features. Many suppliers offer customization options to meet specific project requirements.

3. What industries commonly use 3030 aluminum extrusions?

3030 aluminum extrusions are commonly used in industries such as robotics, furniture design, industrial machinery, automation systems, and architecture.

4. How do I determine the right 3030 aluminum profile for my project?

To determine the right 3030 aluminum profile, consider factors such as load requirements, environmental conditions, customization needs, and assembly requirements.

5. Are 3030 aluminum extrusions suitable for outdoor use?

Yes, 3030 aluminum extrusions are suitable for outdoor use due to their corrosion resistance. However, it is essential to choose the appropriate aluminum alloy based on the specific environmental conditions.