Content Menu

● Understanding Aluminum Extrusion

● Benefits of 1/4 Round Aluminum Extrusion

● Common Applications of 1/4 Round Aluminum Extrusion

>> Architectural Applications

>> Furniture Manufacturing

>> Automotive Industry

>> Electrical Enclosures

>> Signage and Displays

>> Railings and Guardrails

>> HVAC Systems

>> Custom Applications

● Conclusion

● Frequently Asked Questions

>> 1. What is the difference between aluminum extrusion and aluminum casting?

>> 2. Can 1/4 round aluminum extrusion be painted?

>> 3. Is aluminum extrusion environmentally friendly?

>> 4. What are the common finishes for aluminum extrusions?

>> 5. How do I choose the right aluminum extrusion for my project?

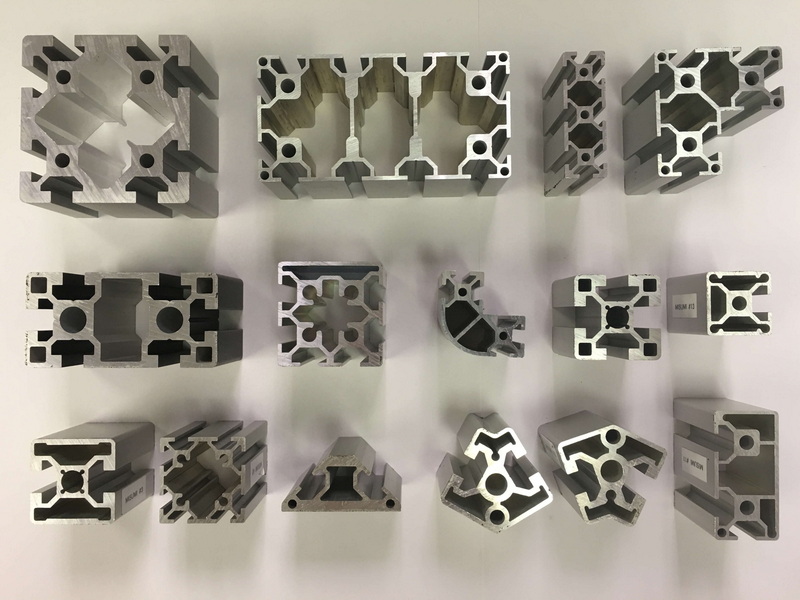

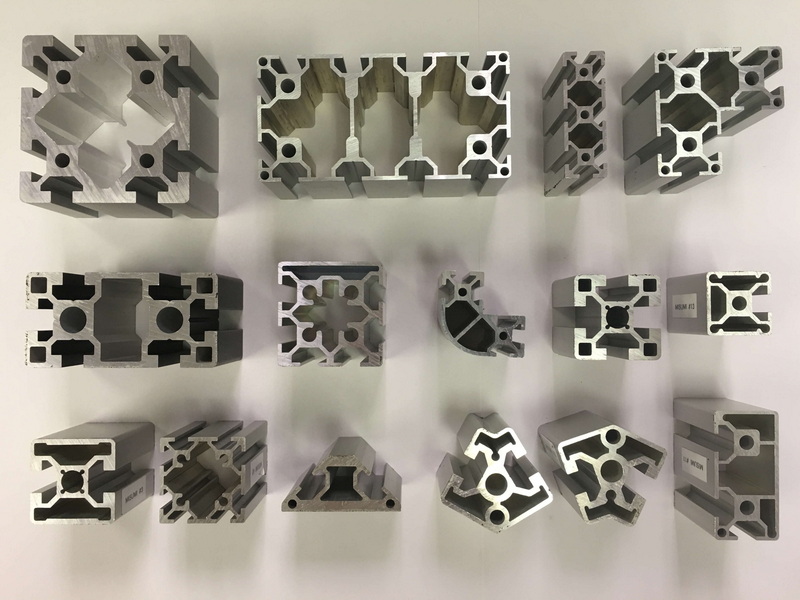

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. One of the popular profiles is the 1/4 round aluminum extrusion, which features a rounded edge on one side and a flat edge on the other. This unique shape makes it versatile for various applications across different industries. In this article, we will explore the common applications of 1/4 round aluminum extrusion, its benefits, and why it is a preferred choice for many projects.

Understanding Aluminum Extrusion

Before diving into the applications, it's essential to understand what aluminum extrusion is. The process involves forcing heated aluminum through a die to create a specific shape. The resulting extruded aluminum can be cut to length and finished in various ways, including anodizing, painting, or powder coating. The 1/4 round profile is particularly popular due to its aesthetic appeal and functional properties.

Benefits of 1/4 Round Aluminum Extrusion

1. Lightweight: Aluminum is significantly lighter than other metals, making it easier to handle and transport.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps resist corrosion, making it suitable for outdoor applications.

3. Versatility: The 1/4 round shape can be used in various applications, from construction to automotive parts.

4. Aesthetic Appeal: The rounded edge provides a sleek and modern look, enhancing the overall design of products.

5. Ease of Fabrication: Aluminum can be easily cut, drilled, and machined, allowing for customization in projects.

Common Applications of 1/4 Round Aluminum Extrusion

Architectural Applications

One of the most common uses of 1/4 round aluminum extrusion is in architectural applications. It is often used as trim or molding in buildings, providing a clean and finished look to edges and corners. The rounded edge helps to soften the appearance of sharp corners, making it a popular choice for both interior and exterior designs. Architects and designers appreciate the ability to incorporate aluminum extrusions into their projects, as they can be easily integrated into various styles, from modern to traditional.

Furniture Manufacturing

In the furniture industry, 1/4 round aluminum extrusion is used in various products, including tables, chairs, and shelving units. The lightweight nature of aluminum allows for easy mobility, while the strength of the material ensures durability. Additionally, the aesthetic appeal of the rounded edges adds a modern touch to furniture designs. Manufacturers often choose aluminum extrusions for their ability to create sleek, minimalist designs that are both functional and visually appealing.

Automotive Industry

The automotive industry utilizes 1/4 round aluminum extrusion for various components, including trim pieces, structural supports, and decorative elements. The lightweight properties of aluminum contribute to fuel efficiency, making it an ideal choice for modern vehicles. Furthermore, the corrosion resistance of aluminum ensures longevity in harsh environments. As the automotive industry continues to focus on reducing weight to improve fuel efficiency, the demand for aluminum extrusions is expected to grow.

Electrical Enclosures

1/4 round aluminum extrusion is commonly used in the manufacturing of electrical enclosures. The rounded edges provide a safe and secure fit for electrical components, while the aluminum material offers excellent heat dissipation. This application is crucial in ensuring the safety and reliability of electrical systems. Manufacturers often design custom enclosures using aluminum extrusions to meet specific requirements, ensuring that the final product is both functional and aesthetically pleasing.

Signage and Displays

In the signage industry, 1/4 round aluminum extrusion is often used to create frames for signs and displays. The lightweight yet sturdy nature of aluminum allows for easy installation and maintenance. The rounded edges provide a polished look, enhancing the overall appearance of the signage. Businesses frequently use aluminum extrusions for outdoor signs, as they can withstand various weather conditions while maintaining their appearance.

Railings and Guardrails

1/4 round aluminum extrusion is also used in the construction of railings and guardrails. The rounded edge provides a comfortable grip, making it ideal for handrails in staircases and balconies. Additionally, the corrosion resistance of aluminum ensures that these structures remain safe and visually appealing over time. Architects and builders appreciate the versatility of aluminum railings, as they can be designed to fit various architectural styles and requirements.

HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, 1/4 round aluminum extrusion is used for ductwork and framing. The lightweight nature of aluminum makes it easy to install, while its durability ensures that it can withstand the rigors of HVAC applications. The rounded edges help to improve airflow and reduce turbulence within the system. As energy efficiency becomes increasingly important, the use of aluminum in HVAC systems is expected to rise.

Custom Applications

Many industries utilize 1/4 round aluminum extrusion for custom applications. This includes everything from specialized machinery to unique architectural features. The ability to customize the length and finish of the extrusion allows for endless possibilities in design and functionality. Engineers and designers often collaborate to create bespoke solutions that meet specific project requirements, leveraging the versatility of aluminum extrusions.

Conclusion

The 1/4 round aluminum extrusion is a versatile and widely used profile in various industries. Its lightweight, corrosion-resistant properties, and aesthetic appeal make it an ideal choice for applications ranging from architecture to automotive manufacturing. As industries continue to innovate, the demand for aluminum extrusions, particularly the 1/4 round profile, is expected to grow. The ability to customize these extrusions further enhances their appeal, allowing for tailored solutions that meet the unique needs of different projects.

Frequently Asked Questions

1. What is the difference between aluminum extrusion and aluminum casting?

Aluminum extrusion involves shaping aluminum by forcing it through a die, while aluminum casting involves pouring molten aluminum into a mold to create a specific shape. Extrusion is typically used for creating long, continuous shapes, while casting is better suited for complex, detailed parts.

2. Can 1/4 round aluminum extrusion be painted?

Yes, 1/4 round aluminum extrusion can be painted or anodized to achieve different colors and finishes. Anodizing not only enhances the appearance but also increases corrosion resistance, making it suitable for outdoor applications.

3. Is aluminum extrusion environmentally friendly?

Yes, aluminum is recyclable, and the extrusion process generates less waste compared to other manufacturing methods. Many manufacturers are adopting sustainable practices, further reducing the environmental impact of aluminum production.

4. What are the common finishes for aluminum extrusions?

Common finishes include anodizing, powder coating, and painting, which enhance the appearance and durability of the aluminum. Each finish offers different benefits, such as improved corrosion resistance or aesthetic appeal.

5. How do I choose the right aluminum extrusion for my project?

Consider factors such as the intended application, load requirements, environmental conditions, and aesthetic preferences when selecting an aluminum extrusion. Consulting with a manufacturer or supplier can also provide valuable insights into the best options for your specific needs.