Content Menu

● Understanding Aluminum Extrusion

>> Benefits of Using Aluminum Extrusion

● Best Uses for 8 Ft Aluminum Extrusion in DIY Projects

>> Building Frames for Furniture

>> DIY Workbenches

>> Greenhouses and Garden Structures

>> Custom Racks and Shelving

>> Robotics and Automation Projects

>> Display Stands and Exhibits

>> Home Automation and Smart Home Projects

>> Art and Sculpture

● Tips for Working with 8 Ft Aluminum Extrusion

● Frequently Asked Questions

>> 1. What tools do I need to work with aluminum extrusion?

>> 2. Can I paint aluminum extrusion?

>> 3. Is aluminum extrusion suitable for outdoor use?

>> 4. How do I join two pieces of aluminum extrusion?

>> 5. Can I cut aluminum extrusion at home?

Aluminum extrusion is a versatile material that has gained immense popularity in various DIY projects. Among the different sizes available, the 8 ft aluminum extrusion stands out due to its length and adaptability. This article explores the best uses for 8 ft aluminum extrusion in DIY projects, providing insights into its benefits, applications, and tips for effective use.

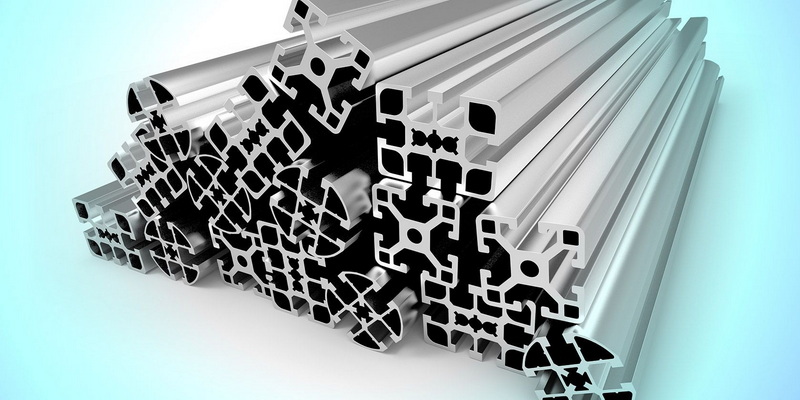

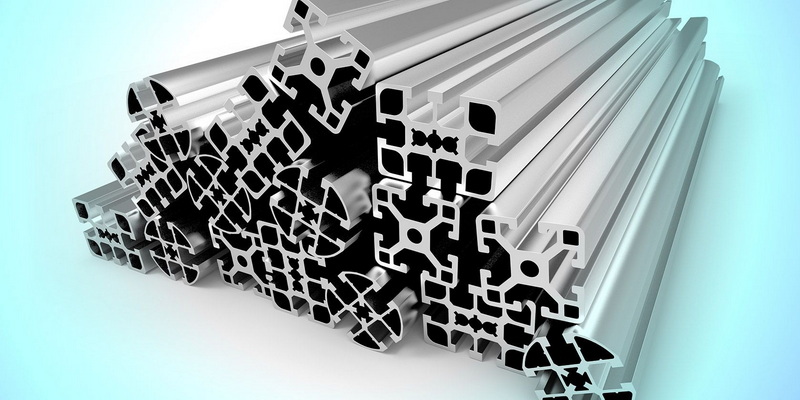

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy into a desired cross-sectional profile. The process begins with heating aluminum billets until they become malleable, followed by forcing them through a die to create long lengths of material with consistent cross-sections. This method allows for the production of complex shapes that are lightweight yet strong, making aluminum extrusion ideal for a wide range of applications.

Benefits of Using Aluminum Extrusion

1. Lightweight and Durable: Aluminum is significantly lighter than steel, making it easier to handle and transport. Despite its lightness, it offers excellent strength-to-weight ratios, making it suitable for structural applications.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer that prevents corrosion, making it ideal for outdoor projects and environments where moisture is a concern.

3. Versatility: The ability to create custom shapes and sizes means that aluminum extrusion can be tailored to meet specific project requirements, whether for furniture, frames, or other structures.

4. Ease of Assembly: Many aluminum extrusions come with T-slots or other fastening features that simplify assembly, allowing for quick and efficient construction.

5. Recyclability: Aluminum is 100% recyclable without loss of quality, making it an environmentally friendly choice for DIY projects.

Best Uses for 8 Ft Aluminum Extrusion in DIY Projects

Building Frames for Furniture

One of the most popular uses for 8 ft aluminum extrusion is in the construction of furniture frames. The lightweight nature of aluminum makes it easy to create sturdy yet portable furniture. For instance, you can build a custom table or shelving unit using aluminum extrusions as the main structural components. The T-slot design allows for easy adjustments and modifications, enabling you to create a piece that fits your specific needs.

DIY Workbenches

Creating a workbench is another excellent application for 8 ft aluminum extrusion. The strength and stability of aluminum make it perfect for supporting heavy tools and materials. You can design a workbench that suits your workspace, incorporating features like adjustable height or integrated storage solutions. The modular nature of aluminum extrusions allows for easy customization, ensuring your workbench meets your specific requirements.

Greenhouses and Garden Structures

Aluminum extrusions are also ideal for building greenhouses and other garden structures. Their resistance to corrosion makes them suitable for outdoor use, and their lightweight nature allows for easy assembly. You can create a custom greenhouse frame that fits your garden space, ensuring optimal sunlight exposure for your plants. Additionally, aluminum can be combined with polycarbonate panels to create a durable and efficient greenhouse.

Custom Racks and Shelving

Another practical use for 8 ft aluminum extrusion is in the creation of custom racks and shelving units. Whether for a garage, workshop, or home, aluminum extrusions can be configured to create strong and lightweight storage solutions. The ability to adjust the height and spacing of shelves makes it easy to accommodate various items, from tools to books.

Robotics and Automation Projects

For hobbyists and engineers, 8 ft aluminum extrusion is a popular choice for building frames for robotics and automation projects. The precision and strength of aluminum allow for the construction of complex structures that can support motors, sensors, and other components. The modular design enables easy modifications and upgrades, making it a favorite among DIY robotics enthusiasts.

Display Stands and Exhibits

If you're involved in trade shows or exhibitions, aluminum extrusions can be used to create lightweight and portable display stands. The ability to customize the height and design of the stand allows for unique presentations that can attract attention. Additionally, the ease of assembly and disassembly makes aluminum extrusions a practical choice for traveling exhibits.

Home Automation and Smart Home Projects

With the rise of smart home technology, aluminum extrusions can be utilized to create frames for home automation devices. Whether it's a custom mount for a smart speaker or a housing for sensors, aluminum provides a sleek and modern look while ensuring durability. The modular nature of aluminum extrusions allows for easy integration of various components.

Art and Sculpture

Artists and sculptors are increasingly using aluminum extrusions to create unique pieces of art. The versatility of aluminum allows for intricate designs and structures that can be both functional and aesthetic. Whether creating a large outdoor sculpture or a small indoor piece, aluminum extrusions provide the strength and flexibility needed for artistic expression.

Tips for Working with 8 Ft Aluminum Extrusion

1. Plan Your Design: Before starting your project, sketch out your design and plan the dimensions. This will help you determine how much aluminum extrusion you need and how to cut it effectively.

2. Use the Right Tools: Cutting aluminum extrusion requires specific tools. A miter saw with a fine-toothed blade or a band saw is ideal for making clean cuts. Ensure you have clamps to hold the material securely while cutting.

3. Consider Fastening Options: Aluminum extrusions often come with T-slots that allow for easy fastening. Use appropriate connectors and fasteners to ensure a secure assembly. Consider using corner brackets for added stability.

4. Finish the Edges: After cutting, smooth the edges of the aluminum extrusion to prevent sharp edges that could cause injury. You can use a file or sandpaper for this purpose.

5. Experiment with Designs: Don't hesitate to experiment with different configurations and designs. The modular nature of aluminum extrusions allows for easy adjustments, so you can modify your project as needed.

Frequently Asked Questions

1. What tools do I need to work with aluminum extrusion?

You will need a miter saw or band saw for cutting, clamps for securing the material, and appropriate fasteners for assembly.

2. Can I paint aluminum extrusion?

Yes, aluminum can be painted. Ensure the surface is clean and consider using a primer designed for metal surfaces for better adhesion.

3. Is aluminum extrusion suitable for outdoor use?

Yes, aluminum is naturally resistant to corrosion, making it an excellent choice for outdoor projects.

4. How do I join two pieces of aluminum extrusion?

You can use T-slot connectors, corner brackets, or other fastening methods designed for aluminum extrusions to join pieces securely.

5. Can I cut aluminum extrusion at home?

Yes, you can cut aluminum extrusion at home using the right tools, such as a miter saw or band saw, ensuring you follow safety precautions.