Content Menu

● Introduction

● Understanding Aluminum Extrusions

● Essential Tools for Cutting Aluminum Extrusions

● Safety Precautions

● Cutting Techniques

>> Step-by-Step Guide on How to Cut Aluminum Extrusions Safely

>> Tips for Achieving Clean and Precise Cuts

● Post-Cutting Safety and Maintenance

● Conclusion

● Related Questions

>> 1. What tools are best for cutting aluminum extrusions?

>> 2. How can I ensure safety while cutting aluminum?

>> 3. What are common mistakes to avoid when cutting aluminum extrusions?

>> 4. How do I achieve precision cuts in aluminum extrusions?

>> 5. Can I cut aluminum extrusions with a regular saw?

Introduction

Cutting aluminum extrusions is a common task in various industries, including construction, manufacturing, and DIY projects. Aluminum extrusions are lightweight, durable, and versatile, making them ideal for a wide range of applications. However, cutting them requires specific techniques and tools to ensure safety and precision. In this article, we will explore the best techniques for cutting aluminum extrusions, focusing on safety precautions, essential tools, and effective cutting methods.

Understanding Aluminum Extrusions

Aluminum extrusions are created by forcing aluminum alloy through a die to produce a specific shape. This process allows for the creation of complex profiles that can be used in various applications, such as window frames, structural components, and decorative elements. The lightweight nature of aluminum, combined with its resistance to corrosion, makes it a popular choice for many projects.

When cutting aluminum extrusions, it is essential to understand the properties of the material. Aluminum is softer than steel, which means it can be cut more easily, but it also means that it can be prone to bending or warping if not handled correctly. Therefore, using the right techniques and tools is crucial for achieving clean and precise cuts.

Essential Tools for Cutting Aluminum Extrusions

To cut aluminum extrusions effectively, you will need the right tools. Here are some of the most commonly used tools for this task:

- Miter Saw: A miter saw is one of the best tools for cutting aluminum extrusions. It allows for precise angled cuts and can handle various sizes of extrusions. When using a miter saw, it is essential to equip it with a blade specifically designed for cutting non-ferrous metals.

- Circular Saw: A circular saw is another versatile tool that can be used for cutting aluminum extrusions. It is particularly useful for making long, straight cuts. Like the miter saw, it is crucial to use a blade designed for cutting aluminum to prevent damage to the material and ensure a clean cut.

- Hacksaw: For smaller projects or when precision is not as critical, a hacksaw can be used to cut aluminum extrusions. This manual tool is less efficient than power saws but can be effective for quick cuts.

- Band Saw: A band saw is ideal for cutting thicker aluminum extrusions. It provides a smooth cut and is suitable for both straight and curved cuts. When using a band saw, ensure that the blade is appropriate for cutting aluminum.

- Table Saw: A table saw can also be used for cutting aluminum extrusions, especially for larger pieces. It allows for precise cuts and can handle various thicknesses of aluminum. Again, using the right blade is essential for achieving the best results.

Safety Precautions

Safety should always be a top priority when cutting aluminum extrusions. Here are some essential safety precautions to follow:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety goggles, gloves, and hearing protection. This equipment will help protect you from flying debris and noise from the cutting tools.

- Workspace Setup: Ensure that your workspace is clean and organized. Remove any unnecessary items that could pose a tripping hazard. Make sure that your cutting area is well-lit to improve visibility.

- Securing the Material: Before cutting, secure the aluminum extrusion in place using clamps or a vise. This will prevent the material from moving during the cutting process, reducing the risk of injury and ensuring a more accurate cut.

- Using the Right Blade: Always use a blade specifically designed for cutting aluminum. Using the wrong blade can lead to poor cuts and increase the risk of accidents.

- Following Manufacturer Instructions: Always read and follow the manufacturer's instructions for your cutting tools. This will help you understand the proper usage and maintenance of the equipment.

Cutting Techniques

Now that we have covered the essential tools and safety precautions, let's explore the best techniques for cutting aluminum extrusions.

Step-by-Step Guide on How to Cut Aluminum Extrusions Safely

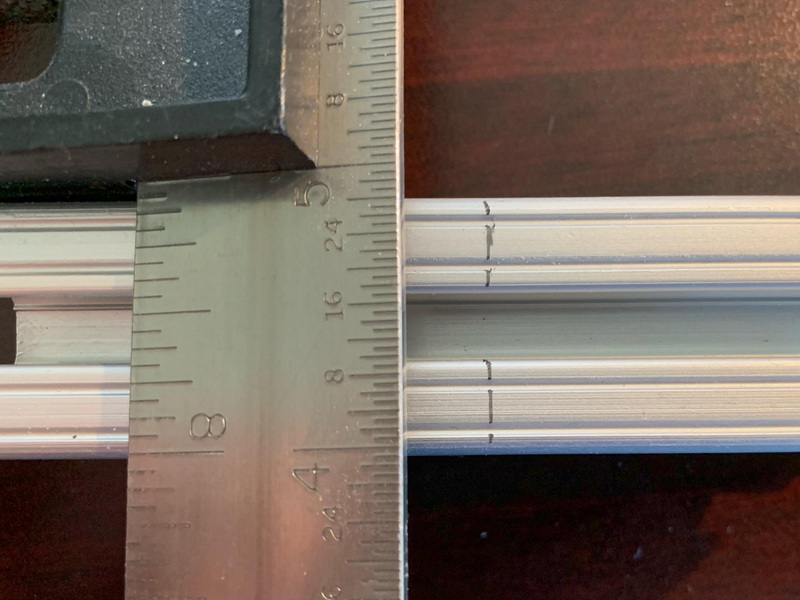

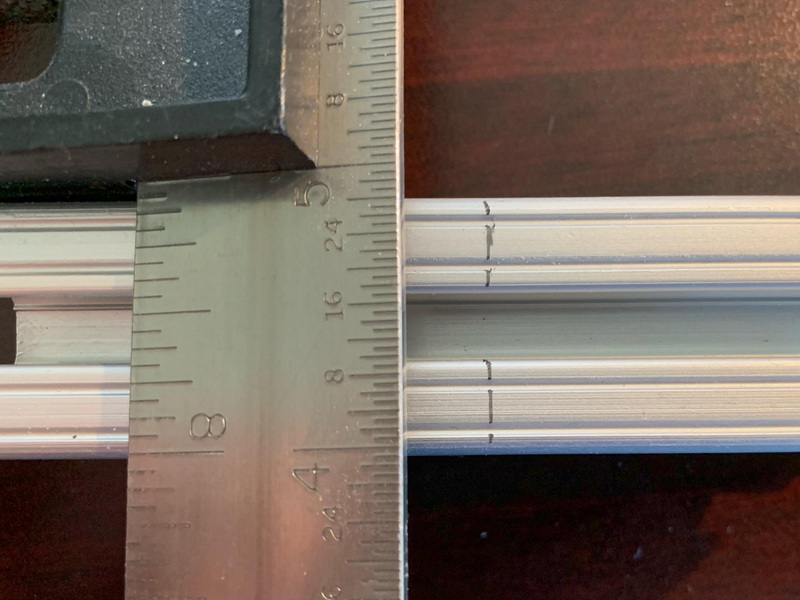

1. Measure and Mark: Start by measuring the length you need to cut from the aluminum extrusion. Use a measuring tape and a marker to make a clear line where you will cut. Double-check your measurements to ensure accuracy.

2. Secure the Material: Place the aluminum extrusion on a stable surface and secure it using clamps or a vise. Make sure it is held firmly in place to prevent any movement during the cutting process.

3. Select the Right Tool: Choose the appropriate cutting tool based on the size and thickness of the aluminum extrusion. For most projects, a miter saw or circular saw will be the best choice.

4. Set Up the Tool: If using a miter saw, adjust the angle of the blade if you need to make angled cuts. Ensure that the blade is sharp and suitable for cutting aluminum.

5. Cutting Process: Align the blade with the marked line on the aluminum extrusion. Turn on the saw and allow it to reach full speed before making contact with the material. Use steady, even pressure to guide the saw through the extrusion. Avoid forcing the saw, as this can lead to uneven cuts or damage to the material.

6. Finishing the Cut: Once the cut is complete, turn off the saw and allow the blade to come to a complete stop before removing the aluminum extrusion. Inspect the cut for any rough edges.

7. Deburring: After cutting, it is essential to deburr the edges of the aluminum extrusion. Use a file or deburring tool to smooth out any sharp edges, which will help prevent injuries and improve the appearance of the cut.

Tips for Achieving Clean and Precise Cuts

- Use a Cutting Fluid: Applying a cutting fluid can help reduce friction and heat during the cutting process, resulting in cleaner cuts and prolonging the life of the blade.

- Maintain a Steady Hand: Keep a steady hand while cutting to ensure that the blade follows the marked line accurately. Practice on scrap pieces if you are new to cutting aluminum.

- Check Blade Alignment: Regularly check the alignment of your saw blade to ensure it is perpendicular to the base. Misalignment can lead to uneven cuts.

- Avoid Overheating: If you notice the blade getting too hot, take breaks to allow it to cool down. Overheating can damage both the blade and the aluminum extrusion.

Post-Cutting Safety and Maintenance

After cutting aluminum extrusions, it is essential to follow proper safety and maintenance procedures:

- Clean Up the Workspace: Remove any debris, shavings, or scraps from the cutting area. This will help prevent accidents and keep your workspace organized.

- Inspect Tools: After use, inspect your cutting tools for any signs of wear or damage. Replace blades as needed to ensure optimal performance.

- Store Materials Safely: Store any leftover aluminum extrusions in a safe and organized manner to prevent accidents. Use racks or bins to keep them secure.

- Regular Maintenance: Perform regular maintenance on your cutting tools, including cleaning and lubricating moving parts. This will help extend the life of your equipment and ensure safe operation.

Conclusion

Cutting aluminum extrusions can be a straightforward task when you have the right tools, techniques, and safety precautions in place. By understanding the properties of aluminum, using the appropriate cutting tools, and following safety guidelines, you can achieve clean and precise cuts for your projects. Whether you are a professional or a DIY enthusiast, mastering the art of cutting aluminum extrusions will enhance your skills and improve the quality of your work.

Related Questions

1. What tools are best for cutting aluminum extrusions?

The best tools for cutting aluminum extrusions include miter saws, circular saws, band saws, and hacksaws. Each tool has its advantages depending on the size and thickness of the extrusion.

2. How can I ensure safety while cutting aluminum?

To ensure safety, always wear personal protective equipment, secure the material properly, use the right tools and blades, and maintain a clean workspace.

3. What are common mistakes to avoid when cutting aluminum extrusions?

Common mistakes include using the wrong blade, not securing the material, rushing the cutting process, and neglecting safety precautions.

4. How do I achieve precision cuts in aluminum extrusions?

To achieve precision cuts, measure carefully, use sharp blades, maintain a steady hand, and secure the material firmly before cutting.

5. Can I cut aluminum extrusions with a regular saw?

While you can use a regular saw, it is recommended to use tools specifically designed for cutting aluminum, such as miter saws or circular saws, to achieve better results and safety.