Content Menu

● Understanding Aluminum Extrusions

● Preparing for Installation

● Step-by-Step Installation Process

>> 1. Measure and Cut the Extrusions

>> 2. Prepare the Work Area

>> 3. Assemble the Frame

>> 4. Secure the Joints

>> 5. Check for Level and Square

>> 6. Add Additional Support

>> 7. Finishing Touches

● Common Mistakes to Avoid

● Maintenance Tips

● Conclusion

● Related Questions

>> 1. What are the typical load capacities for 15x15 aluminum extrusions?

>> 2. How do different types of fasteners affect the structural integrity of the assembly?

>> 3. What are some common applications for 15x15 aluminum extrusions in DIY projects?

>> 4. Can I paint or anodize aluminum extrusions?

>> 5. What tools are essential for working with aluminum extrusions?

Aluminum extrusions are widely used in various industries due to their lightweight, strength, and versatility. The 15x15 aluminum extrusion is particularly popular for DIY projects, structural frameworks, and custom builds. This article will explore best practices for installing 15x15 aluminum extrusions, ensuring a successful and durable assembly.

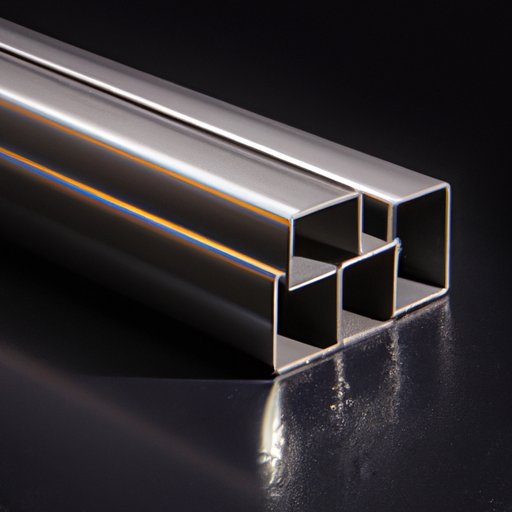

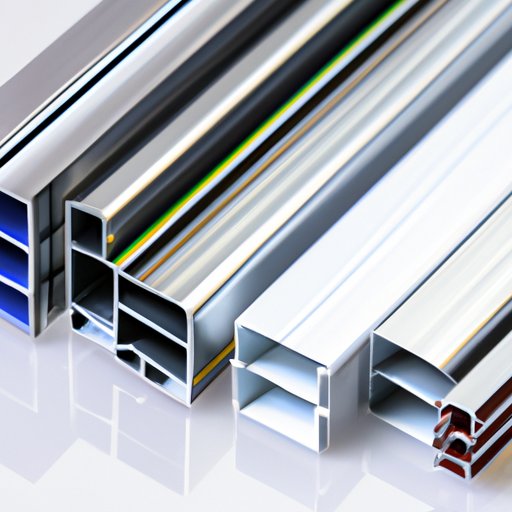

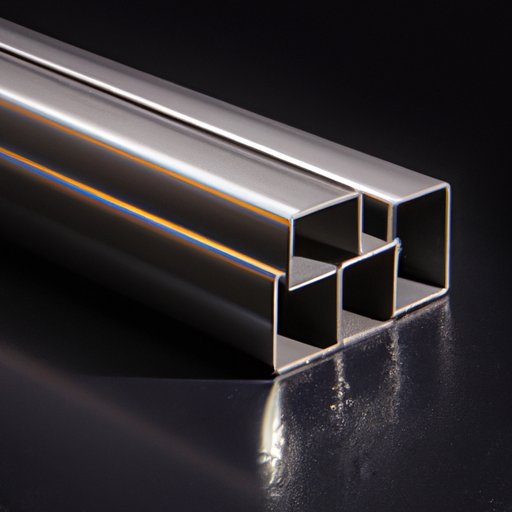

Understanding Aluminum Extrusions

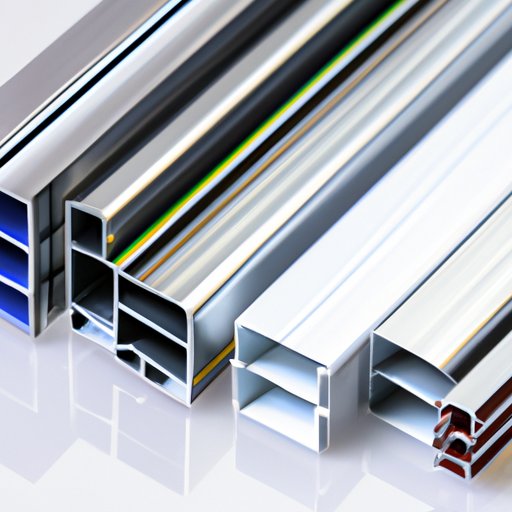

Aluminum extrusions are created by forcing aluminum through a shaped die, resulting in a specific cross-sectional profile. The 15x15 extrusion refers to a profile that is 15mm by 15mm in size. This size is ideal for a variety of applications, including frames for machines, furniture, and even architectural elements.

Preparing for Installation

Before beginning the installation process, it is essential to gather all necessary tools and materials. Here's a checklist of what you will need:

- Tools:

- Miter saw or hacksaw

- Drill and drill bits

- T-slot nuts

- Bolts and screws

- Measuring tape

- Square

- Level

- Safety goggles

- Materials:

- 15x15 aluminum extrusions

- End caps (if required)

- Fasteners (screws, bolts, etc.)

- Optional: brackets for additional support

Step-by-Step Installation Process

1. Measure and Cut the Extrusions

Accurate measurements are crucial for a successful installation. Use a measuring tape to determine the lengths needed for your project. Mark the cut lines clearly on the aluminum extrusion. When cutting, ensure that the saw blade is appropriate for aluminum to achieve a clean cut.

2. Prepare the Work Area

Set up a clean and organized workspace. Ensure that you have enough room to maneuver the extrusions and tools. A flat surface will help in aligning the pieces accurately.

3. Assemble the Frame

Start by laying out the extrusions in the desired configuration. Use a square to ensure that the corners are at right angles. This step is vital for maintaining the structural integrity of the assembly.

4. Secure the Joints

Using T-slot nuts and bolts, secure the joints of the extrusions. Insert the T-slot nuts into the grooves of the aluminum profile before tightening the bolts. This method allows for easy adjustments and disassembly if needed.

5. Check for Level and Square

After securing the joints, use a level to check that the frame is even. Adjust as necessary to ensure that everything is square. This step is crucial for the stability of the final structure.

6. Add Additional Support

Depending on the application, you may need to add brackets or additional extrusions for support. This is especially important for larger structures or those that will bear significant loads.

7. Finishing Touches

Once the frame is assembled, consider adding end caps to the exposed ends of the extrusions for a polished look. This step also helps to prevent dirt and debris from entering the profile.

Common Mistakes to Avoid

1. Inaccurate Measurements: Always double-check your measurements before cutting. A small error can lead to significant issues in assembly.

2. Neglecting Safety: Always wear safety goggles when cutting or drilling aluminum to protect your eyes from metal shavings.

3. Over-tightening Fasteners: While it's important to secure the joints, over-tightening can strip the threads or damage the extrusion.

4. Ignoring Load Capacities: Be aware of the load capacities of the 15x15 aluminum extrusion. Exceeding these limits can compromise the structure's integrity.

5. Poor Workspace Organization: A cluttered workspace can lead to accidents and mistakes. Keep your area tidy and organized.

Maintenance Tips

To ensure the longevity of your aluminum extrusion assembly, regular maintenance is essential. Here are some tips:

- Clean Regularly: Use a soft cloth and mild detergent to clean the surface of the aluminum. Avoid abrasive cleaners that can scratch the finish.

- Inspect for Damage: Periodically check for any signs of wear or damage, especially at the joints and fasteners.

- Lubricate Moving Parts: If your assembly includes moving parts, apply a suitable lubricant to ensure smooth operation.

Conclusion

Installing 15x15 aluminum extrusions can be a rewarding project, whether for personal use or professional applications. By following these best practices, you can ensure a strong, durable, and aesthetically pleasing result. Remember to take your time during the installation process and prioritize safety and accuracy.

Related Questions

1. What are the typical load capacities for 15x15 aluminum extrusions?

The load capacity of 15x15 aluminum extrusions varies based on the specific alloy and design. Generally, they can support moderate loads, making them suitable for lightweight structures and frames.

2. How do different types of fasteners affect the structural integrity of the assembly?

Using the correct fasteners is crucial for maintaining structural integrity. Bolts provide a stronger hold than screws, while T-slot nuts allow for easy adjustments and disassembly.

3. What are some common applications for 15x15 aluminum extrusions in DIY projects?

Common applications include building frames for 3D printers, workstations, furniture, and custom enclosures for electronics.

4. Can I paint or anodize aluminum extrusions?

Yes, aluminum extrusions can be painted or anodized. Anodizing provides a protective layer and enhances corrosion resistance, while paint can add color and aesthetic appeal.

5. What tools are essential for working with aluminum extrusions?

Essential tools include a miter saw or hacksaw for cutting, a drill for making holes, and various fasteners like T-slot nuts and bolts for assembly.