Content Menu

● Introduction to Extrusion Machinery

>> Types of Extruders

● Extrusion Machinery Manufacturers in Worcestershire

● Applications of Extrusion Machinery

● Benefits of Extrusion Machinery

● Challenges and Future Developments

● Future Trends in Extrusion Technology

● Worcestershire's Manufacturing Infrastructure

● Conclusion

● FAQs

>> 1. What is the primary function of an extruder machine?

>> 2. What are the main types of extruders used in the UK?

>> 3. How does extrusion machinery contribute to sustainability?

>> 4. What are the benefits of using twin-screw extruders?

>> 5. How does the choice of extrusion machinery affect production costs?

● Citations:

Worcestershire, located in the heart of England, is home to a thriving industrial sector, with a significant presence of companies involved in the manufacturing and supply of extrusion machinery. Extrusion machinery plays a crucial role in various industries, including plastics, food, and pharmaceuticals, by shaping raw materials into continuous profiles. This article will explore the best extrusion machinery options available in Worcestershire, highlighting key manufacturers, types of machinery, and their applications.

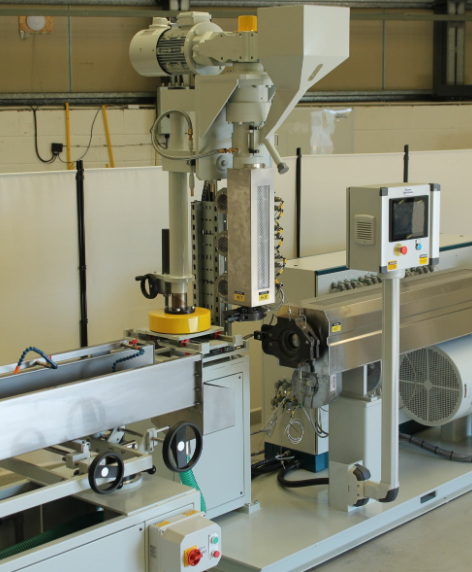

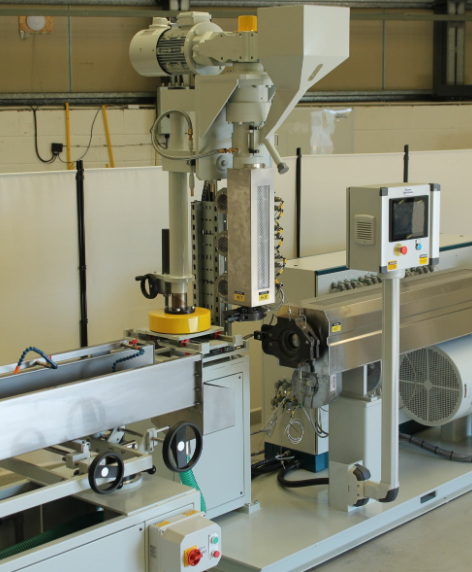

Introduction to Extrusion Machinery

Extrusion machinery is designed to process raw materials by forcing them through a die to create products with specific cross-sectional profiles. The process involves several stages, including feeding, heating, melting, and shaping, followed by cooling and cutting to produce the final product. Common types of extruders include single-screw, twin-screw, and co-extruders, each suited for different materials and applications.

Types of Extruders

1. Single-Screw Extruders: These are the most common type of extruder, used for simple extrusion processes. They are cost-effective and suitable for materials like PVC and polyethylene. In Europe, single-screw machines are widely favored for their cost-effectiveness, streamlined operation, and broad polymer compatibility, with an estimated 62% of thermoplastics extruded in Europe relying on single-screw setups[1].

2. Twin-Screw Extruders: These offer enhanced mixing capabilities, making them ideal for complex formulations and high-throughput applications. They are widely used in the production of compounds and masterbatches. Twin-screw extruders account for roughly 28% of new extruder sales across Germany, Italy, and the Nordic countries, and they excel in advanced compounding scenarios[1].

3. Co-Extruders: Designed to extrude multiple materials simultaneously, co-extruders are used to create composite products with distinct layers or properties.

Extrusion Machinery Manufacturers in Worcestershire

While Worcestershire is not specifically known for a high concentration of extrusion machinery manufacturers, the region benefits from its proximity to major industrial hubs and its strong manufacturing heritage. However, companies like Kimal Manufacturing and Matcon in Worcestershire contribute to the broader machinery manufacturing sector, which supports various industries, including those that utilize extrusion machinery[5].

For plastic extrusion, companies outside Worcestershire but within the UK, such as Goodfish, are notable. Goodfish specializes in delivering high-quality extruded profiles tailored to meet the demanding standards of the construction sector. They operate 36 extrusion lines across two sites in North Wales and offer in-house blending and compounding facilities[2].

Applications of Extrusion Machinery

Extrusion machinery is versatile and serves multiple industries:

- Plastics Industry: Produces pipes, tubes, profiles, and sheets used in construction, automotive, and packaging sectors. The European plastic extrusion machine market is surging due to rising construction activity and the adoption of bio-based polymers[1].

- Food Industry: Used for producing food packaging materials and certain food products like pasta.

- Pharmaceutical Industry: Involved in the production of drug delivery systems and packaging materials.

Benefits of Extrusion Machinery

1. Efficiency: Extrusion machinery allows for continuous production, increasing output and reducing production time. Advances in screw geometries and motor controls have improved energy efficiency by 12% in single-screw extruders[1].

2. Flexibility: Can be adapted to produce a wide range of products by changing the die and material.

3. Cost-Effectiveness: Reduces labor costs by automating the production process.

Challenges and Future Developments

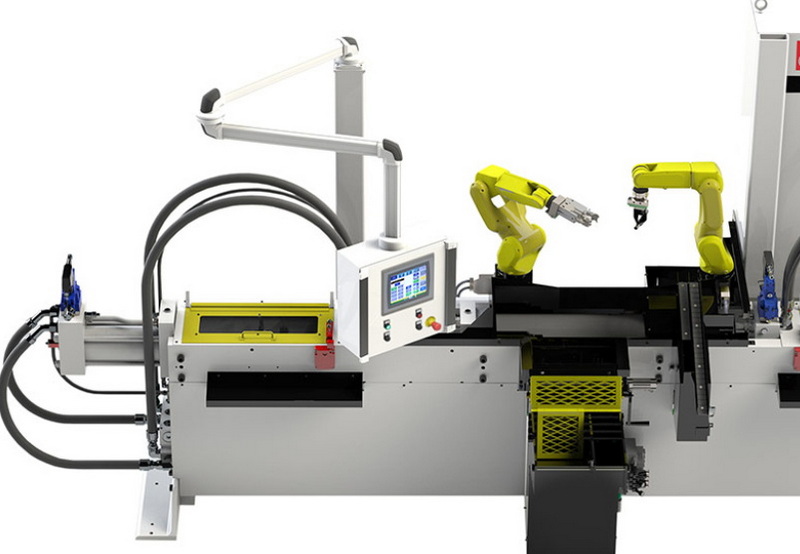

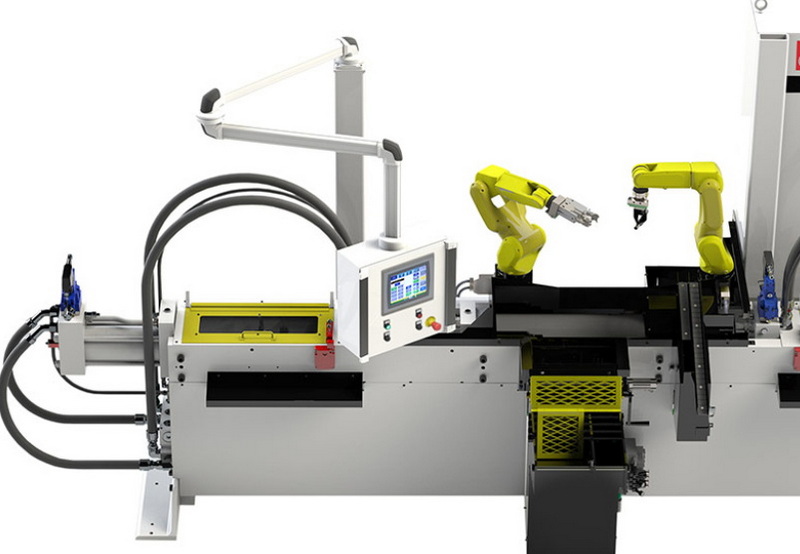

Despite its advantages, the extrusion industry faces challenges such as environmental concerns and technological advancements. Manufacturers are focusing on sustainable practices and developing machinery that can process recycled materials efficiently. The integration of IoT and automation technologies is enhancing connectivity and process optimization, while emerging materials like biodegradable plastics are driving innovation in extrusion technology[4].

Future Trends in Extrusion Technology

The future of extrusion technology holds exciting prospects with the rise of additive manufacturing. 3D printing technologies are evolving to use extrusion processes, opening up opportunities for more complex designs, reduced waste, and greater customization in extrusion manufacturing[4]. Additionally, advancements in smart manufacturing are transforming the way extrusion equipment operates, with real-time process control and predictive maintenance improving production efficiency[4].

Worcestershire's Manufacturing Infrastructure

Worcestershire benefits from its central location, strong manufacturing heritage, and skilled workforce. The county is served by major motorway networks and is within easy reach of two international airports, making it an attractive location for manufacturing companies[3]. The Worcestershire Local Enterprise Partnership has identified advanced manufacturing as one of its key sectors, highlighting the region's potential for growth in this area[3].

Conclusion

Worcestershire offers a robust infrastructure for manufacturing, although it is not specifically renowned for extrusion machinery production. Companies like Goodfish in the broader UK market provide top-notch extrusion solutions. Understanding the types of extruders and their applications is crucial for selecting the right machinery for specific needs. As the industry evolves, focusing on sustainability and technological innovation will be key to future success.

FAQs

1. What is the primary function of an extruder machine?

An extruder machine is used to shape raw materials by forcing them through a die, creating products with specific cross-sectional profiles. This process is essential in industries like plastics and food.

2. What are the main types of extruders used in the UK?

The main types include single-screw, twin-screw, and co-extruders. Each type is suited for different materials and applications, such as simple extrusions, complex formulations, and composite products.

3. How does extrusion machinery contribute to sustainability?

Extrusion machinery can contribute to sustainability by processing recycled materials efficiently and reducing waste. Manufacturers are focusing on developing machinery that supports environmentally friendly practices.

4. What are the benefits of using twin-screw extruders?

Twin-screw extruders offer enhanced mixing capabilities, making them ideal for complex formulations and high-throughput applications. They are widely used in the production of compounds and masterbatches.

5. How does the choice of extrusion machinery affect production costs?

The choice of extrusion machinery can significantly affect production costs by influencing efficiency, material usage, and labor requirements. Single-screw extruders are generally more cost-effective for simple processes, while twin-screw extruders are better suited for complex applications.

Citations:

[1] https://www.globenewswire.com/news-release/2025/01/01/3003246/0/en/Europe-Plastic-Extrusion-Machine-Market-Valuation-is-Skyrocketing-to-Reach-US-3-901-68-Million-by-2033-Astute-Analytica.html

[2] https://www.goodfishgroup.com/plastic-extrusion-company

[3] https://wlep.co.uk/wp-content/uploads/Made-in-Worcestershire-Case-Study.pdf

[4] https://jieyatwinscrew.com/blog/exploring-extrusion-equipment/

[5] https://aeroleads.com/list/top-machinery-manufacturing-companies-in-worcestershire

[6] https://worcestershiregrowthhub.co.uk/chess-plastics-case-study/

[7] https://www.transamshop.co.uk/blogs/news/future-plastic-extrusion-trends-2024

[8] https://www.ptonline.com/articles/get-ready-to-be-blown-away-with-new-extrusion-technology

[9] https://www.bostonmatthews.co.uk

[10] https://www.goodfishgroup.com/understanding-the-plastic-extrusion-process

[11] https://worcestershiregrowthhub.co.uk/category/case-studies/

[12] https://www.polarismarketresearch.com/industry-analysis/north-america-extrusion-machinery-market

[13] https://www.bostonmatthews.co.uk/about-us/

[14] https://us.metoree.com/categories/101797/

[15] https://www.cratersandfreightersworcester.com/about/sustainability/

[16] https://www.magnaplate.com/resources/case-studies

[17] http://southeast.newschannelnebraska.com/story/52530992/extruder-machinery-market-size-and-trends-2025

[18] https://www.linkedin.com/posts/boschhomecomfortgroup_circularity-sustainability-activity-7273353657532792833-msid

[19] https://www.etmm-online.com/jl-goor-expands-fanuc-partnership-with-robodrill-cnc-a-d9899b3ac1f7547e194981af634db389/

[20] https://www.worcester.ac.uk/documents/Sustainable-Waste-Management-Strategy-2020-2030.pdf