Content Menu

● Understanding 4x4 Aluminum Extrusion

● Benefits of 4x4 Aluminum Extrusion

● Best Applications for 4x4 Aluminum Extrusion

>> Structural Frameworks

>> Industrial Equipment

>> Automotive Applications

>> Furniture Design

>> Architectural Applications

>> DIY Projects

>> Robotics and Automation

>> Signage and Displays

>> Marine Applications

>> Aerospace Industry

● Conclusion

● Frequently Asked Questions

>> 1. What is aluminum extrusion?

>> 2. What are the benefits of using 4x4 aluminum extrusion?

>> 3. In which industries is 4x4 aluminum extrusion commonly used?

>> 4. Can I use 4x4 aluminum extrusion for DIY projects?

>> 5. How does aluminum compare to other materials for structural applications?

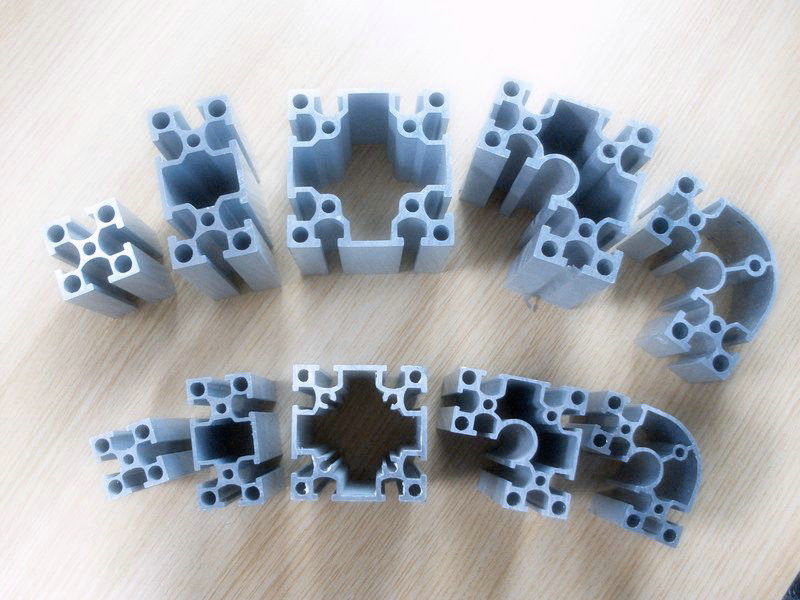

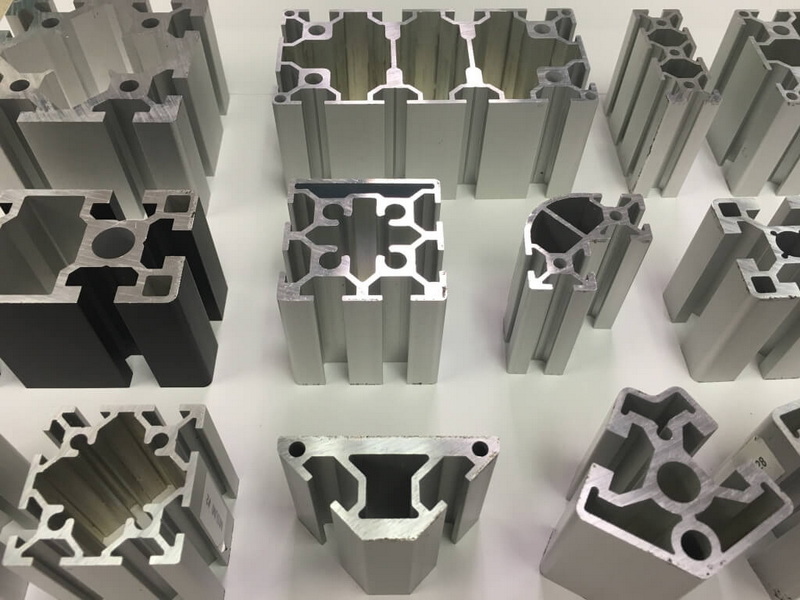

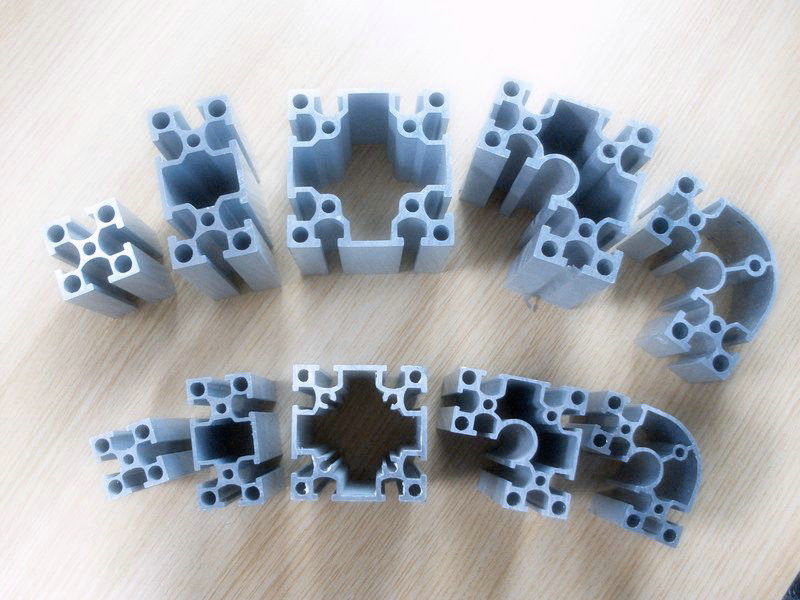

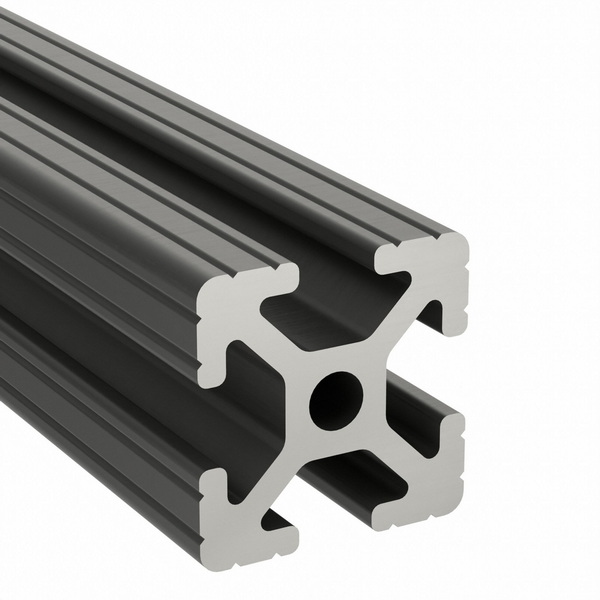

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This process is widely used in various industries due to the material's lightweight, strength, and corrosion resistance. Among the many sizes and shapes available, the 4x4 aluminum extrusion is particularly popular for its versatility and structural integrity. In this article, we will explore the best applications for 4x4 aluminum extrusion, highlighting its benefits and providing insights into its use across different sectors.

Understanding 4x4 Aluminum Extrusion

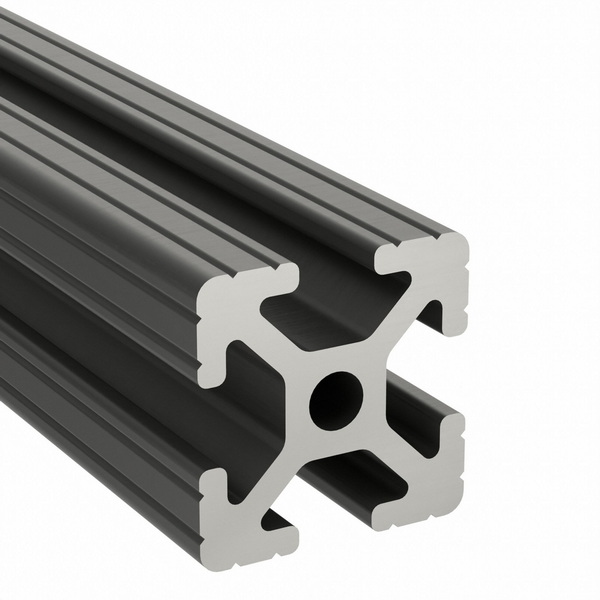

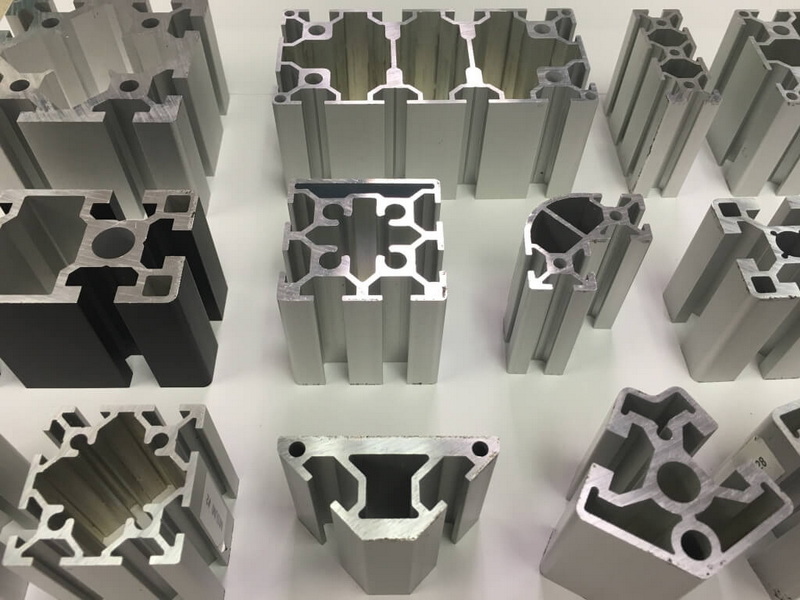

Before diving into its applications, it's essential to understand what 4x4 aluminum extrusion is. The term "4x4" refers to the dimensions of the extrusion, which typically measures 4 inches by 4 inches in cross-section. This size is ideal for various structural applications, providing a balance between strength and weight. The extrusion process allows for the creation of complex shapes that can be tailored to specific needs, making it a preferred choice in many industries.

Benefits of 4x4 Aluminum Extrusion

1. Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport.

2. Strength: Despite its lightweight nature, aluminum has a high strength-to-weight ratio, making it suitable for structural applications.

3. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps prevent corrosion, making it ideal for outdoor applications.

4. Versatility: The extrusion process allows for a wide range of shapes and sizes, enabling customization for specific applications.

5. Cost-Effective: Aluminum extrusion can be more cost-effective than other materials, especially when considering its longevity and low maintenance requirements.

Best Applications for 4x4 Aluminum Extrusion

Structural Frameworks

One of the most common applications for 4x4 aluminum extrusion is in the construction of structural frameworks. These frameworks can be used in buildings, bridges, and other infrastructure projects. The strength and lightweight nature of aluminum make it an excellent choice for supporting structures without adding excessive weight.

In modern construction, the use of aluminum frameworks has gained popularity due to their ability to withstand various environmental conditions while maintaining structural integrity. Architects and engineers often prefer aluminum for its aesthetic appeal and flexibility in design, allowing for innovative architectural solutions.

Industrial Equipment

4x4 aluminum extrusions are widely used in the manufacturing of industrial equipment. They can be found in conveyor systems, machine frames, and workstations. The ability to customize the extrusion allows manufacturers to create equipment that meets specific operational needs while maintaining a lightweight design.

In industries such as food processing, pharmaceuticals, and electronics, the use of aluminum extrusions in equipment design enhances efficiency and safety. The smooth surfaces of aluminum are easy to clean, making them suitable for environments that require strict hygiene standards.

Automotive Applications

In the automotive industry, 4x4 aluminum extrusions are used for various components, including frames, supports, and brackets. The lightweight nature of aluminum helps improve fuel efficiency while maintaining structural integrity. Additionally, aluminum's resistance to corrosion makes it ideal for parts exposed to the elements.

As the automotive industry shifts towards more sustainable practices, the demand for lightweight materials like aluminum is increasing. Manufacturers are exploring innovative ways to incorporate aluminum extrusions into vehicle designs, contributing to reduced emissions and improved performance.

Furniture Design

Aluminum extrusions are increasingly popular in modern furniture design. The sleek, contemporary look of aluminum combined with its durability makes it an attractive choice for furniture manufacturers. 4x4 aluminum extrusions can be used in tables, chairs, and shelving units, providing both aesthetic appeal and structural support.

The versatility of aluminum allows designers to create unique and functional furniture pieces that cater to various styles and preferences. Additionally, aluminum furniture is often lightweight, making it easy to move and rearrange, which is a significant advantage in both residential and commercial settings.

Architectural Applications

Architects often use 4x4 aluminum extrusions in building facades, window frames, and roofing systems. The material's lightweight and corrosion-resistant properties make it suitable for various architectural designs. Additionally, aluminum can be easily finished in different colors and textures, allowing for creative design possibilities.

The use of aluminum in architecture not only enhances the visual appeal of buildings but also contributes to energy efficiency. Aluminum extrusions can be integrated with insulation materials to improve thermal performance, reducing energy consumption in heating and cooling.

DIY Projects

For hobbyists and DIY enthusiasts, 4x4 aluminum extrusions provide a versatile material for various projects. Whether building a custom shelving unit, a garden trellis, or a model, aluminum extrusions can be easily cut and assembled to create unique designs. The lightweight nature of aluminum also makes it easy to work with.

DIY projects using aluminum extrusions can range from simple home improvements to complex engineering designs. The ability to customize the length and shape of the extrusions allows for endless possibilities, encouraging creativity and innovation among makers.

Robotics and Automation

In the field of robotics, 4x4 aluminum extrusions are commonly used to create frames and structures for robotic systems. The lightweight yet strong nature of aluminum allows for the construction of complex robotic designs that require precision and stability. Additionally, the ability to customize the extrusion makes it easier to integrate various components.

As robotics technology advances, the demand for lightweight and durable materials continues to grow. Aluminum extrusions provide the necessary strength and flexibility to support the development of sophisticated robotic systems used in manufacturing, healthcare, and other industries.

Signage and Displays

4x4 aluminum extrusions are also used in the creation of signage and display systems. Their durability and resistance to weathering make them ideal for outdoor signs, while their sleek appearance enhances the visual appeal of indoor displays. The ability to customize the extrusion allows for unique designs that can attract attention.

In retail environments, aluminum extrusions are often used to create eye-catching displays that showcase products effectively. The lightweight nature of aluminum makes it easy to install and reposition displays as needed, providing flexibility for changing marketing strategies.

Marine Applications

In marine environments, 4x4 aluminum extrusions are used for various applications, including boat frames, railings, and supports. Aluminum's resistance to corrosion makes it an ideal choice for marine applications, where exposure to saltwater can be detrimental to other materials. The lightweight nature of aluminum also helps improve the performance of boats and other watercraft.

The use of aluminum in marine construction not only enhances the durability of vessels but also contributes to fuel efficiency. Lighter boats require less power to operate, resulting in lower fuel consumption and reduced environmental impact.

Aerospace Industry

The aerospace industry utilizes 4x4 aluminum extrusions for various components, including aircraft frames and supports. The lightweight nature of aluminum is crucial in aviation, where every ounce counts. Additionally, aluminum's strength and resistance to corrosion make it a preferred material for aerospace applications.

As the aerospace sector continues to innovate, the demand for lightweight materials like aluminum is expected to rise. Manufacturers are exploring advanced aluminum alloys and extrusion techniques to enhance performance and safety in aircraft design.

Conclusion

4x4 aluminum extrusion is a versatile material with a wide range of applications across various industries. Its lightweight, strength, and corrosion resistance make it an ideal choice for structural frameworks, industrial equipment, automotive parts, furniture design, architectural applications, DIY projects, robotics, signage, marine applications, and aerospace components. As technology advances and the demand for lightweight materials increases, the use of aluminum extrusion is expected to grow, further solidifying its place in modern manufacturing and design.

Frequently Asked Questions

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile by forcing it through a die.

2. What are the benefits of using 4x4 aluminum extrusion?

The benefits include lightweight, high strength-to-weight ratio, corrosion resistance, versatility, and cost-effectiveness.

3. In which industries is 4x4 aluminum extrusion commonly used?

It is commonly used in construction, automotive, furniture design, robotics, marine applications, and aerospace.

4. Can I use 4x4 aluminum extrusion for DIY projects?

Yes, 4x4 aluminum extrusion is ideal for DIY projects due to its ease of use and versatility.

5. How does aluminum compare to other materials for structural applications?

Aluminum is lighter and more corrosion-resistant than steel, making it a preferred choice for many structural applications.