Content Menu

● Understanding Aluminum Extrusion

● Benefits of 2x1 Aluminum Extrusion

● Common Applications of 2x1 Aluminum Extrusion

>> Construction and Architecture

>> Automotive Industry

>> Manufacturing and Machinery

>> Electronics and Electrical Enclosures

>> Furniture Design

>> Transportation and Rail Systems

>> Signage and Displays

>> Sports Equipment

● Conclusion

● Frequently Asked Questions

>> 1. What is aluminum extrusion?

>> 2. What are the benefits of using 2x1 aluminum extrusion?

>> 3. In which industries is 2x1 aluminum extrusion commonly used?

>> 4. How does aluminum extrusion contribute to fuel efficiency in vehicles?

>> 5. Can aluminum extrusions be customized for specific applications?

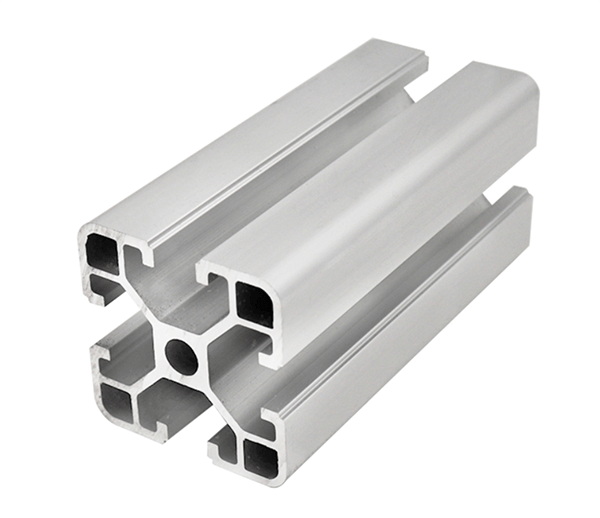

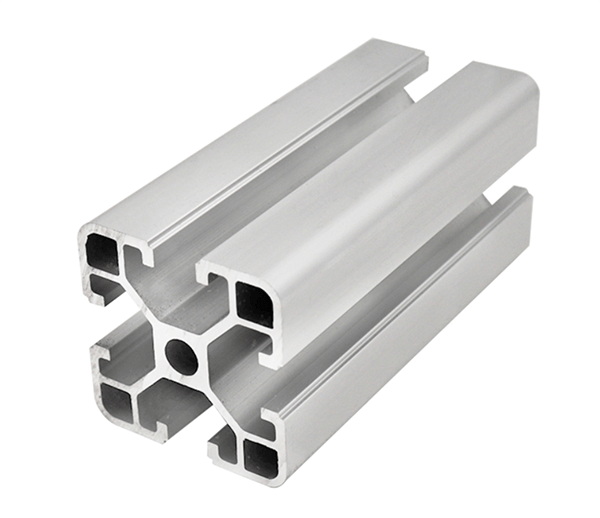

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into specific cross-sectional profiles. Among the various sizes available, the 2x1 aluminum extrusion is particularly popular due to its versatility and strength. This article explores the best applications for 2x1 aluminum extrusion, highlighting its benefits, common uses, and the industries that rely on this material.

Understanding Aluminum Extrusion

Aluminum extrusion involves forcing heated aluminum through a die to create a specific shape. This process allows for the production of complex profiles that can be used in a wide range of applications. The 2x1 aluminum extrusion, with its dimensions of 2 inches by 1 inch, is particularly favored for its balance of strength and weight, making it ideal for structural applications.

Benefits of 2x1 Aluminum Extrusion

1. Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps resist corrosion, making it suitable for outdoor applications.

3. Versatility: The ability to create complex shapes means that 2x1 aluminum extrusions can be tailored to meet specific design requirements.

4. Cost-Effective: Aluminum extrusions can be produced in large quantities, reducing manufacturing costs.

5. Recyclability: Aluminum is 100% recyclable without loss of quality, making it an environmentally friendly choice.

Common Applications of 2x1 Aluminum Extrusion

Construction and Architecture

In the construction industry, 2x1 aluminum extrusions are widely used for framing, window and door frames, and structural supports. Their lightweight nature allows for easier installation, while their strength ensures durability. Architects and builders appreciate the aesthetic appeal of aluminum, which can be finished in various colors and textures. The use of aluminum in construction not only enhances the visual appeal of buildings but also contributes to energy efficiency, as aluminum frames can accommodate thermal breaks to reduce heat transfer.

Automotive Industry

The automotive sector utilizes 2x1 aluminum extrusions for various components, including chassis, body panels, and heat exchangers. The lightweight properties of aluminum help improve fuel efficiency without compromising safety. Additionally, aluminum's ability to dissipate heat makes it ideal for engine components. As the automotive industry moves towards more sustainable practices, the use of aluminum is increasing due to its recyclability and lower environmental impact compared to traditional materials.

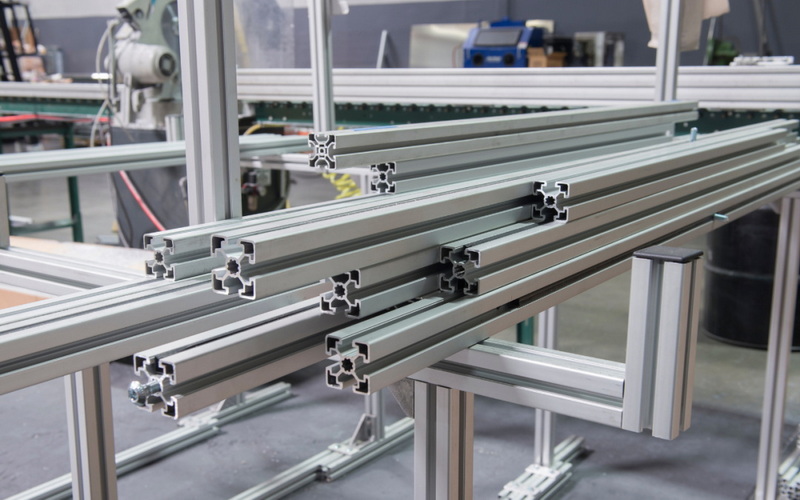

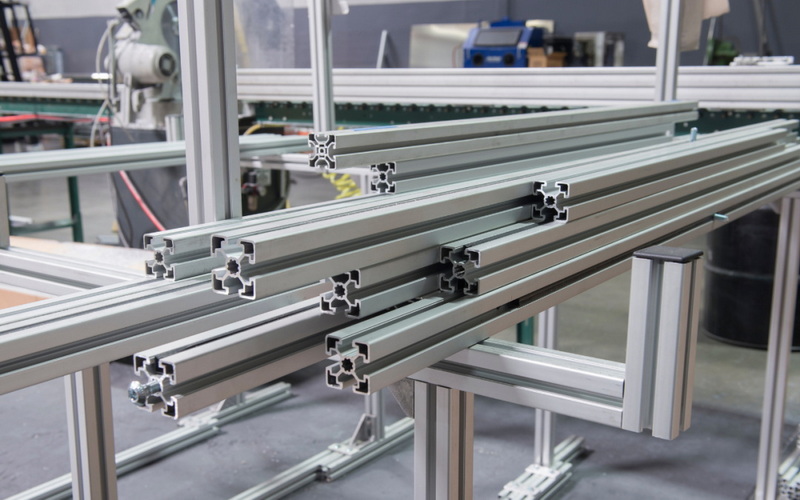

Manufacturing and Machinery

In manufacturing, 2x1 aluminum extrusions are used to create frames for machinery, conveyor systems, and workstations. Their modular design allows for easy assembly and reconfiguration, making them ideal for dynamic manufacturing environments. The extrusions can also be integrated with other materials, such as glass or plastic, to create custom solutions. This adaptability is crucial in modern manufacturing, where efficiency and flexibility are paramount.

Electronics and Electrical Enclosures

The electronics industry often employs 2x1 aluminum extrusions for creating enclosures and heat sinks. Aluminum's excellent thermal conductivity helps dissipate heat from electronic components, ensuring optimal performance. Additionally, the lightweight and durable nature of aluminum makes it suitable for portable electronic devices. The use of aluminum in electronics not only enhances performance but also contributes to the overall design aesthetic, as aluminum can be easily anodized or painted.

Furniture Design

In furniture design, 2x1 aluminum extrusions are used to create modern and sleek furniture pieces. Their lightweight nature allows for easy mobility, while their strength ensures stability. Designers appreciate the versatility of aluminum, which can be finished in various ways to match different aesthetics. From office furniture to outdoor seating, aluminum extrusions provide a contemporary look while maintaining functionality.

Transportation and Rail Systems

The transportation industry utilizes 2x1 aluminum extrusions in the construction of rail systems, buses, and other vehicles. The lightweight properties of aluminum contribute to fuel efficiency and lower emissions. Additionally, aluminum's resistance to corrosion makes it suitable for outdoor applications. As cities expand and public transportation needs grow, aluminum's role in creating efficient and sustainable transport solutions becomes increasingly important.

Signage and Displays

2x1 aluminum extrusions are commonly used in the signage industry for creating frames and supports for signs and displays. Their lightweight nature allows for easy installation, while their durability ensures that signs can withstand outdoor conditions. The ability to customize aluminum extrusions for specific signage needs makes them a popular choice for businesses looking to enhance their visibility.

Sports Equipment

In the sports industry, 2x1 aluminum extrusions are used to manufacture various equipment, including bicycle frames, ski poles, and gym equipment. The lightweight and strong properties of aluminum make it an ideal choice for high-performance sports gear. As athletes seek to improve their performance, the demand for lightweight and durable equipment continues to rise, further driving the use of aluminum in this sector.

Conclusion

The 2x1 aluminum extrusion is a versatile and valuable material used across various industries. Its lightweight, corrosion-resistant, and cost-effective properties make it an ideal choice for applications in construction, automotive, manufacturing, electronics, furniture design, transportation, signage, and sports equipment. As industries continue to innovate, the demand for aluminum extrusions is expected to grow, further solidifying their place in modern manufacturing and design.

Frequently Asked Questions

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into specific cross-sectional profiles by forcing it through a die.

2. What are the benefits of using 2x1 aluminum extrusion?

The benefits include lightweight properties, corrosion resistance, versatility, cost-effectiveness, and recyclability.

3. In which industries is 2x1 aluminum extrusion commonly used?

It is commonly used in construction, automotive, manufacturing, electronics, furniture design, transportation, signage, and sports equipment.

4. How does aluminum extrusion contribute to fuel efficiency in vehicles?

Aluminum's lightweight properties help reduce the overall weight of vehicles, improving fuel efficiency without compromising safety.

5. Can aluminum extrusions be customized for specific applications?

Yes, aluminum extrusions can be tailored to meet specific design requirements, allowing for complex shapes and profiles.