Content Menu

● Understanding 20x80 Aluminum Extrusion

● 1. Building Custom Workbenches

>> Design Considerations

● 2. Creating Shelving Units

>> Steps to Build a Shelving Unit

● 3. Building Frames for 3D Printers

>> Key Features for 3D Printer Frames

● 4. Designing Automated Systems

>> Benefits of Using Aluminum Extrusions in Automation

● 5. Creating Furniture

>> Tips for Designing Aluminum Furniture

● 6. Building Greenhouses

>> Steps to Build a Greenhouse

● 7. Creating Display Stands

>> Designing Display Stands

● 8. Building Racks for Storage

>> Steps to Build a Storage Rack

● 9. Constructing Outdoor Structures

>> Considerations for Outdoor Projects

● 10. Building Custom Tool Holders

>> Steps to Create Tool Holders

● Conclusion

● Frequently Asked Questions

>> 1. What tools do I need to work with 20x80 aluminum extrusion?

>> 2. Can I paint or finish aluminum extrusions?

>> 3. How do I cut aluminum extrusions?

>> 4. Are there any weight limits for structures built with 20x80 aluminum extrusion?

>> 5. Can I use 20x80 aluminum extrusion for outdoor projects?

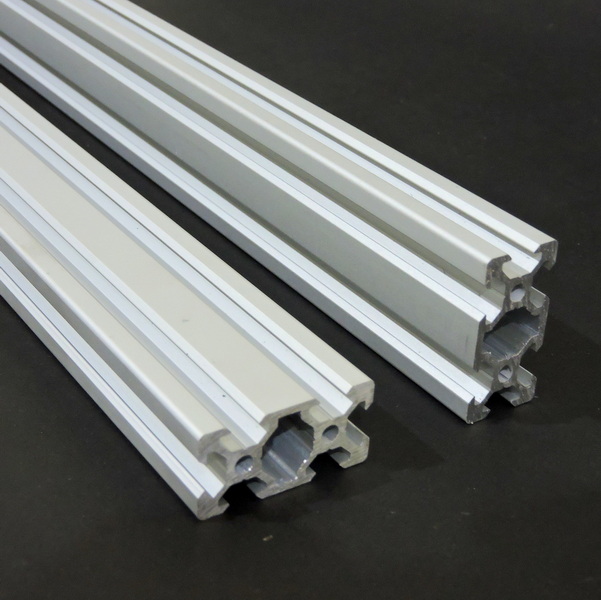

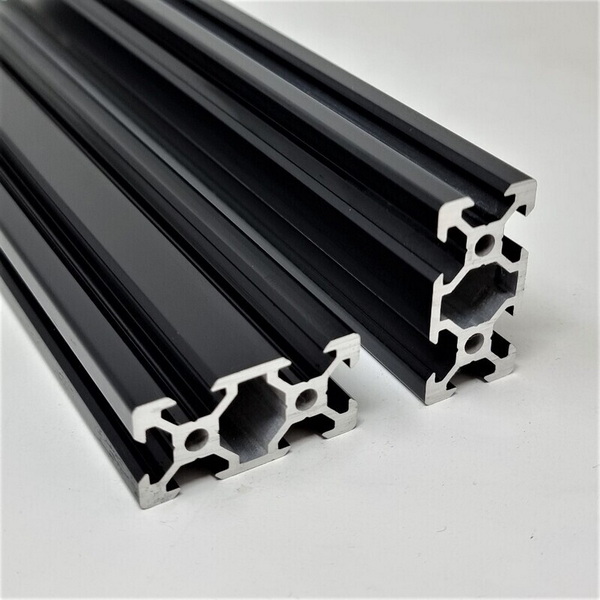

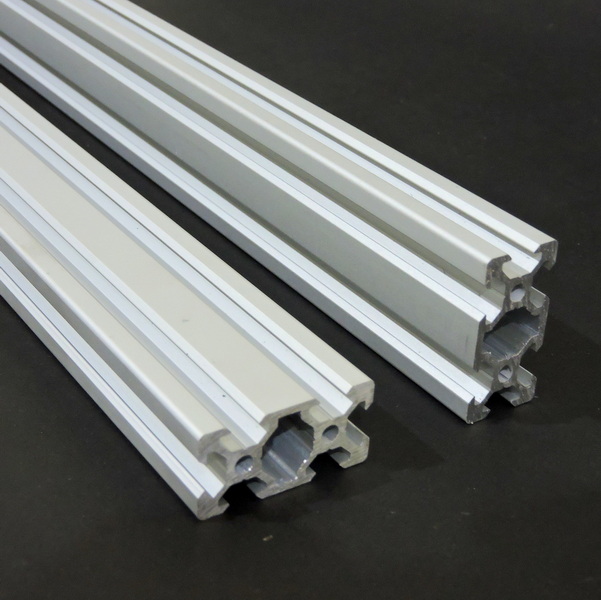

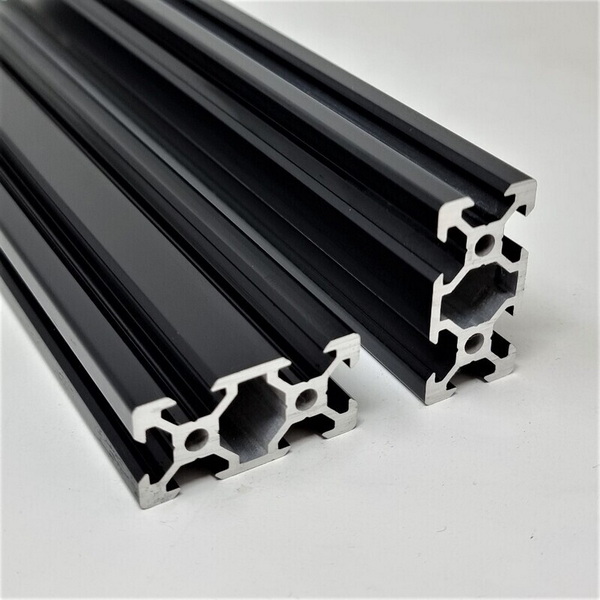

Aluminum extrusions have become a staple in the DIY community, particularly the 20x80 mm size. This versatile profile is favored for its strength, lightweight nature, and ease of assembly. In this article, we will explore the best applications for 20x80 aluminum extrusion in DIY projects, providing insights into how you can leverage this material to create functional and aesthetically pleasing structures.

Understanding 20x80 Aluminum Extrusion

Before diving into specific applications, it's essential to understand what 20x80 aluminum extrusion is. This profile features a rectangular cross-section measuring 20 mm by 80 mm, with T-slots on all four sides. The T-slots allow for easy attachment of various components, making it an ideal choice for modular construction. The aluminum material is lightweight yet strong, resistant to corrosion, and can be easily cut and assembled using standard tools.

1. Building Custom Workbenches

One of the most popular applications for 20x80 aluminum extrusion is in the construction of custom workbenches. The strength and stability of this profile make it perfect for supporting heavy tools and equipment. You can design a workbench tailored to your specific needs, whether for woodworking, electronics, or general crafting.

Design Considerations

When designing a workbench, consider the following:

- Height: Ensure the workbench is at a comfortable height for your tasks. A standard height is typically around 36 inches, but this can vary based on personal preference and the type of work being done.

- Surface Material: Use a durable surface like plywood or MDF for the top. This will provide a solid working area that can withstand wear and tear.

- Storage: Incorporate shelves or drawers using additional aluminum extrusions. This will help keep your workspace organized and efficient.

2. Creating Shelving Units

Another excellent application for 20x80 aluminum extrusion is building shelving units. The modular nature of aluminum extrusions allows you to create adjustable shelves that can be customized to fit any space.

Steps to Build a Shelving Unit

1. Measure Your Space: Determine the dimensions of the area where the shelving unit will be placed. Consider the height, width, and depth to ensure a perfect fit.

2. Cut the Extrusions: Use a miter saw to cut the 20x80 extrusions to the desired lengths. Precision is key to ensure that all pieces fit together seamlessly.

3. Assemble the Frame: Use corner brackets and T-nuts to assemble the frame. This will provide a sturdy structure that can support the weight of the shelves and items placed on them.

4. Add Shelves: Install shelves made from plywood or metal. Ensure that the shelves are securely attached to the frame for stability.

3. Building Frames for 3D Printers

For those interested in 3D printing, 20x80 aluminum extrusion is an ideal material for building frames for 3D printers. The rigidity and stability of the aluminum ensure that your printer remains accurate during operation.

Key Features for 3D Printer Frames

- Stability: The solid structure minimizes vibrations, which is crucial for maintaining print quality.

- Modularity: Easily adjust the frame size to accommodate different printer models. This flexibility allows you to upgrade or modify your printer as needed.

- Ease of Assembly: T-slots allow for quick assembly and disassembly, making it easy to transport or reconfigure your printer setup.

4. Designing Automated Systems

In industrial settings, 20x80 aluminum extrusion is often used to create frames for automated systems. This includes conveyor belts, robotic arms, and other machinery. The lightweight yet strong nature of aluminum makes it suitable for various applications.

Benefits of Using Aluminum Extrusions in Automation

- Lightweight: Reduces the overall weight of the system, improving efficiency and reducing energy consumption.

- Customizable: Easily modify the design to fit specific automation needs. This adaptability is essential in fast-paced industrial environments.

- Durable: Resistant to wear and tear, ensuring longevity and reliability in demanding applications.

5. Creating Furniture

DIY enthusiasts often use 20x80 aluminum extrusion to create modern furniture pieces. From coffee tables to chairs, the sleek design of aluminum can enhance the aesthetic of any room.

Tips for Designing Aluminum Furniture

- Combine Materials: Pair aluminum with wood or glass for a unique look. This combination can create a striking contrast and add warmth to the industrial feel of aluminum.

- Focus on Functionality: Ensure that the furniture is not only stylish but also functional. Consider features like storage or mobility to enhance usability.

- Consider Mobility: Adding wheels can make furniture easier to move, especially for larger pieces like tables or storage units.

6. Building Greenhouses

For gardening enthusiasts, 20x80 aluminum extrusion can be used to construct greenhouses. The lightweight nature of aluminum makes it easy to assemble, while its durability ensures that the structure can withstand various weather conditions.

Steps to Build a Greenhouse

1. Design the Structure: Plan the size and shape of your greenhouse based on the available space and the types of plants you wish to grow.

2. Cut the Extrusions: Prepare the aluminum pieces according to your design. Ensure that all cuts are straight and accurate for a snug fit.

3. Assemble the Frame: Use connectors to build the frame. This will provide a solid foundation for the greenhouse.

4. Add Panels: Use polycarbonate or glass panels for the walls and roof. These materials allow sunlight to penetrate while providing insulation.

7. Creating Display Stands

If you're involved in retail or exhibitions, 20x80 aluminum extrusion can be used to create display stands. These stands are not only functional but can also be designed to be visually appealing.

Designing Display Stands

- Adjustable Heights: Create stands that can be adjusted for different products. This flexibility allows you to showcase items of various sizes effectively.

- Modular Design: Allow for easy reconfiguration based on display needs. This is particularly useful for changing product lines or seasonal displays.

- Aesthetic Appeal: Use finishes and colors to enhance the visual impact. Anodized aluminum can provide a sleek, professional look.

8. Building Racks for Storage

20x80 aluminum extrusion is perfect for building storage racks in garages or workshops. These racks can hold tools, equipment, and other items, keeping your space organized.

Steps to Build a Storage Rack

1. Plan the Layout: Determine how many shelves you need and their spacing. Consider the types of items you will store to ensure adequate support.

2. Cut the Extrusions: Prepare the aluminum pieces for the frame and shelves. Ensure all cuts are precise to maintain structural integrity.

3. Assemble the Rack: Use T-nuts and bolts to secure the structure. This will provide a stable and durable storage solution.

4. Add Shelves: Install shelves made from plywood or metal. Ensure that the shelves are securely attached to the frame for stability.

9. Constructing Outdoor Structures

For outdoor enthusiasts, 20x80 aluminum extrusion can be used to build various structures such as pergolas, canopies, or even outdoor furniture. The weather-resistant properties of aluminum make it suitable for outdoor use.

Considerations for Outdoor Projects

- Corrosion Resistance: Ensure that the aluminum is anodized or coated for added protection against the elements.

- Stability: Design structures to withstand wind and other environmental factors. This may involve anchoring the structure securely to the ground.

- Aesthetic Integration: Choose designs that complement your outdoor space. Consider the surrounding landscape and architecture when planning your project.

10. Building Custom Tool Holders

For those who love organization, creating custom tool holders using 20x80 aluminum extrusion can be a game-changer. These holders can be designed to fit specific tools, keeping your workspace tidy.

Steps to Create Tool Holders

1. Identify Tools: Determine which tools you need to store. This will help you design a holder that meets your specific needs.

2. Design the Holder: Create a design that accommodates the tools securely. Consider using foam inserts or custom brackets for added protection.

3. Cut and Assemble: Use aluminum extrusions to build the holder. Ensure that all pieces fit together snugly for stability.

4. Mounting: Secure the holder to a wall or workbench for easy access. This will help keep your tools organized and within reach.

Conclusion

The versatility of 20x80 aluminum extrusion makes it an excellent choice for a wide range of DIY projects. From workbenches and shelving units to custom furniture and outdoor structures, the applications are virtually limitless. By leveraging the unique properties of aluminum extrusions, you can create functional, durable, and aesthetically pleasing designs that meet your specific needs.

Frequently Asked Questions

1. What tools do I need to work with 20x80 aluminum extrusion?

You will need a miter saw, T-nuts, bolts, and a drill for assembly. A measuring tape and square are also essential for accurate cuts.

2. Can I paint or finish aluminum extrusions?

Yes, aluminum extrusions can be painted or anodized to enhance their appearance and protect against corrosion.

3. How do I cut aluminum extrusions?

Use a miter saw with a fine-toothed blade designed for cutting metal. Ensure you secure the extrusion properly before cutting.

4. Are there any weight limits for structures built with 20x80 aluminum extrusion?

The weight limit depends on the design and assembly of the structure. It's essential to calculate load-bearing capacities based on your specific application.

5. Can I use 20x80 aluminum extrusion for outdoor projects?

Yes, aluminum is naturally resistant to corrosion, making it suitable for outdoor use. However, consider using anodized or coated aluminum for added protection.