Content Menu

● Understanding Aluminum Extrusion

>> Benefits of 2 x 2 Aluminum Extrusion

● Applications of 2 x 2 Aluminum Extrusion

>> 1. Construction and Architecture

>> 2. Manufacturing and Industrial Applications

>> 3. Automotive Industry

>> 4. Furniture Design

>> 5. Electronics and Technology

● Conclusion

● Related Questions

>> 1. What are the typical costs associated with 2 x 2 aluminum extrusion?

>> 2. How does the lifespan of 2 x 2 aluminum extrusion compare to other materials?

>> 3. What are the environmental impacts of producing 2 x 2 aluminum extrusion?

>> 4. Can 2 x 2 aluminum extrusion be customized for specific applications?

>> 5. What maintenance is required for 2 x 2 aluminum extrusion?

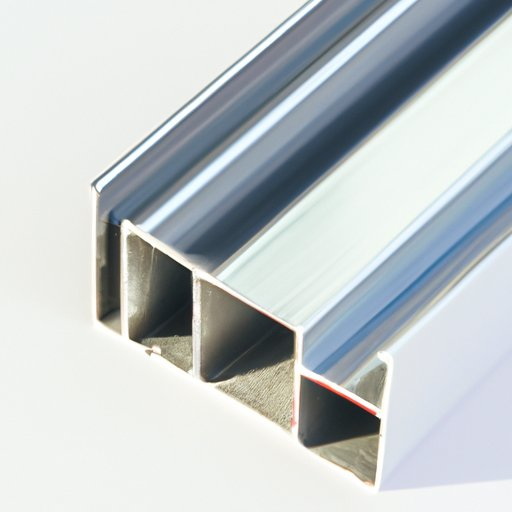

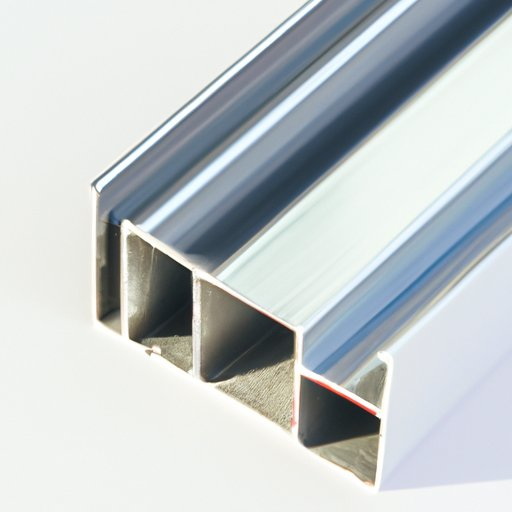

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. The 2 x 2 aluminum extrusion is particularly popular due to its versatility, strength, and lightweight properties. This article explores the best applications for 2 x 2 aluminum extrusion, highlighting its benefits and various uses across different industries.

Understanding Aluminum Extrusion

Aluminum extrusion involves forcing aluminum alloy through a die to create a specific shape. The process allows for the production of complex profiles that can be used in a wide range of applications. The 2 x 2 aluminum extrusion, with its square shape, is especially useful in structural applications where strength and stability are required.

Benefits of 2 x 2 Aluminum Extrusion

1. Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps prevent corrosion.

3. Strength: Despite its lightweight nature, aluminum has a high strength-to-weight ratio, making it suitable for structural applications.

4. Versatility: The extrusion process allows for a wide variety of shapes and sizes, making it adaptable to many uses.

5. Recyclability: Aluminum is 100% recyclable without loss of quality, making it an environmentally friendly choice.

Applications of 2 x 2 Aluminum Extrusion

1. Construction and Architecture

In the construction industry, 2 x 2 aluminum extrusions are commonly used for framing, supports, and architectural features. Their lightweight nature reduces the overall weight of structures, while their strength ensures stability. They are often used in:

- Window Frames: Aluminum extrusions provide a durable and weather-resistant option for window frames.

- Curtain Walls: The strength of 2 x 2 extrusions makes them ideal for supporting curtain wall systems in high-rise buildings.

- Railings and Fencing: Their corrosion resistance makes them suitable for outdoor applications like railings and fencing.

2. Manufacturing and Industrial Applications

In manufacturing, 2 x 2 aluminum extrusions are used in various applications, including:

- Workstations: They can be used to create modular workstations that are both sturdy and flexible.

- Conveyor Systems: The lightweight nature of aluminum allows for easy movement and installation of conveyor systems.

- Machine Frames: Many industrial machines utilize aluminum extrusions for their frames due to their strength and lightweight properties.

3. Automotive Industry

The automotive industry has increasingly turned to aluminum for vehicle manufacturing due to its weight-saving properties. 2 x 2 aluminum extrusions are used in:

- Chassis Components: They provide strength while reducing the overall weight of the vehicle, improving fuel efficiency.

- Interior Structures: Aluminum extrusions are used in the construction of various interior components, contributing to a lighter vehicle.

4. Furniture Design

In furniture design, 2 x 2 aluminum extrusions are popular for creating modern, minimalist designs. They are used in:

- Tables and Desks: The strength and stability of aluminum make it an excellent choice for table and desk frames.

- Shelving Units: Aluminum extrusions can be used to create lightweight yet sturdy shelving solutions.

5. Electronics and Technology

The electronics industry utilizes 2 x 2 aluminum extrusions for various applications, including:

- Heat Sinks: Aluminum's excellent thermal conductivity makes it ideal for heat sinks in electronic devices.

- Enclosures: Many electronic enclosures are made from aluminum extrusions to provide protection while keeping the weight down.

Conclusion

The versatility of 2 x 2 aluminum extrusion makes it an invaluable material across various industries. Its lightweight, strength, and corrosion resistance allow for innovative designs and applications, from construction to automotive and furniture design. As industries continue to seek sustainable and efficient materials, aluminum extrusion will play a crucial role in future developments.

Related Questions

1. What are the typical costs associated with 2 x 2 aluminum extrusion?

The cost of 2 x 2 aluminum extrusion can vary based on factors such as the alloy used, the complexity of the profile, and the quantity ordered. Generally, prices can range from $2 to $5 per pound, but bulk orders may reduce costs significantly.

2. How does the lifespan of 2 x 2 aluminum extrusion compare to other materials?

2 x 2 aluminum extrusions have a long lifespan, often exceeding 30 years when properly maintained. Compared to materials like wood or steel, aluminum is more resistant to corrosion and degradation, making it a durable choice for many applications.

3. What are the environmental impacts of producing 2 x 2 aluminum extrusion?

The production of aluminum has a significant environmental impact, primarily due to the energy-intensive processes involved. However, aluminum is highly recyclable, and using recycled aluminum can reduce energy consumption and environmental footprint significantly.

4. Can 2 x 2 aluminum extrusion be customized for specific applications?

Yes, 2 x 2 aluminum extrusions can be customized in terms of length, thickness, and surface finish to meet specific application requirements. Manufacturers can create unique profiles tailored to the needs of different industries.

5. What maintenance is required for 2 x 2 aluminum extrusion?

Maintenance for 2 x 2 aluminum extrusion is minimal. Regular cleaning with mild soap and water is usually sufficient to maintain its appearance and prevent corrosion. In harsh environments, additional protective coatings may be applied to enhance durability.