Content Menu

● Understanding Aluminum Extrusion

● Applications of 1x3 Aluminum Extrusion

>> 1. Construction and Architecture

>> 2. Automotive Industry

>> 3. Furniture Manufacturing

>> 4. Electronics and Electrical Applications

>> 5. Transportation

● Benefits of Using 1x3 Aluminum Extrusion

● Conclusion

● Related Questions

>> 1. What are the typical costs associated with 1x3 aluminum extrusion?

>> 2. How does the lifespan of 1x3 aluminum extrusion compare to other materials?

>> 3. What are the environmental impacts of producing 1x3 aluminum extrusion?

>> 4. Can 1x3 aluminum extrusion be customized for specific applications?

>> 5. What maintenance is required for 1x3 aluminum extrusion products?

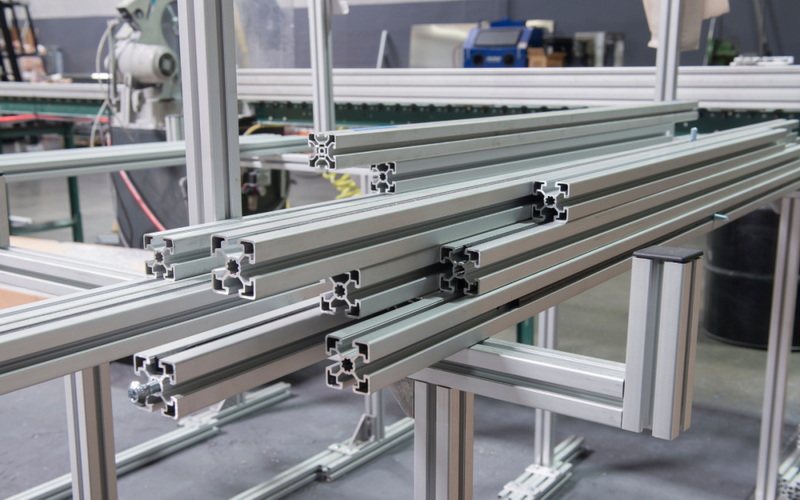

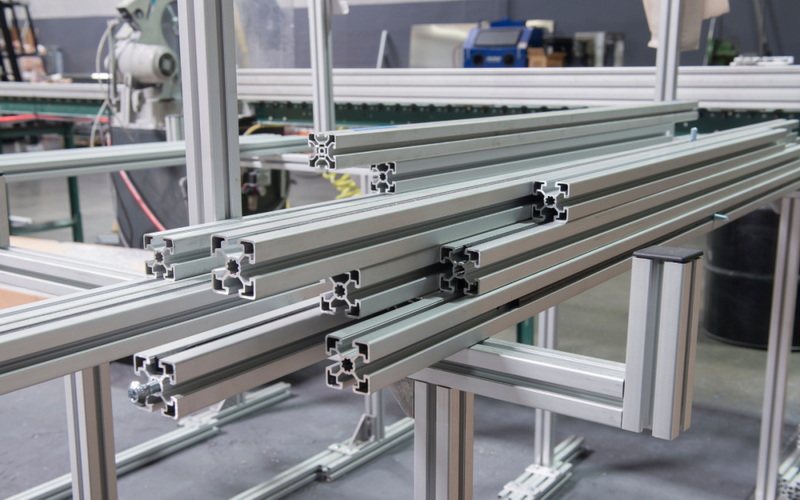

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. The 1x3 aluminum extrusion, with its dimensions of 1 inch by 3 inches, is particularly versatile and widely used across various industries. This article explores the best applications for 1x3 aluminum extrusion, highlighting its benefits, uses, and the reasons behind its popularity.

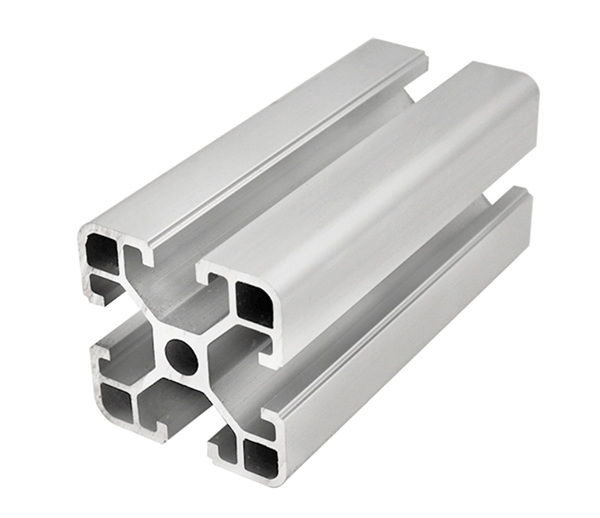

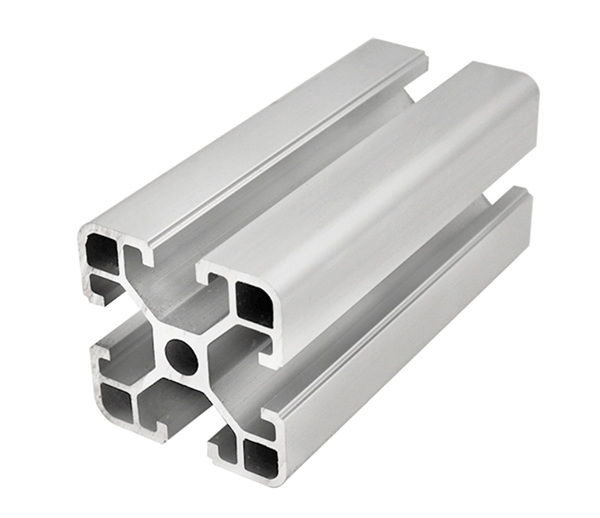

Understanding Aluminum Extrusion

Aluminum extrusion involves forcing aluminum alloy through a die to create a specific shape. This process allows for the production of complex profiles that can be tailored to meet specific requirements. The 1x3 aluminum extrusion is favored for its lightweight yet strong properties, making it ideal for numerous applications.

Applications of 1x3 Aluminum Extrusion

1. Construction and Architecture

One of the primary applications of 1x3 aluminum extrusion is in the construction and architectural sectors. It is commonly used for:

- Window Frames: The strength and durability of aluminum make it an excellent choice for window frames, providing structural integrity while being lightweight.

- Doors: Aluminum extrusions are used in door frames, offering resistance to corrosion and weathering.

- Structural Supports: In commercial buildings, 1x3 aluminum extrusions can serve as structural supports, providing stability without adding excessive weight.

2. Automotive Industry

The automotive industry also benefits significantly from 1x3 aluminum extrusion. Its applications include:

- Chassis Components: The lightweight nature of aluminum helps improve fuel efficiency in vehicles, making it a popular choice for chassis components.

- Interior Trim: Aluminum extrusions are used for various interior trim pieces, providing a modern aesthetic while being durable.

- Heat Exchangers: The thermal conductivity of aluminum makes it suitable for heat exchangers, which are essential for vehicle cooling systems.

3. Furniture Manufacturing

In furniture manufacturing, 1x3 aluminum extrusion is utilized for:

- Frames for Desks and Tables: The strength of aluminum allows for the creation of sturdy yet lightweight furniture frames.

- Shelving Units: Aluminum extrusions can be used to create adjustable shelving systems that are both functional and stylish.

- Outdoor Furniture: The corrosion resistance of aluminum makes it ideal for outdoor furniture, ensuring longevity even in harsh weather conditions.

4. Electronics and Electrical Applications

The electronics industry employs 1x3 aluminum extrusion for various purposes, including:

- Heat Sinks: Aluminum's excellent thermal conductivity makes it ideal for heat sinks, which are crucial for dissipating heat in electronic devices.

- Enclosures: Many electronic devices use aluminum extrusions for their enclosures, providing protection while maintaining a lightweight design.

- Mounting Brackets: The strength and versatility of aluminum allow for the creation of reliable mounting brackets for various electronic components.

5. Transportation

In the transportation sector, 1x3 aluminum extrusion is used in:

- Railings and Handrails: Aluminum extrusions provide safety and support in public transportation systems, such as buses and trains.

- Bicycle Frames: The lightweight nature of aluminum makes it a popular choice for bicycle frames, enhancing performance and ease of handling.

- Cargo Racks: Aluminum extrusions are often used in the construction of cargo racks for vehicles, providing a strong yet lightweight solution for transporting goods.

Benefits of Using 1x3 Aluminum Extrusion

The popularity of 1x3 aluminum extrusion can be attributed to several key benefits:

- Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion and suitable for outdoor applications.

- Versatility: The extrusion process allows for a wide range of shapes and sizes, making it adaptable to various applications.

- Cost-Effective: While the initial cost may be higher than some materials, the durability and low maintenance of aluminum can lead to cost savings over time.

Conclusion

1x3 aluminum extrusion is a highly versatile material with applications spanning multiple industries, including construction, automotive, furniture manufacturing, electronics, and transportation. Its lightweight, durable, and corrosion-resistant properties make it an ideal choice for a wide range of uses. As industries continue to seek efficient and sustainable materials, the demand for aluminum extrusion is likely to grow.

Related Questions

1. What are the typical costs associated with 1x3 aluminum extrusion?

The costs of 1x3 aluminum extrusion can vary based on factors such as the alloy used, the complexity of the profile, and the volume of production. Generally, aluminum extrusion is considered cost-effective due to its durability and low maintenance requirements.

2. How does the lifespan of 1x3 aluminum extrusion compare to other materials?

1x3 aluminum extrusion typically has a longer lifespan than many other materials, such as wood or plastic, especially in outdoor applications where corrosion resistance is crucial.

3. What are the environmental impacts of producing 1x3 aluminum extrusion?

The production of aluminum can have significant environmental impacts, including energy consumption and greenhouse gas emissions. However, aluminum is highly recyclable, which can mitigate some of these effects.

4. Can 1x3 aluminum extrusion be customized for specific applications?

Yes, one of the key advantages of aluminum extrusion is its ability to be customized. Manufacturers can create specific profiles to meet the unique needs of various applications.

5. What maintenance is required for 1x3 aluminum extrusion products?

Aluminum extrusion products generally require minimal maintenance. Regular cleaning with mild soap and water is usually sufficient to maintain their appearance and performance.