Content Menu

● Overview of Aluminum Extrusion

● Applications of 1x1 Aluminum Extrusion

>> 1. Construction and Architecture

>> 2. Automotive Industry

>> 3. Electronics and Electrical Applications

>> 4. Furniture and Interior Design

>> 5. Transportation and Rail

>> 6. Signage and Displays

>> 7. Sports and Recreation

● Benefits of 1x1 Aluminum Extrusion

● Conclusion

● Related Questions

>> 1. What are the typical costs associated with 1x1 aluminum extrusion?

>> 2. How does the lifespan of 1x1 aluminum extrusion compare to other materials?

>> 3. What are the environmental impacts of producing 1x1 aluminum extrusion?

>> 4. Can 1x1 aluminum extrusion be used in outdoor applications?

>> 5. What are the design considerations when using 1x1 aluminum extrusion?

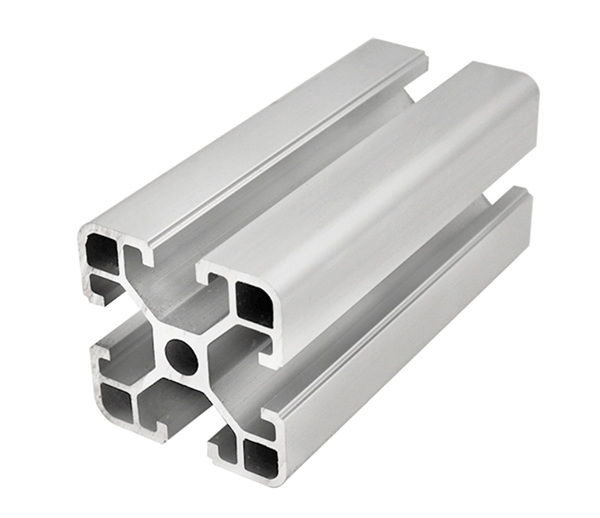

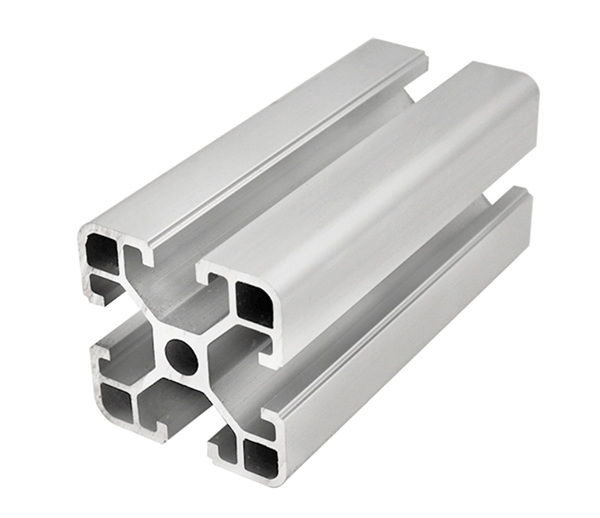

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. The 1x1 aluminum extrusion, characterized by its square shape and versatile dimensions, is particularly popular across various industries due to its lightweight, strength, and corrosion resistance. This article explores the best applications for 1x1 aluminum extrusion, highlighting its benefits and versatility.

Overview of Aluminum Extrusion

Aluminum extrusion involves forcing aluminum alloy through a die to create a specific shape. This process allows for the production of complex profiles that can be tailored to meet specific requirements. The 1x1 aluminum extrusion is commonly used in applications where structural integrity and aesthetic appeal are essential.

Applications of 1x1 Aluminum Extrusion

1. Construction and Architecture

In the construction industry, 1x1 aluminum extrusions are widely used for framing, window and door systems, and architectural features. Their lightweight nature makes them easy to handle and install, while their strength provides durability. Additionally, aluminum's resistance to corrosion ensures that structures maintain their appearance and integrity over time.

2. Automotive Industry

The automotive sector utilizes 1x1 aluminum extrusions for various components, including chassis, supports, and trim. The lightweight properties of aluminum contribute to improved fuel efficiency and performance in vehicles. Moreover, aluminum's ability to withstand harsh environmental conditions makes it an ideal choice for automotive applications.

3. Electronics and Electrical Applications

In the electronics industry, 1x1 aluminum extrusions are often used for heat sinks, enclosures, and structural components. Aluminum's excellent thermal conductivity helps dissipate heat effectively, protecting sensitive electronic components. Additionally, the aesthetic appeal of aluminum makes it a popular choice for consumer electronics.

4. Furniture and Interior Design

1x1 aluminum extrusions are increasingly used in furniture design, providing a modern and sleek look. They are commonly found in tables, chairs, and shelving units. The strength and lightweight nature of aluminum allow for innovative designs that are both functional and stylish.

5. Transportation and Rail

In the transportation sector, 1x1 aluminum extrusions are used in the construction of railings, supports, and structural components for trains and buses. Their lightweight properties contribute to overall weight reduction, enhancing fuel efficiency and performance. Additionally, aluminum's resistance to corrosion ensures longevity in outdoor applications.

6. Signage and Displays

Aluminum extrusions are frequently used in the signage industry for creating frames and supports for signs and displays. The 1x1 profile provides a clean and professional look, while the durability of aluminum ensures that signs withstand various weather conditions.

7. Sports and Recreation

In the sports and recreation industry, 1x1 aluminum extrusions are used in the construction of equipment such as bicycles, gym equipment, and sporting goods. The lightweight nature of aluminum enhances performance, while its strength ensures safety and durability.

Benefits of 1x1 Aluminum Extrusion

1x1 aluminum extrusions offer numerous advantages, making them a preferred choice in various applications:

- Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, preventing rust and corrosion.

- Strength: Despite its lightweight nature, aluminum is strong and can withstand significant loads.

- Versatility: The extrusion process allows for a wide range of shapes and sizes, catering to diverse needs.

- Aesthetic Appeal: Aluminum has a modern look that enhances the visual appeal of products and structures.

Conclusion

The versatility of 1x1 aluminum extrusion makes it an invaluable material across multiple industries. From construction to electronics, its lightweight, strength, and corrosion resistance contribute to innovative designs and efficient applications. As industries continue to evolve, the demand for aluminum extrusion is likely to grow, further solidifying its place in modern manufacturing.

Related Questions

1. What are the typical costs associated with 1x1 aluminum extrusion?

The costs of 1x1 aluminum extrusion can vary based on factors such as the complexity of the design, the quantity ordered, and the specific alloy used. Generally, custom extrusions may have higher costs due to tooling and setup, while standard profiles can be more economical.

2. How does the lifespan of 1x1 aluminum extrusion compare to other materials?

1x1 aluminum extrusions typically have a long lifespan, often exceeding that of materials like wood or plastic, especially in outdoor applications. Aluminum's resistance to corrosion and environmental factors contributes to its durability.

3. What are the environmental impacts of producing 1x1 aluminum extrusion?

The production of aluminum extrusion has environmental impacts, including energy consumption and greenhouse gas emissions. However, aluminum is highly recyclable, and using recycled aluminum can significantly reduce these impacts.

4. Can 1x1 aluminum extrusion be used in outdoor applications?

Yes, 1x1 aluminum extrusion is suitable for outdoor applications due to its corrosion resistance and durability. It is commonly used in outdoor furniture, signage, and architectural features.

5. What are the design considerations when using 1x1 aluminum extrusion?

When designing with 1x1 aluminum extrusion, considerations include load-bearing requirements, thermal expansion, and joining methods. It's essential to ensure that the design accommodates these factors for optimal performance.

This comprehensive overview of 1x1 aluminum extrusion highlights its diverse applications and benefits, making it a crucial material in modern manufacturing and design.