Content Menu

● Understanding Aluminum Extrusion

● Benefits of 10x10 Aluminum Extrusion

● Applications of 10x10 Aluminum Extrusion

>> 1. Construction and Architecture

>> 2. Automotive Industry

>> 3. Electronics and Electrical Applications

>> 4. Furniture Design

>> 5. Transportation

● Conclusion

● Frequently Asked Questions

>> 1. What are the typical costs associated with 10x10 aluminum extrusion?

>> 2. How does the lifespan of 10x10 aluminum extrusion compare to other materials?

>> 3. What are the environmental impacts of producing and using 10x10 aluminum extrusion?

>> 4. Can 10x10 aluminum extrusion be customized for specific applications?

>> 5. Is 10x10 aluminum extrusion suitable for outdoor use?

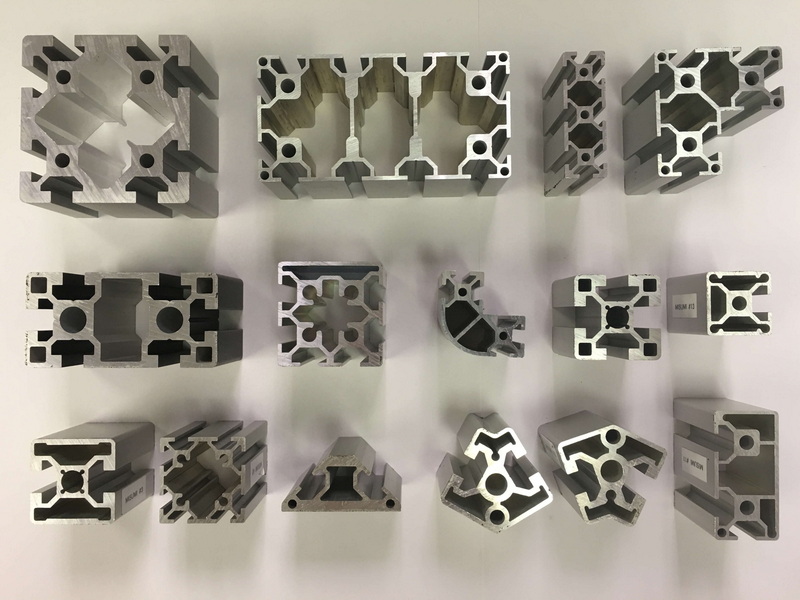

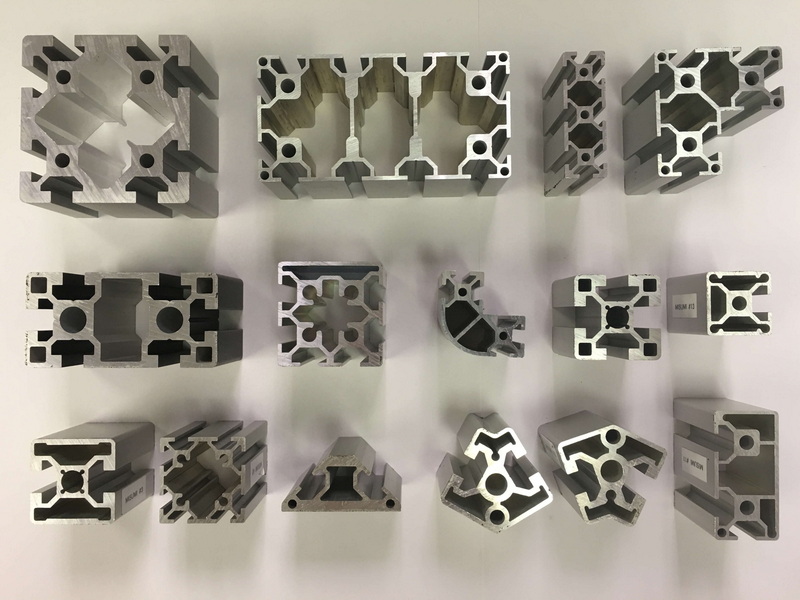

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. The 10x10 aluminum extrusion, with its square shape and versatile properties, is particularly popular across various industries. This article explores the best applications for 10x10 aluminum extrusion, highlighting its benefits, uses, and the reasons behind its widespread adoption.

Understanding Aluminum Extrusion

Aluminum extrusion involves forcing aluminum alloy through a die to create a specific shape. The process allows for a high degree of customization, making it suitable for a wide range of applications. The 10x10 aluminum extrusion is characterized by its square profile, which provides structural integrity and aesthetic appeal.

Benefits of 10x10 Aluminum Extrusion

1. Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport. This property is particularly beneficial in applications where weight reduction is crucial, such as in the automotive and aerospace industries.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps resist corrosion. This makes 10x10 aluminum extrusion ideal for outdoor applications or environments with high humidity.

3. Strength and Durability: Despite its lightweight nature, aluminum is strong and durable. The 10x10 profile can support substantial loads, making it suitable for structural applications.

4. Versatility: The extrusion process allows for a variety of shapes and sizes, enabling designers to create custom solutions tailored to specific needs.

5. Recyclability: Aluminum is 100% recyclable without loss of quality, making it an environmentally friendly choice for manufacturers and consumers alike.

Applications of 10x10 Aluminum Extrusion

1. Construction and Architecture

In the construction industry, 10x10 aluminum extrusion is widely used for framing, window and door systems, and architectural facades. Its lightweight nature reduces the overall weight of structures, while its strength ensures stability. Additionally, aluminum's aesthetic appeal allows for modern designs that enhance the visual appeal of buildings.

2. Automotive Industry

The automotive sector utilizes 10x10 aluminum extrusion for various components, including chassis, brackets, and structural supports. The lightweight properties of aluminum contribute to improved fuel efficiency and performance. Furthermore, aluminum's resistance to corrosion extends the lifespan of automotive parts, reducing maintenance costs.

3. Electronics and Electrical Applications

In the electronics industry, 10x10 aluminum extrusion is often used for heat sinks, enclosures, and mounting brackets. Aluminum's excellent thermal conductivity helps dissipate heat from electronic components, ensuring optimal performance. The extrusion process allows for precise dimensions, which is crucial for fitting electronic devices.

4. Furniture Design

Aluminum extrusion is increasingly popular in furniture design, particularly for modern and minimalist styles. The 10x10 profile can be used for table legs, frames, and shelving units. Its lightweight nature makes it easy to move furniture, while its durability ensures long-lasting use.

5. Transportation

In transportation, 10x10 aluminum extrusion is used in the manufacturing of trailers, railings, and other structural components. The lightweight nature of aluminum helps reduce the overall weight of vehicles, improving fuel efficiency. Additionally, aluminum's resistance to corrosion is beneficial for components exposed to the elements.

Conclusion

The 10x10 aluminum extrusion is a versatile and valuable material across various industries. Its lightweight, corrosion-resistant, and durable properties make it an ideal choice for applications in construction, automotive, electronics, furniture design, and transportation. As industries continue to seek innovative solutions, the demand for aluminum extrusion is likely to grow, further solidifying its place in modern manufacturing.

Frequently Asked Questions

1. What are the typical costs associated with 10x10 aluminum extrusion?

The cost of 10x10 aluminum extrusion can vary based on factors such as the alloy used, the complexity of the design, and the quantity ordered. Generally, aluminum extrusion is cost-effective for large production runs due to the efficiency of the manufacturing process. For smaller quantities, prices may be higher due to setup costs.

2. How does the lifespan of 10x10 aluminum extrusion compare to other materials?

10x10 aluminum extrusion typically has a longer lifespan than many other materials, such as wood or plastic, especially in outdoor applications. Its resistance to corrosion and ability to withstand environmental factors contribute to its durability, making it a preferred choice for long-term use.

3. What are the environmental impacts of producing and using 10x10 aluminum extrusion?

The production of aluminum has environmental impacts, including energy consumption and greenhouse gas emissions. However, aluminum is highly recyclable, which mitigates some of these effects. Using recycled aluminum for extrusion significantly reduces energy use and environmental impact compared to producing new aluminum from raw materials.

4. Can 10x10 aluminum extrusion be customized for specific applications?

Yes, one of the key advantages of aluminum extrusion is its ability to be customized. Manufacturers can create specific profiles and dimensions to meet the unique requirements of various applications, making it a flexible solution for designers and engineers.

5. Is 10x10 aluminum extrusion suitable for outdoor use?

Absolutely. The corrosion resistance of aluminum makes 10x10 aluminum extrusion an excellent choice for outdoor applications. It can withstand exposure to moisture, UV rays, and other environmental factors without deteriorating, making it ideal for outdoor furniture, architectural elements, and more.