Content Menu

● Structural Frameworks

>> Benefits:

● Industrial Machinery

>> Benefits:

● Furniture and Fixtures

>> Benefits:

● Transportation

>> Benefits:

● Architectural Applications

>> Benefits:

● Electronics and Electrical Enclosures

>> Benefits:

● DIY Projects

>> Benefits:

● Conclusion

● Frequently Asked Questions

>> 1. What is aluminum extrusion?

>> 2. What are the benefits of using 1 x 2 aluminum extrusion?

>> 3. Can aluminum extrusions be recycled?

>> 4. What industries commonly use aluminum extrusions?

>> 5. How can I work with aluminum extrusions for DIY projects?

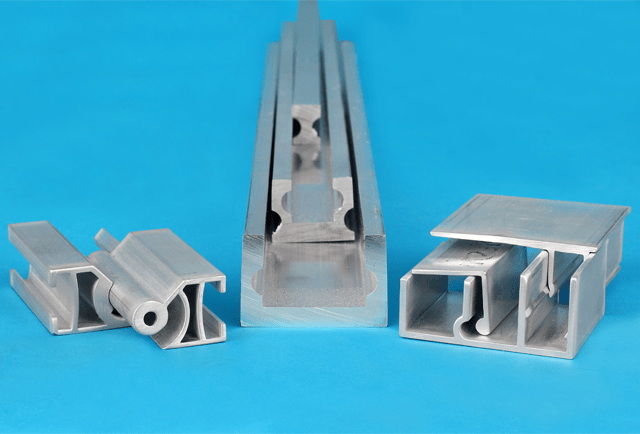

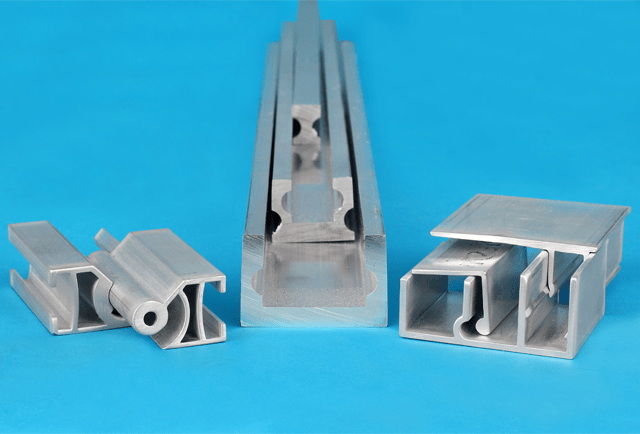

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. The process involves forcing aluminum through a die, which gives it a specific shape. One of the most popular sizes in the market is the 1 x 2 aluminum extrusion. This versatile profile is used in a wide range of applications across various industries due to its lightweight, strength, and corrosion resistance. In this article, we will explore the best applications for 1 x 2 aluminum extrusion, highlighting its benefits and providing insights into its uses.

Structural Frameworks

One of the primary applications of 1 x 2 aluminum extrusion is in the construction of structural frameworks. These frameworks are essential in various industries, including construction, manufacturing, and automation. The lightweight nature of aluminum makes it an ideal choice for building frames that need to support significant loads without adding excessive weight.

Benefits:

- Strength-to-Weight Ratio: Aluminum has a high strength-to-weight ratio, making it suitable for structures that require both strength and lightness. This property is particularly beneficial in applications where reducing weight is crucial, such as in aerospace and automotive industries.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps it resist corrosion, making it ideal for outdoor applications. This characteristic ensures that structures maintain their integrity and appearance over time, even when exposed to harsh environmental conditions.

Industrial Machinery

1 x 2 aluminum extrusions are widely used in the construction of industrial machinery. They can be found in conveyor systems, assembly lines, and robotic arms. The extrusions can be easily cut and assembled to create custom machinery that meets specific operational needs.

Benefits:

- Customization: The ability to easily modify the length and shape of aluminum extrusions allows for tailored solutions in machinery design. This flexibility is essential in industries where machinery must adapt to different production processes or product types.

- Ease of Assembly: Aluminum extrusions can be quickly assembled using standard fasteners, reducing downtime during installation. This efficiency is crucial in manufacturing environments where time is money, and minimizing production delays is a priority.

Furniture and Fixtures

Another popular application for 1 x 2 aluminum extrusion is in the design and construction of furniture and fixtures. The sleek and modern appearance of aluminum makes it a favorite material for contemporary furniture designs, including tables, chairs, and shelving units.

Benefits:

- Aesthetic Appeal: Aluminum provides a modern look that can enhance the overall design of furniture. Its clean lines and ability to be anodized or painted allow for a variety of finishes that can complement any interior design style.

- Durability: Aluminum furniture is resistant to rust and corrosion, ensuring longevity even in high-traffic areas. This durability makes aluminum a practical choice for both residential and commercial furniture applications.

Transportation

In the transportation industry, 1 x 2 aluminum extrusions are used in various applications, including the construction of vehicle frames, trailers, and railings. The lightweight nature of aluminum helps improve fuel efficiency in vehicles while maintaining structural integrity.

Benefits:

- Fuel Efficiency: Reducing the weight of vehicles can lead to significant fuel savings over time. Lighter vehicles require less energy to operate, which is increasingly important in an era of rising fuel costs and environmental concerns.

- Recyclability: Aluminum is 100% recyclable, making it an environmentally friendly choice for transportation applications. This sustainability aspect is becoming more critical as consumers and manufacturers alike seek to reduce their carbon footprints.

Architectural Applications

Aluminum extrusions are also widely used in architectural applications, such as window frames, curtain walls, and roofing systems. The 1 x 2 profile is particularly useful for creating strong and lightweight structures that can withstand various environmental conditions.

Benefits:

- Thermal Efficiency: Aluminum can be designed to improve thermal performance in buildings, contributing to energy savings. By incorporating thermal breaks and insulation, aluminum extrusions can help maintain comfortable indoor temperatures while reducing heating and cooling costs.

- Design Flexibility: The versatility of aluminum extrusions allows architects to create innovative designs that enhance the aesthetic appeal of buildings. This flexibility enables the integration of aluminum into various architectural styles, from modern to traditional.

Electronics and Electrical Enclosures

1 x 2 aluminum extrusions are commonly used in the manufacturing of electronic enclosures and heat sinks. The excellent thermal conductivity of aluminum helps dissipate heat from electronic components, ensuring optimal performance and longevity.

Benefits:

- Heat Dissipation: Aluminum's thermal properties make it ideal for applications where heat management is critical. Effective heat dissipation is essential in preventing overheating, which can lead to component failure and reduced lifespan.

- Protection: Aluminum enclosures provide a protective barrier for sensitive electronic components against dust and moisture. This protection is vital in maintaining the functionality and reliability of electronic devices, especially in harsh environments.

DIY Projects

For hobbyists and DIY enthusiasts, 1 x 2 aluminum extrusions offer endless possibilities for creating custom projects. From building model structures to crafting unique furniture pieces, the versatility of aluminum extrusions makes them a popular choice for personal projects.

Benefits:

- Ease of Use: Aluminum extrusions can be easily cut and assembled, making them accessible for DIY projects. This user-friendliness encourages creativity and experimentation among hobbyists.

- Creative Freedom: The variety of shapes and sizes available allows for creative expression in project design. Whether constructing a simple shelf or a complex model, aluminum extrusions provide the flexibility needed to bring ideas to life.

Conclusion

The 1 x 2 aluminum extrusion is a versatile and widely used profile in various industries. Its lightweight, strength, and corrosion resistance make it an ideal choice for structural frameworks, industrial machinery, furniture, transportation, architectural applications, electronics, and DIY projects. As technology advances and the demand for sustainable materials increases, aluminum extrusion will continue to play a crucial role in modern manufacturing and design.

Frequently Asked Questions

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile by forcing it through a die. This process allows for the creation of complex shapes that are strong yet lightweight.

2. What are the benefits of using 1 x 2 aluminum extrusion?

The benefits include a high strength-to-weight ratio, corrosion resistance, ease of assembly, and customization options. These characteristics make it suitable for a wide range of applications across different industries.

3. Can aluminum extrusions be recycled?

Yes, aluminum is 100% recyclable, making it an environmentally friendly material choice. Recycling aluminum requires only a fraction of the energy needed to produce new aluminum, contributing to sustainability efforts.

4. What industries commonly use aluminum extrusions?

Industries such as construction, transportation, electronics, and furniture design commonly use aluminum extrusions. Their versatility and performance characteristics make them suitable for various applications.

5. How can I work with aluminum extrusions for DIY projects?

Aluminum extrusions can be easily cut and assembled using standard fasteners, making them accessible for various DIY projects. Many suppliers offer kits and accessories that simplify the assembly process, allowing for creative and functional designs.

This comprehensive exploration of 1 x 2 aluminum extrusion applications highlights its significance in modern manufacturing and design, showcasing its versatility and benefits across multiple sectors.