Content Menu

● Introduction

● Understanding CAD Software

● Key Features of Aluminum Design Software

>> 3D Modeling Capabilities

>> Simulation Tools for Testing Designs

>> Customization Options for Unique Profiles

● Benefits of Using CAD Software in Aluminum Extrusion

>> Increased Design Accuracy and Reduced Errors

>> Time-Saving in the Design Process

>> Enhanced Collaboration Among Design Teams

● Case Studies

>> Company A: Automotive Industry

>> Company B: Aerospace Sector

>> Company C: Construction Industry

● Tips for Choosing the Right Software

>> Assess Your Needs

>> Look for User-Friendly Interfaces

>> Evaluate Customer Support and Training

>> Consider Integration with Existing Systems

>> Read Reviews and Case Studies

● Conclusion

● Frequently Asked Questions

>> 1. What is aluminum extrusion software?

>> 2. How does CAD software improve the aluminum extrusion process?

>> 3. What are the key features to look for in aluminum extrusion software?

>> 4. Can aluminum extrusion software help reduce production costs?

>> 5. Are there specific industries that benefit most from aluminum extrusion software?

Introduction

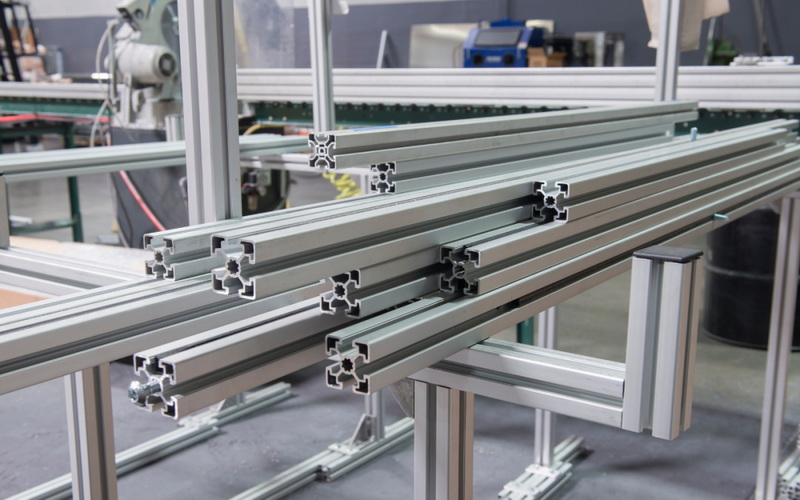

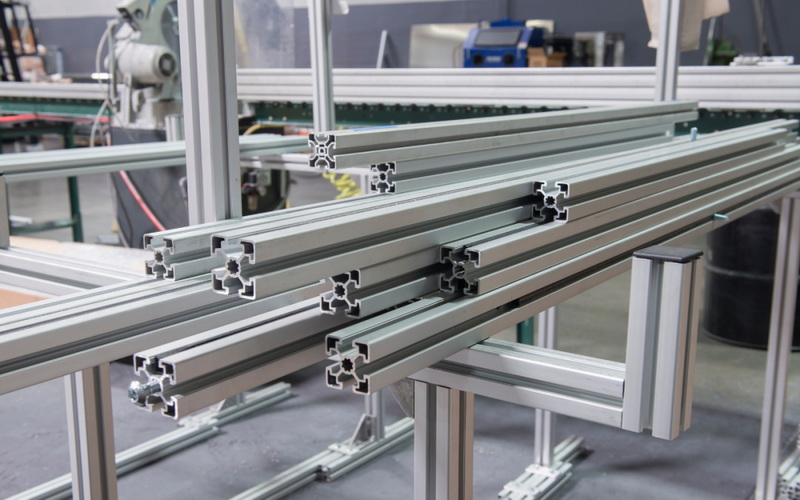

Aluminum extrusion is a vital process in the manufacturing industry, allowing for the creation of complex shapes and profiles that are lightweight yet strong. The efficiency and effectiveness of this process can be significantly enhanced through the use of specialized aluminum extrusion software. This software not only streamlines the design process but also improves accuracy, reduces waste, and ultimately saves time and costs. In this article, we will explore the best aluminum extrusion software options available today, their features, benefits, and how they can transform your design projects.

Understanding CAD Software

Computer-Aided Design (CAD) software is a crucial tool in modern engineering and manufacturing. It allows designers to create precise drawings and models of their projects, facilitating better visualization and planning. In the context of aluminum extrusion, CAD software provides the necessary tools to design intricate profiles and simulate the extrusion process.

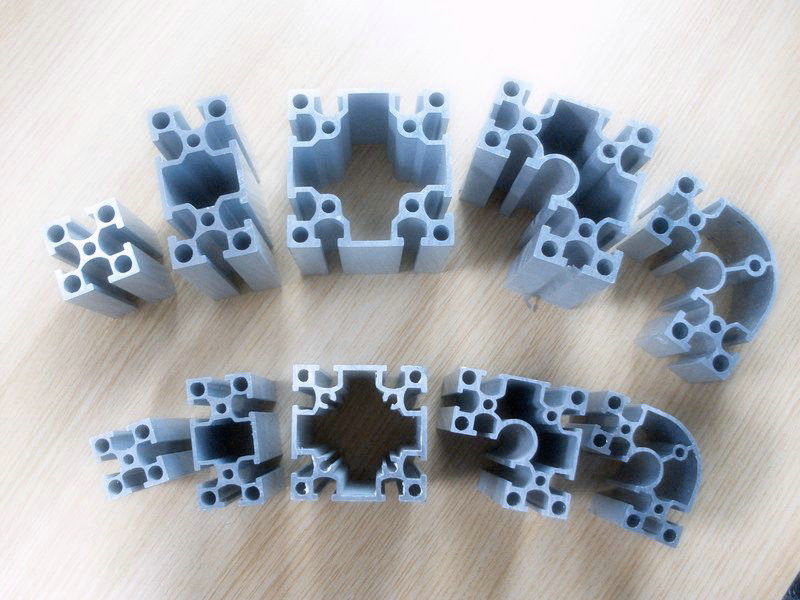

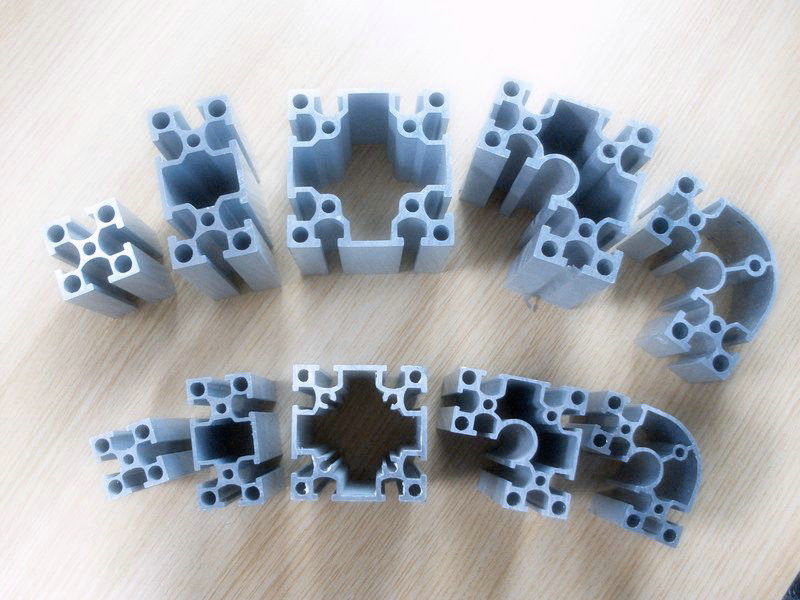

There are various types of CAD software available for aluminum extrusion, each offering unique features tailored to different aspects of the design and manufacturing process. Some software focuses on 3D modeling, while others emphasize simulation and analysis, making it essential to choose the right tool for your specific needs.

Key Features of Aluminum Design Software

When selecting aluminum extrusion software, it is important to consider the key features that can enhance your design process. Here are some of the most valuable features to look for:

3D Modeling Capabilities

One of the primary advantages of aluminum extrusion software is its ability to create detailed 3D models. This feature allows designers to visualize their projects in a realistic manner, making it easier to identify potential issues before production begins. With advanced 3D modeling tools, users can manipulate designs, adjust dimensions, and explore various configurations.

Simulation Tools for Testing Designs

Simulation tools are essential for testing the feasibility of designs before they are manufactured. These tools allow users to simulate the extrusion process, analyzing how the material will behave under different conditions. By identifying potential problems early in the design phase, manufacturers can avoid costly mistakes and ensure that their products meet quality standards.

Customization Options for Unique Profiles

Aluminum extrusion often requires custom profiles to meet specific project requirements. The best aluminum extrusion software offers extensive customization options, enabling users to create unique shapes and designs. This flexibility is crucial for industries that demand tailored solutions, such as automotive, aerospace, and construction.

Benefits of Using CAD Software in Aluminum Extrusion

The integration of CAD software into the aluminum extrusion process offers numerous benefits that can significantly enhance productivity and efficiency.

Increased Design Accuracy and Reduced Errors

One of the most significant advantages of using aluminum extrusion software is the increased accuracy it provides. Traditional design methods are prone to human error, which can lead to costly mistakes during production. CAD software minimizes these errors by allowing for precise measurements and adjustments, ensuring that the final product matches the intended design.

Time-Saving in the Design Process

Time is a critical factor in manufacturing, and aluminum extrusion software can help streamline the design process. With features such as automated calculations and instant feedback on design changes, users can complete projects more quickly. This efficiency not only accelerates production timelines but also allows companies to take on more projects simultaneously.

Enhanced Collaboration Among Design Teams

In today's interconnected world, collaboration is key to successful project completion. Aluminum extrusion software often includes features that facilitate teamwork, such as cloud-based storage and real-time editing. These tools enable multiple team members to work on a project simultaneously, improving communication and ensuring that everyone is on the same page.

Case Studies

To illustrate the effectiveness of aluminum extrusion software, let's examine a few case studies of companies that have successfully implemented these tools.

Company A: Automotive Industry

Company A, a leading manufacturer in the automotive industry, faced challenges with their aluminum extrusion designs. They implemented advanced aluminum extrusion software that allowed them to create complex profiles with ease. The software's simulation tools enabled them to test their designs under various conditions, resulting in a 30% reduction in production errors and a significant decrease in material waste.

Company B: Aerospace Sector

In the aerospace sector, precision is paramount. Company B adopted aluminum extrusion software to enhance their design capabilities. The software's 3D modeling features allowed their engineers to visualize components in detail, leading to improved aerodynamics and performance. As a result, the company reported a 25% increase in project turnaround times and enhanced product quality.

Company C: Construction Industry

Company C, operating in the construction industry, needed a solution for creating custom aluminum profiles for their projects. By utilizing aluminum extrusion software, they were able to design unique shapes that met specific architectural requirements. The software's customization options allowed them to deliver tailored solutions to their clients, resulting in increased customer satisfaction and repeat business.

Tips for Choosing the Right Software

Selecting the right aluminum extrusion software is crucial for maximizing efficiency and productivity. Here are some tips to consider when making your choice:

Assess Your Needs

Before choosing software, assess your specific needs and requirements. Consider the types of projects you typically work on and the features that would be most beneficial for your design process.

Look for User-Friendly Interfaces

A user-friendly interface can significantly impact your team's productivity. Look for software that is intuitive and easy to navigate, allowing your team to focus on design rather than struggling with complex tools.

Evaluate Customer Support and Training

Good customer support and training resources are essential for successful software implementation. Ensure that the software provider offers comprehensive training materials and responsive support to assist your team as they adapt to the new tools.

Consider Integration with Existing Systems

If your company already uses other software tools, consider how well the aluminum extrusion software integrates with these systems. Seamless integration can enhance workflow and reduce disruptions during the transition.

Read Reviews and Case Studies

Researching reviews and case studies from other users can provide valuable insights into the software's performance and reliability. Look for testimonials from companies in your industry to gauge how well the software meets their needs.

Conclusion

In conclusion, aluminum extrusion software plays a crucial role in enhancing the design and manufacturing processes within the industry. With features such as 3D modeling, simulation tools, and customization options, these software solutions provide significant benefits, including increased accuracy, time savings, and improved collaboration. By selecting the right aluminum extrusion software, companies can streamline their operations, reduce costs, and deliver high-quality products to their clients.

Frequently Asked Questions

1. What is aluminum extrusion software?

Aluminum extrusion software is a specialized tool designed to assist in the design and manufacturing of aluminum profiles. It offers features such as 3D modeling, simulation, and customization options to enhance the extrusion process.

2. How does CAD software improve the aluminum extrusion process?

CAD software improves the aluminum extrusion process by providing accurate design tools, reducing errors, and allowing for simulation of the extrusion process. This leads to more efficient production and higher quality products.

3. What are the key features to look for in aluminum extrusion software?

Key features to look for include 3D modeling capabilities, simulation tools, customization options, user-friendly interfaces, and strong customer support.

4. Can aluminum extrusion software help reduce production costs?

Yes, by increasing design accuracy, reducing material waste, and streamlining the design process, aluminum extrusion software can significantly lower production costs.

5. Are there specific industries that benefit most from aluminum extrusion software?

Industries such as automotive, aerospace, and construction benefit greatly from aluminum extrusion software due to their need for precise, custom designs and efficient manufacturing processes.