Content Menu

● Introduction

● Types of Aluminum Extrusion Connectors

>> T-Slot Connectors

>> Structural Brackets

>> Quick Frame Connectors

>> Modular Aluminum Connectors

>> Heavy-Duty Connectors

>> Adjustable Connectors

>> Aluminum Profile Connectors

● Choosing the Right Connector for Your Project

● Installation Tips and Best Practices

● Case Studies and Applications

● Conclusion

● Related Questions

>> 1. What are the advantages of using aluminum extrusion connectors?

>> 2. How do I determine the load capacity of aluminum extrusion connectors?

>> 3. Can aluminum extrusion connectors be reused?

>> 4. What tools do I need to install aluminum extrusion connectors?

>> 5. Are aluminum extrusion connectors suitable for outdoor use?

Introduction

Aluminum extrusion connectors are essential components in modern construction and DIY projects. They provide the necessary strength and stability to various structures, making them a popular choice among engineers, architects, and hobbyists alike. The versatility of aluminum framing systems allows for a wide range of applications, from industrial machinery to home furniture. In this article, we will explore the different types of aluminum extrusion connectors, how to choose the right one for your project, installation tips, and real-world applications.

Types of Aluminum Extrusion Connectors

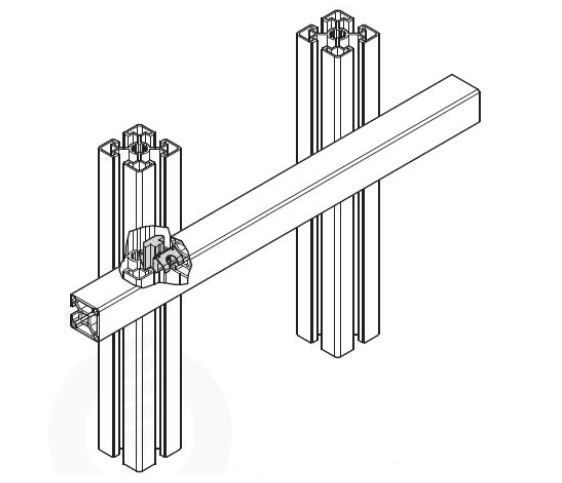

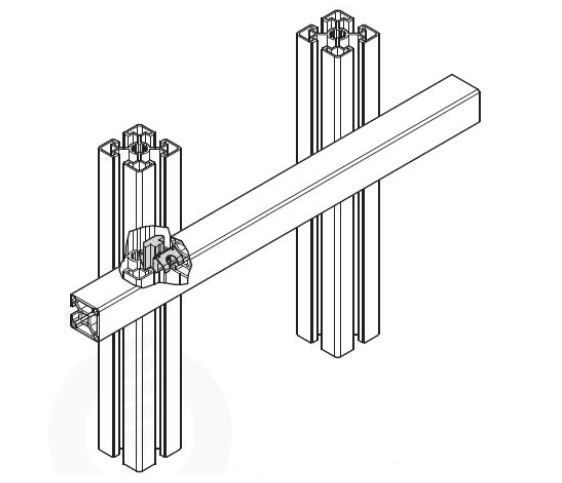

T-Slot Connectors

T-slot connectors are among the most popular types of aluminum extrusion connectors. They are designed to fit into the T-slots of aluminum profiles, allowing for easy assembly and disassembly. These connectors come in various shapes and sizes, including corner brackets, end connectors, and cross connectors.

The primary advantage of T-slot connectors is their flexibility. They can be used to create complex structures without the need for welding or specialized tools. This makes them ideal for projects that require frequent modifications or adjustments. Additionally, T-slot connectors provide a clean and professional appearance, making them suitable for visible applications.

Structural Brackets

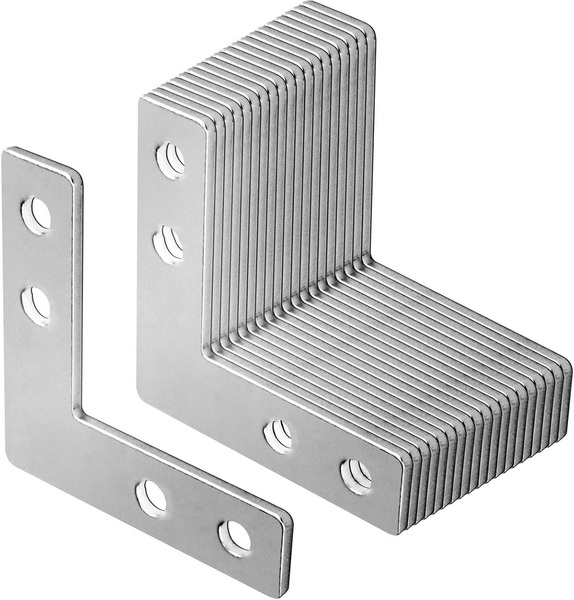

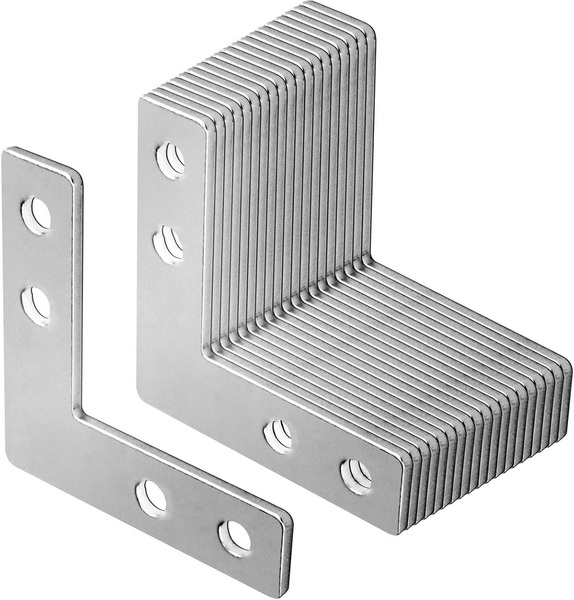

Structural brackets are another essential type of aluminum extrusion connector. They are used to reinforce joints and provide additional support to structures. There are various types of structural brackets, including L-shaped brackets, T-shaped brackets, and flat brackets.

L-shaped brackets are particularly useful for creating right angles in frames, while T-shaped brackets can be used to connect multiple profiles at a single point. Flat brackets are versatile and can be used in various configurations. The choice of bracket depends on the specific requirements of your project, such as load capacity and space constraints.

Quick Frame Connectors

Quick frame connectors are designed for rapid assembly and disassembly of aluminum structures. These connectors allow users to create temporary or permanent frames quickly, making them ideal for exhibitions, displays, and modular furniture.

The primary benefit of quick frame connectors is their ease of use. They typically feature a simple locking mechanism that allows for quick adjustments without the need for tools. This makes them perfect for projects that require frequent changes or updates.

Modular Aluminum Connectors

Modular aluminum connectors are designed for use in modular construction systems. These connectors allow for the easy assembly of pre-fabricated components, making them ideal for large-scale projects.

The advantage of modular connectors is their ability to create complex structures with minimal effort. They can be used to connect multiple aluminum profiles in various configurations, allowing for greater design flexibility. Additionally, modular connectors are often designed to be reusable, making them a sustainable choice for construction projects.

Heavy-Duty Connectors

For projects that require additional strength and stability, heavy-duty connectors are the best choice. These connectors are designed to support larger loads and withstand harsh conditions.

Heavy-duty connectors are typically made from high-strength materials and feature reinforced designs. They are ideal for industrial applications, such as machinery frames and structural supports. When selecting heavy-duty connectors, it is essential to consider the specific load requirements of your project to ensure safety and reliability.

Adjustable Connectors

Adjustable connectors offer the flexibility to modify the angle and position of aluminum profiles after installation. This feature is particularly useful in projects where precise alignment is crucial.

These connectors often include a locking mechanism that allows users to adjust the angle of the profiles easily. Adjustable connectors are ideal for applications such as display stands, where the angle may need to be changed frequently.

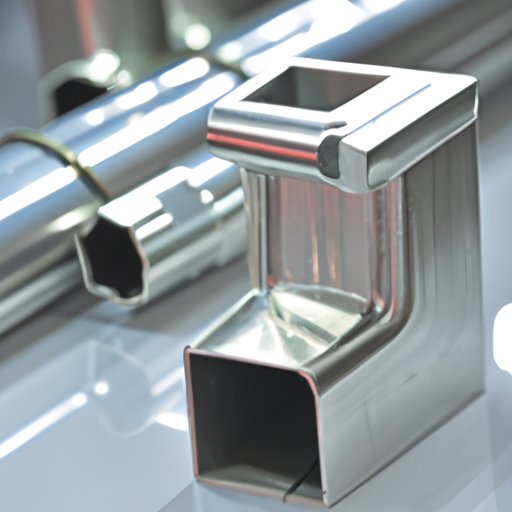

Aluminum Profile Connectors

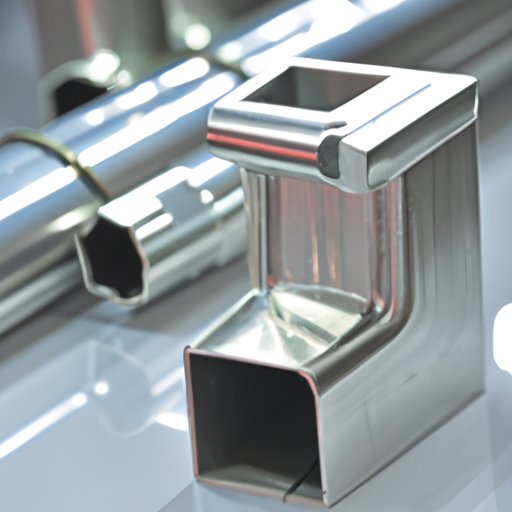

Aluminum profile connectors are designed specifically for connecting aluminum profiles in various configurations. These connectors are available in different shapes, including corner connectors, end connectors, and cross connectors.

The primary advantage of aluminum profile connectors is their ability to create strong and stable joints. They are often used in applications where structural integrity is critical, such as in the construction of frames and supports.

Choosing the Right Connector for Your Project

When selecting aluminum extrusion connectors for your project, several factors should be considered:

- Load Capacity: Determine the weight and stress that the connectors will need to support. This will help you choose connectors that can handle the required load without compromising safety.

- Material Compatibility: Ensure that the connectors are compatible with the aluminum profiles you are using. Different connectors may have specific requirements regarding the type of aluminum used.

- Ease of Installation: Consider how easy it is to install the connectors. Some connectors may require specialized tools or skills, while others can be installed quickly and easily.

- Project Requirements: Think about the specific needs of your project. For example, if you need to frequently adjust the structure, adjustable connectors may be the best choice.

Installation Tips and Best Practices

Installing aluminum extrusion connectors can be straightforward if you follow these tips:

- Prepare Your Materials: Before starting, gather all necessary materials, including connectors, aluminum profiles, and tools. Ensure that everything is clean and free of debris.

- Follow Manufacturer Instructions: Always refer to the manufacturer's guidelines for installation. This will help you avoid common mistakes and ensure a secure fit.

- Use the Right Tools: Depending on the type of connectors you are using, you may need specific tools for installation. Make sure you have the right tools on hand to avoid delays.

- Check Alignment: As you install the connectors, regularly check the alignment of the profiles. This will help you maintain a straight and level structure.

- Test Stability: Once the connectors are installed, test the stability of the structure before putting it to use. This will help you identify any potential issues early on.

Case Studies and Applications

Aluminum extrusion connectors have been used in various successful projects across different industries. Here are a few examples:

- Industrial Machinery: Many manufacturers use aluminum extrusion connectors to create frames for machinery. The lightweight yet strong nature of aluminum allows for efficient designs that can withstand heavy loads.

- Modular Furniture: Designers often use aluminum extrusion connectors to create modular furniture systems. These systems can be easily reconfigured to meet changing needs, making them popular in both residential and commercial settings.

- Exhibition Displays: Quick frame connectors are commonly used in exhibition displays. They allow for rapid assembly and disassembly, making it easy to transport and set up displays at different events.

- Automotive Applications: The automotive industry utilizes aluminum extrusion connectors in various applications, including vehicle frames and components. The lightweight nature of aluminum helps improve fuel efficiency while maintaining structural integrity.

- Architectural Structures: Architects often incorporate aluminum extrusion connectors into their designs for modern buildings. The clean lines and versatility of aluminum framing systems allow for innovative architectural solutions.

Conclusion

Aluminum extrusion connectors are vital components in a wide range of projects, offering strength, versatility, and ease of use. By understanding the different types of connectors available and how to choose the right one for your project, you can create robust and reliable structures. Whether you are working on industrial machinery, modular furniture, or exhibition displays, aluminum extrusion connectors provide the flexibility and stability needed for success.

Related Questions

1. What are the advantages of using aluminum extrusion connectors?

Aluminum extrusion connectors offer several advantages, including lightweight construction, high strength-to-weight ratio, ease of assembly, and versatility in design.

2. How do I determine the load capacity of aluminum extrusion connectors?

To determine the load capacity, consult the manufacturer's specifications for the connectors and consider the weight and stress that the structure will experience during use.

3. Can aluminum extrusion connectors be reused?

Yes, many aluminum extrusion connectors are designed to be reusable, making them a sustainable choice for various projects.

4. What tools do I need to install aluminum extrusion connectors?

The tools required may vary depending on the type of connectors used, but common tools include wrenches, screwdrivers, and Allen keys.

5. Are aluminum extrusion connectors suitable for outdoor use?

Yes, aluminum extrusion connectors are suitable for outdoor use, especially if they are treated to resist corrosion and weathering.