Content Menu

● 1. American Aluminum Extrusions of Ohio, LLC

● 2. BRT Extrusions Inc.

● 3. Talan Products Inc.

● 4. National Extrusion & Manufacturing

● 5. Hydro Extrusion

● 6. Star Extruded Shapes Inc.

● 7. General Aluminum Manufacturing Company (GAMCO)

● 8. Northern States Metals

● The Role of Aluminum Extrusion in Modern Industries

● Conclusion

● FAQ

>> 1. What is the primary process used in aluminum extrusion?

>> 2. What industries commonly use aluminum extrusions?

>> 3. How do I choose the right aluminum extruder?

>> 4. What are some common alloys used in aluminum extrusion?

>> 5. Can I get custom shapes made through an aluminum extruder?

● Citations:

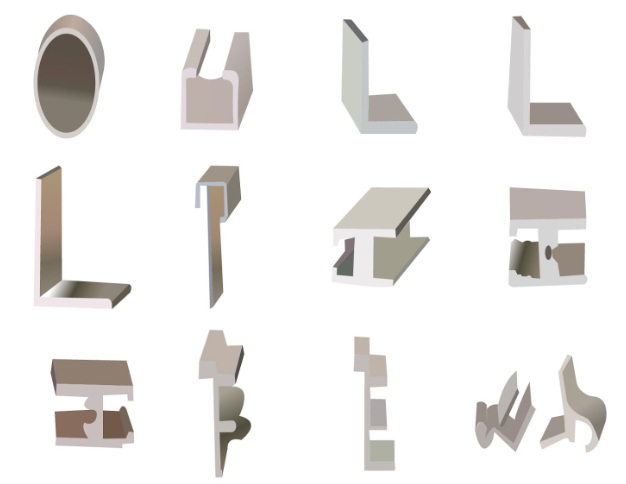

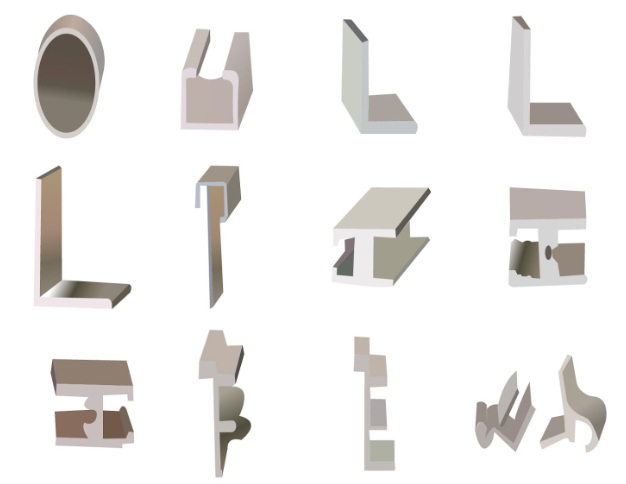

Aluminum extrusion is a vital manufacturing process that shapes aluminum into desired profiles by forcing it through a die. This method is widely used across various industries, including construction, automotive, and electronics. Ohio, with its rich manufacturing history and robust industrial base, is home to several leading aluminum extruders. This article explores the best aluminum extruders in Ohio, highlighting their capabilities, product offerings, and unique features.

1. American Aluminum Extrusions of Ohio, LLC

Located in the heart of Ohio, American Aluminum Extrusions of Ohio, LLC stands out as a premier manufacturer specializing in aluminum extrusions.

- Experience: With years of experience in the industry, they have built a reputation for quality and innovation.

- Product Range: They offer a vast selection of profiles, including standard shapes, custom designs, and specialty profiles tailored for various industries such as construction and transportation.

- Technology: Their state-of-the-art manufacturing facilities are equipped with advanced extrusion presses and precision tooling. They utilize computer-controlled systems to ensure dimensional accuracy and quality control throughout the production process.

- Quality Assurance: They source high-quality aluminum alloys like 6061 and 6063, known for their strength and durability. Rigorous quality control measures are implemented at every production stage to meet or exceed industry standards.

American Aluminum Extrusions of Ohio also provides value-added services such as precision cutting, CNC machining, fabrication, surface finishing, and assembly capabilities. Their commitment to sustainability is evident in their energy-efficient practices and recycling initiatives.

2. BRT Extrusions Inc.

BRT Extrusions Inc., based in Niles, Ohio, is another top contender in the aluminum extrusion market.

- History: With over 150 years of experience in the industry, BRT has established itself as a reliable partner for various sectors including construction and transportation.

- Capabilities: They provide a wide range of extruded products including rods, tubes, and channels designed to meet specific customer needs.

- Commitment to Quality: BRT emphasizes quality assurance with comprehensive testing protocols to ensure that all products meet stringent standards.

BRT's advanced manufacturing processes allow them to produce complex shapes while maintaining high levels of precision. Their focus on customer service ensures that clients receive timely responses and tailored solutions.

3. Talan Products Inc.

Talan Products Inc., located in Cleveland, Ohio, specializes in precision aluminum extrusions.

- ISO Certification: As an ISO 9001 certified vendor, Talan Products ensures high standards of quality in their manufacturing processes.

- Diverse Offerings: Their product line includes custom extruded shapes and standard profiles suitable for various applications across multiple industries.

- Customer Focus: Talan is known for its commitment to customer satisfaction by providing tailored solutions that meet specific requirements.

Talan Products also offers extensive engineering support for clients looking to develop new products or modify existing designs. Their collaborative approach helps streamline the design-to-manufacturing process.

4. National Extrusion & Manufacturing

Founded in 1950 and based in Bellefontaine, Ohio, National Extrusion & Manufacturing has been delivering high-quality custom aluminum extrusions for decades.

- Production Capacity: Their 2,500-ton extrusion press allows them to handle large-scale projects efficiently while maintaining high standards of quality.

- Flexibility: They can produce various sizes and shapes of extrusions using alloys such as 6005, 6063, and 6061.

- Quality Control: Every product undergoes rigorous internal quality checks before shipping to ensure reliability.

National Extrusion & Manufacturing also provides finishing services such as anodizing and painting to enhance the durability and aesthetic appeal of their products. Their commitment to innovation keeps them at the forefront of the aluminum extrusion industry.

5. Hydro Extrusion

Hydro Extrusion is recognized as one of the largest soft alloy aluminum extruders globally and has a significant presence in Ohio.

- Extensive Network: With over 20 locations across North America and more than 60 extrusion presses, Hydro can cater to diverse customer needs effectively.

- Innovative Solutions: They offer both standard and custom shapes up to 22 inches wide and provide extensive value-added services such as CNC machining and assembly.

- Sustainability Focus: Hydro is committed to sustainable practices in its manufacturing processes, aligning with global environmental standards.

Hydro's Sidney facility is equipped with advanced fabrication capabilities that allow them to produce complex components tailored to specific application requirements. Their extensive inventory of alloys enables them to meet a wide range of specifications for various industries including automotive and renewable energy sectors.

6. Star Extruded Shapes Inc.

Star Extruded Shapes Inc., located in Canfield, Ohio, specializes in custom aluminum extrusion solutions.

- Custom Solutions: They focus on providing tailored solutions for complex design challenges across various industries.

- Quality Commitment: Star emphasizes quality assurance through meticulous inspection processes to ensure that all products meet customer specifications.

Star's expertise extends beyond basic extrusion; they offer design assistance that helps clients optimize their designs for manufacturability while maintaining functionality and aesthetics.

7. General Aluminum Manufacturing Company (GAMCO)

Based in Ravenna, Ohio, GAMCO has been a key player in the aluminum manufacturing sector since 1943.

- Contract Manufacturing: GAMCO specializes exclusively in contract manufacturing with a focus on aluminum products.

- Industry Expertise: Their extensive experience allows them to provide valuable insights into the best practices for aluminum extrusion applications.

GAMCO's dedication to customer service ensures that they remain responsive to client needs throughout the production process. They also maintain strong relationships with suppliers to secure high-quality raw materials essential for producing superior products.

8. Northern States Metals

Located in Columbus, Ohio, Northern States Metals has carved out a niche within the aluminum extrusion market by focusing on both manufacturing and product design services.

- Dual Focus: This company not only manufactures standard extrusions but also engages in product design services which help clients develop innovative solutions tailored specifically for their applications.

- Quality Assurance Practices: Northern States Metals employs stringent quality control measures throughout its operations to guarantee product consistency and reliability across all orders.

Their collaborative approach with clients fosters innovation while ensuring that products meet rigorous industry standards.

The Role of Aluminum Extrusion in Modern Industries

The demand for aluminum extrusions continues to grow across various sectors due to several key factors:

- Lightweight Materials: The automotive industry increasingly seeks lightweight materials like aluminum to enhance fuel efficiency without sacrificing strength or durability. Aluminum's high strength-to-weight ratio makes it an ideal choice for vehicle components such as frames and body panels[3].

- Construction Applications: In construction, aluminum's corrosion resistance makes it an excellent material for building facades, windows, doors, and structural components[3]. Its versatility allows architects to create innovative designs while ensuring longevity[6].

- Technological Advancements: The aluminum extrusion process has benefited from technological advancements such as CNC machining and automated handling systems that improve efficiency while reducing costs[3]. These innovations enable manufacturers to produce complex shapes with precision at scale[6].

Conclusion

Ohio boasts a rich landscape of aluminum extruders that cater to diverse industry needs. Companies like American Aluminum Extrusions of Ohio LLC, BRT Extrusions Inc., Talan Products Inc., National Extrusion & Manufacturing, Hydro Extrusion, Star Extruded Shapes Inc., GAMCO, and Northern States Metals exemplify excellence through their commitment to quality and innovation.

These manufacturers not only provide high-quality products but also offer value-added services that enhance customer satisfaction. Whether you require standard shapes or custom designs for specialized applications, these companies are well-equipped to meet your needs with precision and reliability.

The future looks promising for the aluminum extrusion industry in Ohio as it continues adapting to market demands while embracing sustainable practices that align with global trends towards environmental responsibility.

FAQ

1. What is the primary process used in aluminum extrusion?

Aluminum extrusion involves forcing heated aluminum alloy through a die to create specific cross-sectional profiles. This process allows for intricate designs that are difficult to achieve with other methods.

2. What industries commonly use aluminum extrusions?

Aluminum extrusions are widely used in construction, automotive manufacturing, electronics production, aerospace applications, and many other sectors due to their versatility and strength.

3. How do I choose the right aluminum extruder?

When selecting an aluminum extruder, consider factors such as their experience in your industry, quality certifications (like ISO), production capabilities (including size limits), and additional services offered (like CNC machining or assembly).

4. What are some common alloys used in aluminum extrusion?

Common alloys used include 6061 (known for its strength), 6063 (often used for architectural applications), and 6005 (used for structural components). Each alloy has unique properties suitable for different applications.

5. Can I get custom shapes made through an aluminum extruder?

Yes! Most reputable aluminum extruders offer custom shape fabrication services tailored to meet specific design requirements or project demands.

Citations:

[1] https://www.zetwerk.com/resources/knowledge-base/aluminum-extrusions/top-aluminum-extrusion-suppliers-in-the-usa/

[2] https://aluminum-extrusions.net/american-aluminum-extrusions-of-ohio-llc/

[3] https://markwideresearch.com/united-states-aluminum-extrusion-market/

[4] https://clutch.co/logistics/manufacturing-companies/aluminum/ohio

[5] https://brtextrusions.com

[6] https://www.hydro.com/profiles/custom-aluminum-extrusions-in-ohio

[7] https://www.thomasnet.com/suppliers/northern-ohio/all-cities/aluminum-extrusions-26890400

[8] https://www.iqsdirectory.com/aluminum-extruders/ohio/

[9] https://genext.com

[10] https://www.ibisworld.com/us/industry/ohio/aluminum-manufacturing/35002/

[11] https://www.fonnovaluminium.com/top-10-aluminum-extrusion-manufacturers-in-the-united-states.html

[12] https://www.aluminum.org/sites/default/files/2021-11/StateRegionReport3Q2021.pdf

[13] https://aluminumextruderscoalition.com/news/

[14] https://www.extrusions.com

[15] https://www.recyclingtoday.com/news/atomic-13-reshaping-the-aluminum-extrusion-industry/

[16] https://www.hydro.com/en/global/about-hydro/hydro-worldwide/americas/united-states/midwest/hydro-sidney-oh/

[17] https://starext.com/category/news

[18] https://members.aec.org

[19] https://www.einnews.com/pr_news/772176066/aluminum-extrusion-market-size-shares-business-growth-and-upcoming-trends-forecast-by-2024-2031-hindalco-industries

[20] https://aec.org/domestic-supply