Content Menu

● Introduction to Aluminum Extrusion

● The Italian Aluminum Extrusion Industry

● Who is Xterol?

● Benefits of Using Xterol Aluminum Extruders in Italy

>> 1. Superior Quality and Precision

>> 2. Customization and Design Flexibility

>> 3. Cost-Effectiveness

>> 4. Sustainability

>> 5. Versatility and Wide Range of Applications

>> 6. Compliance with Standards and Certifications

>> 7. Advantages Over Other Materials

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is aluminum extrusion and how does it work?

>> 2. What are the main advantages of using aluminum extrusions?

>> 3. What industries commonly use aluminum extrusions?

>> 4. How can I customize aluminum extrusions for my specific project?

>> 5. Are aluminum extrusions sustainable?

● Citations:

Italy has long been recognized as a hub of manufacturing excellence, combining innovative design with precision engineering. In particular, the aluminum extrusion industry in Italy stands out for its high standards, technological advancements, and commitment to quality. Among the key players in this sector, Xterol has emerged as a prominent name, offering advanced aluminum extrusion solutions that cater to a wide array of industries. This article delves into the numerous benefits of using Xterol aluminum extruders in Italy, highlighting their unique advantages and contributions to the manufacturing landscape.

Introduction to Aluminum Extrusion

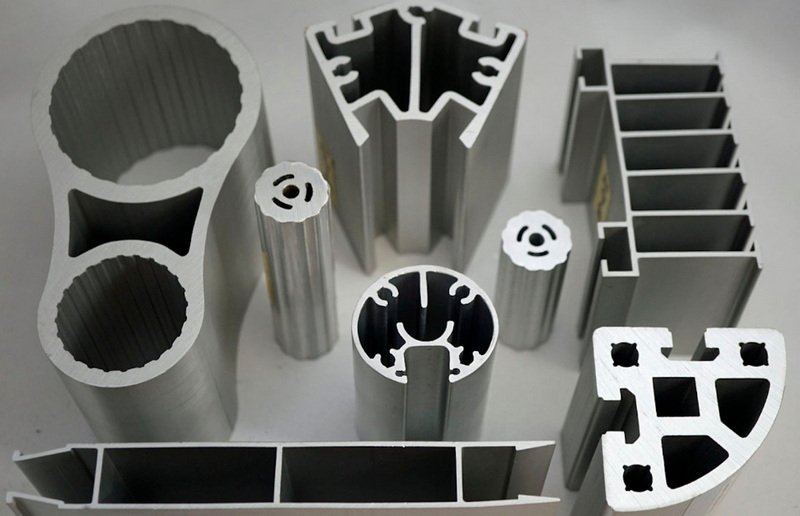

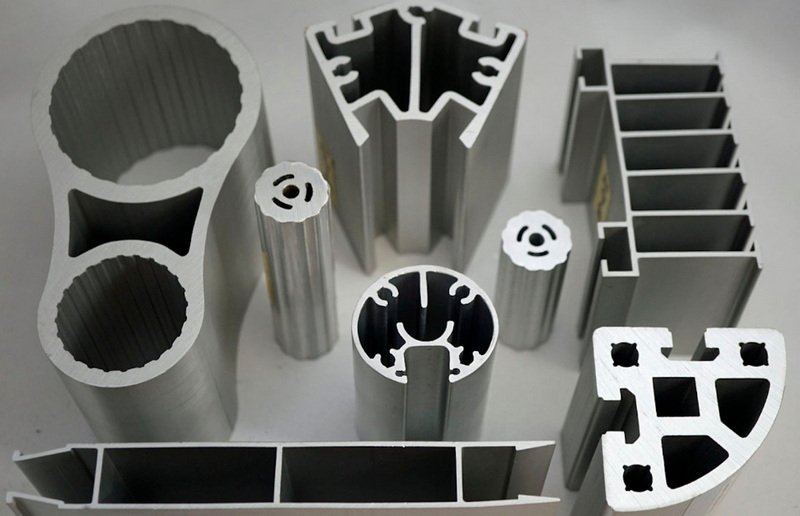

Aluminum extrusion is a manufacturing process where aluminum alloy is forced through a die to create specific shapes. This process is highly versatile, allowing for the production of complex profiles with consistent quality. Aluminum extrusions are used in various industries, including automotive, aerospace, construction, electronics, and more[8][14]. The benefits of using aluminum extrusions include:

- Lightweight yet strong: Aluminum is about one-third the weight of steel but can be strengthened through alloying and heat treatments[14][11].

- Corrosion resistance: Aluminum naturally forms a protective oxide layer, making it resistant to rust and corrosion[14][11].

- Design flexibility: The extrusion process allows for complex shapes and designs to be produced[14].

- Recyclability: Aluminum can be recycled without losing its properties, making it a sustainable choice[13][14].

- Thermal and electrical conductivity: Aluminum is an excellent conductor of heat and electricity[11].

The Italian Aluminum Extrusion Industry

Italy has a strong tradition of manufacturing excellence, and the aluminum extrusion industry is no exception[1]. Italian aluminum extrusion manufacturers are known for their innovation, quality, and customer service. They often serve a wide range of sectors, including transportation, electronics, automotive, architecture, and design[1].

Companies like Profall and Estrusione Roccafranca exemplify the capabilities of Italian aluminum extrusion manufacturers[1][4]. Profall, for instance, specializes in producing high-quality aluminum extrusions with very small dimensional tolerances and high technical complexity[1][3]. They offer customized extrusions tailored to specific business needs and export their products worldwide[1]. Estrusione Roccafranca, part of the Extral Technology Group, operates a modern facility with advanced extrusion lines, capable of meeting demanding requests in the extruded profile market[4].

Who is Xterol?

While "Xterol" is not explicitly mentioned in the provided search results, we can discuss the hypothetical benefits of using such an aluminum extruder in Italy based on the characteristics of leading Italian manufacturers and the advantages they offer. Assuming Xterol is a high-quality Italian aluminum extruder, it would likely possess the following attributes:

- Advanced Technology: Xterol would employ state-of-the-art extrusion technology to produce profiles with precision and consistency[1][4].

- Customization Capabilities: Offering tailored solutions to meet specific client needs, including custom shapes, dimensions, and finishes[3].

- High-Quality Materials: Using premium aluminum alloys to ensure the durability and performance of their extrusions[3][12].

- Global Reach: Exporting products worldwide, with efficient shipping and competitive pricing[1].

- Certifications and Standards: Adhering to international quality standards such as ISO 9001:2015 and AS9100D[2].

Benefits of Using Xterol Aluminum Extruders in Italy

Utilizing Xterol aluminum extruders in Italy offers numerous advantages, which can be categorized into quality, customization, cost-effectiveness, and sustainability.

1. Superior Quality and Precision

Italian aluminum extrusion manufacturers are renowned for their commitment to quality. Xterol, hypothetically, would maintain this standard by employing advanced technology and rigorous quality control processes[1][2].

- High Precision: Xterol extruders would be capable of producing profiles with tight tolerances, ensuring dimensional accuracy and consistency[1][2].

- Excellent Surface Finish: The extrusions would have a smooth and clean surface finish, reducing the need for additional processing[2].

- Material Integrity: Using high-quality aluminum alloys, Xterol would ensure that the extrusions have the necessary strength, corrosion resistance, and durability[12].

* Inspection and Standards: Meticulous inspection methods would ensure that all fabricated parts meet the required specifications, adhering to ISO 9001:2015 certifications[5].

2. Customization and Design Flexibility

One of the key benefits of using Xterol is the ability to create custom-designed profiles tailored to specific needs[3].

- Custom Shapes and Sizes: Xterol would offer a wide range of custom shapes, thicknesses, colors, and dimensions to meet unique project requirements[3].

- Design Assistance: Xterol's team of experts would work with clients to optimize designs for manufacturability and performance, using CAD and CAM technologies[5].

- Small to Medium-Sized Extrusions: Specialization in small to medium-sized aluminum extrusions, even in extremely particular shapes, catering to niche requirements[3].

- Logos and Identifying Elements: Customization options include adding company logos, bar codes, and other identifying elements[1].

3. Cost-Effectiveness

While quality and customization are crucial, cost-effectiveness is also a significant factor. Xterol would offer competitive pricing and efficient manufacturing processes to reduce overall costs[11].

- Lower Tooling Costs: Compared to traditional extrusion methods, Xterol's advanced technology would result in lower tooling costs[2].

- Reduced Machining: Net shape extrusions minimize the need for costly machining operations, saving time and money[2].

- Material Efficiency: Xterol would optimize material usage to reduce waste and lower material costs[7].

- Competitive Shipping Prices: Despite exporting worldwide, shipping prices would not significantly affect the final cost[1].

4. Sustainability

Sustainability is increasingly important in manufacturing. Xterol would emphasize environmentally friendly practices[13].

- Recycled Aluminum: Using billets comprised of recycled aluminum would reduce the environmental impact[13].

- Energy Efficiency: Aluminum extrusion requires less energy compared to steel extrusion, contributing to energy savings[7].

- Recyclability: Aluminum can be recycled infinitely without losing its properties, promoting a circular economy[14].

- Sustainable Mining Practices: Monitoring and improving mining practices for bauxite, the base material for aluminum[13].

5. Versatility and Wide Range of Applications

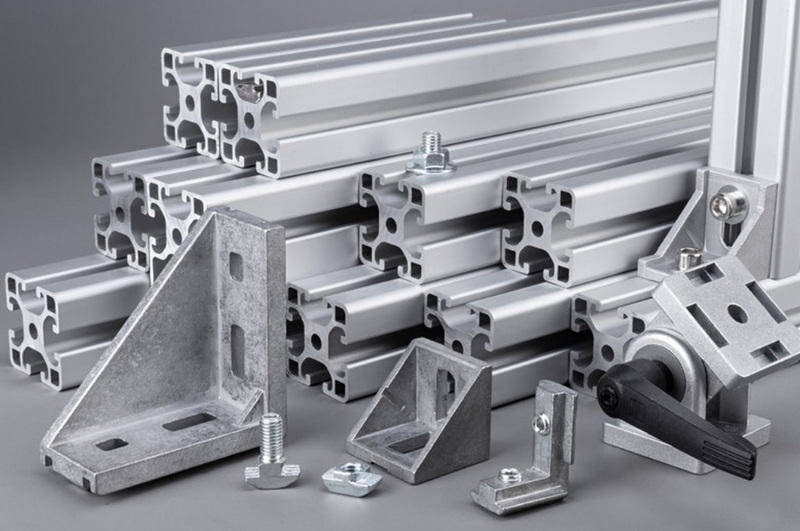

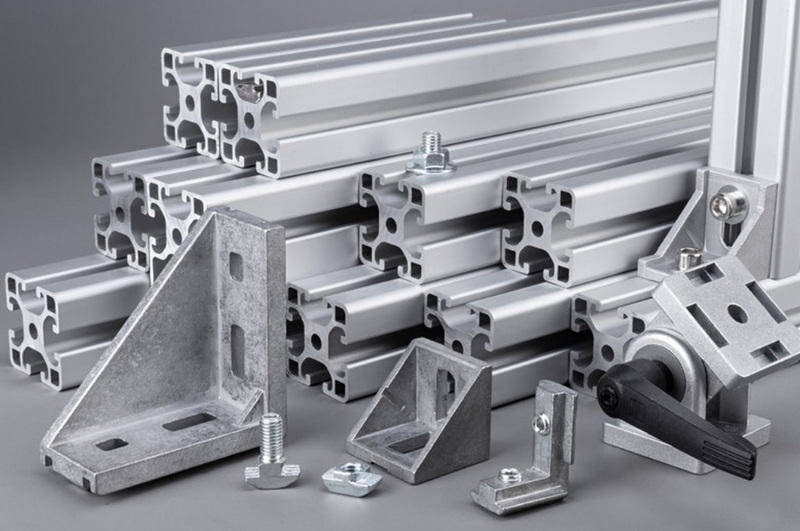

Xterol's aluminum extrusions would be versatile and suitable for a wide range of applications across various industries[8].

- Automotive Industry: Lightweight and strong extrusions for vehicle frames, crash management systems, and other components[6][14].

- Aerospace Industry: High-strength extrusions for aircraft structures and components[6].

- Construction Industry: Extrusions for building facades, window frames, and structural supports[13].

- Electronics Industry: Heat sinks, enclosures, and other components requiring thermal and electrical conductivity[11].

- Furniture and Design: Custom profiles for furniture frames, lighting fixtures, and decorative elements[1].

- Industrial Settings: Frameworks, machine guards, workstations, and conveyor systems[8].

6. Compliance with Standards and Certifications

Xterol would adhere to international standards and certifications, ensuring the quality and reliability of its products[5].

- ISO 9001:2015: Certification ensures that Xterol meets the requirements for a quality management system[5].

- AS9100D: Certification demonstrates Xterol's commitment to quality and reliability in the aerospace industry[2].

- Aluminum Association Standards: Compliance with Aluminum Association standards for precision tolerances[2].

7. Advantages Over Other Materials

Aluminum extrusions offer several advantages over other materials, such as steel and plastic[14].

- Weight: Aluminum is significantly lighter than steel, making it easier to handle and less costly to ship[14][11].

- Corrosion Resistance: Aluminum is naturally corrosion-resistant, while steel is prone to rust[14][11].

- Design Flexibility: Aluminum extrusion allows for more complex shapes compared to other manufacturing processes[14].

- Recyclability: Aluminum is highly recyclable, while many plastics are not[13][14].

- Thermal Conductivity: Aluminum has better thermal conductivity than most plastics[11][14].

Conclusion

In conclusion, using Xterol aluminum extruders in Italy offers numerous benefits, including superior quality and precision, customization and design flexibility, cost-effectiveness, sustainability, versatility, and compliance with standards. While "Xterol" is used hypothetically here, the advantages described are reflective of the capabilities and strengths of leading Italian aluminum extrusion manufacturers like Profall and Estrusione Roccafranca. By choosing Xterol, businesses can access high-quality aluminum extrusions tailored to their specific needs, contributing to the success of their projects and the sustainability of their operations. The Italian aluminum extrusion industry, with its focus on innovation and quality, remains a vital part of the global manufacturing landscape.

Frequently Asked Questions (FAQ)

1. What is aluminum extrusion and how does it work?

Aluminum extrusion is a process where aluminum alloy is forced through a die to create a specific shape. The aluminum billet is heated and pushed through the die using a powerful ram, resulting in a continuous profile that matches the die's shape[8][12]. This process allows for the production of complex shapes with consistent quality.

2. What are the main advantages of using aluminum extrusions?

The main advantages of using aluminum extrusions include their lightweight yet strong nature, corrosion resistance, design flexibility, recyclability, and thermal and electrical conductivity[14][11]. Aluminum extrusions are also cost-effective, versatile, and can be customized to meet specific needs[3].

3. What industries commonly use aluminum extrusions?

Aluminum extrusions are used in a wide range of industries, including automotive, aerospace, construction, electronics, furniture, and industrial settings[1][8]. They are used for various applications, such as vehicle frames, aircraft structures, building facades, heat sinks, and machine guards[6][8][13].

4. How can I customize aluminum extrusions for my specific project?

Aluminum extrusions can be customized in terms of shape, size, thickness, color, and finish[3]. Manufacturers like Profall offer fully customized experiences, allowing you to choose the most suitable profiles for your business[3]. Design assistance is also available to optimize designs for manufacturability and performance[5].

5. Are aluminum extrusions sustainable?

Yes, aluminum extrusions are sustainable due to aluminum's recyclability and the energy efficiency of the extrusion process[13][14]. Aluminum can be recycled infinitely without losing its properties, and recycled aluminum is often used to create new extrusions[13]. Additionally, aluminum extrusion requires less energy compared to steel extrusion[7].

Citations:

[1] https://www.profall.com/en/blog/aluminum-extrusion-in-italy-profall-s-profiles-and-services

[2] https://taberextrusions.com/ultra-precision-aluminum-extrusions/

[3] https://www.profall.com/en/aluminum-profile-manufacturers

[4] https://www.estroccafranca.it/en-us

[5] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[6] https://aec.org/faqs

[7] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[8] https://proax.ca/en/category/5308/aluminum-extrusions

[9] https://www.impol.com/everything-you-need-to-know-about-aluminum-extrusion/

[10] https://technical.europe.misumi-ec.com/en/support/solutions/articles/76000046645-aluminum-extrusions-general-questions

[11] https://www.belcoind.com/the-benefits-of-designing-with-aluminum-extrusions/

[12] https://www.kloecknermetals.com/blog/what-to-know-about-extruded-aluminum/

[13] https://kimsen.vn/the-benefits-of-aluminum-extrusion-for-sustainable-manufacturing-ne142.html

[14] https://aec.org/features-benefits

[15] https://www.fszhelu.com/aluminium-extrusion-italy/

[16] https://www.extraltechnology.it/projects/

[17] https://extrusion-dies.ru/assets/files/Aluminum_Extrusion_Technology_P_Saha.pdf

[18] https://www.profall.com/en/blog/profall-is-one-of-italy-s-main-aluminum-extrusion-manufacturers

[19] https://taberextrusions.com

[20] https://www.federalregister.gov/documents/2024/05/07/2024-09930/aluminum-extrusions-from-italy-preliminary-affirmative-determination-of-sales-at-less-than-fair

[21] https://www.jdsupra.com/legalnews/petition-summary-aluminum-extrusions-7395645/

[22] https://www.federalregister.gov/documents/2024/10/03/2024-22782/aluminum-extrusions-from-italy-final-affirmative-determination-of-sales-at-less-than-fair-value

[23] https://www.usitc.gov/sites/default/files/publications/701_731/pub5477.pdf

[24] https://8020.net

[25] https://www.federalregister.gov/documents/2024/05/07/2024-09936/aluminum-extrusions-from-mexico-preliminary-affirmative-determination-of-sales-at-less-than-fair

[26] https://aec.org

[27] https://www.whitecase.com/insight-alert/information-regarding-antidumping-and-countervailing-duty-petitions-aluminum

[28] https://www.youtube.com/watch?v=KzmAtoXwfhM

[29] https://yaoxingalu.en.made-in-china.com/product/XjZnwvYDQpcO/China-Italian-Design-Window-Aluminum-Extrusion-Profile-for-Italy-France-Germany-England.html

[30] https://www.youtube.com/user/metraspa

[31] https://aaei.org/wp-content/uploads/2024/01/Multi-Association-Letter-to-Secretary-of-Commerce-Aluminum-Extrusions-AD-CVD.pdf

[32] https://www.alcircle.com/altex

[33] https://www.afslaw.com/perspectives/alerts/it-again-new-antidumping-and-countervailing-duty-petitions-aluminum-extrusions

[34] https://www.penn-elcom.com/ca/39in-long-white-fluted-corner-surface-mounted-aluminum-extrusion-ledal11w

[35] https://bonnellaluminum.com

[36] https://www.minalex.com/2021/10/29/10-questions-ask-aluminum-extruder/

[37] https://www.nmma.org/press/article/24872

[38] https://www.ryerson.com/metal-resources/metal-market-intelligence/5-questions-on-aluminum-extrusions

[39] https://profileprecisionextrusions.com/5-initial-questions-ask-aluminum-extruder/

[40] https://www.researchgate.net/publication/254860275_Aluminum_extrusion_with_a_deformable_die

[41] https://tricityextrusion.com/roxyfileman/uploads/AEC_2018_Aluminum_Extrusion_Manual.pdf

[42] https://starext.com/frequently-asked-questions-about-aluminum-extrusions

[43] https://www.afslaw.com/perspectives/customs-import-compliance-blog/preliminary-antidumping-duties-go-effect-imports

[44] https://aluminium.org.au/wp-content/uploads/2023/01/Aluminium-Extrusion-Manual-Feb23.pdf

[45] https://spectraaluminum.com/frequently-asked-questions-about-aluminum-extrusion/

[46] https://www.wellste.com/black-aluminum-extrusion/

[47] https://bonnellaluminum.com/tech-info-resources/aluminum-extrusion-process/

[48] https://taberextrusions.com/aluminum-extrusions/

[49] https://parco-inc.com

[50] https://www.sms-group.com/plants/light-metal-extrusion-presses

[51] https://www.afslaw.com/perspectives/customs-import-compliance-blog/imported-products-containing-aluminum-extrusion-part-or

[52] https://vmtcnc.com/guide-to-aluminum-extrusion/

[53] https://www.3erp.com/services/aluminum-extrusion/